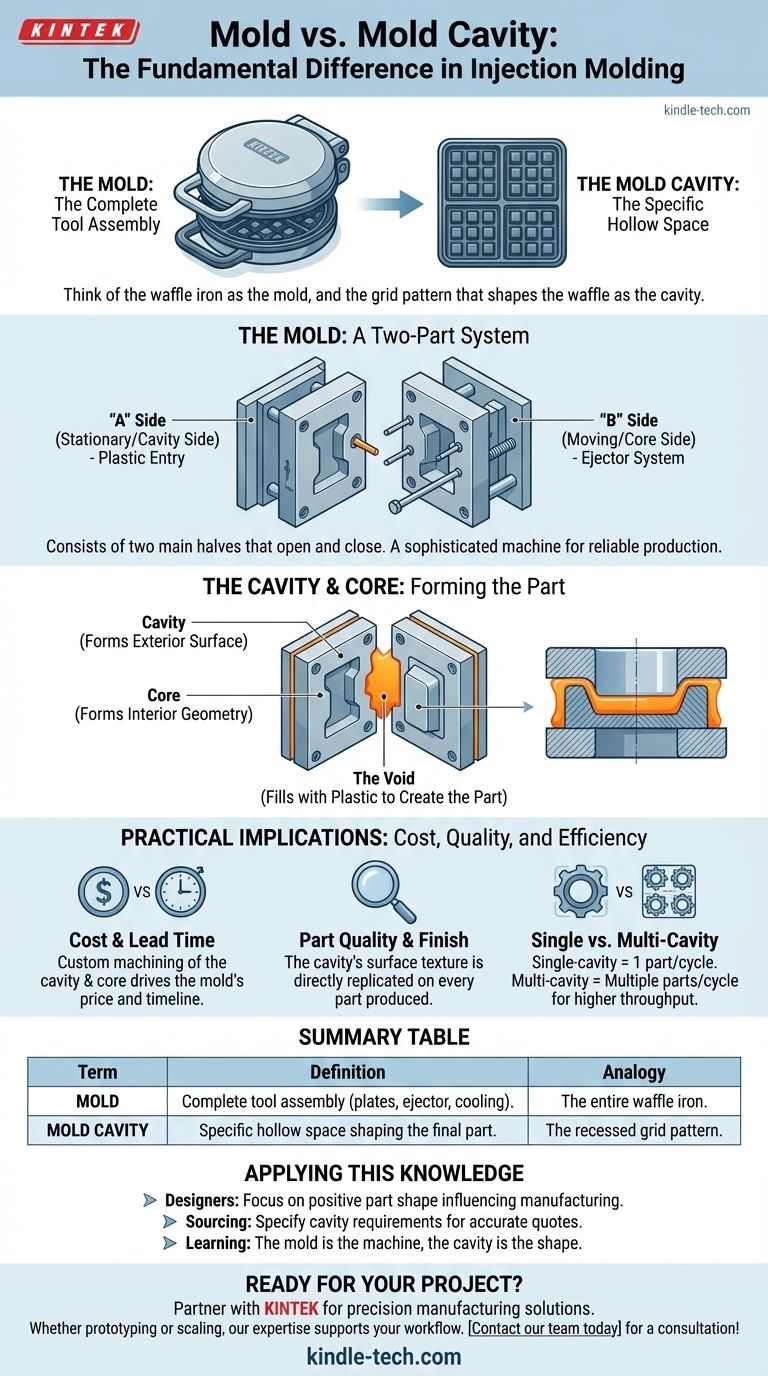

In injection molding, the mold refers to the entire, complex tool assembly used in the manufacturing process. The mold cavity is the specific, hollowed-out space within that mold that is shaped precisely like the final part you intend to create.

The simplest way to understand the difference is through an analogy: The mold is the entire waffle iron, including the handles, hinges, and plates. The mold cavity is just the recessed grid pattern on the inside that gives the waffle its shape.

The Mold: A Complete Tooling System

To grasp the distinction, you must first appreciate that a mold is not a simple block of metal. It is a sophisticated piece of machinery composed of many interconnected parts designed for a single purpose: to produce a part repeatably and reliably.

The Mold as a Two-Part Assembly

A typical injection mold consists of two primary halves. These are often called the "A" side and the "B" side.

The "A" side, also known as the stationary half or cavity side, is mounted to the stationary platen of the molding machine and contains the path for the molten plastic to enter.

The "B" side, also known as the moving half or core side, is mounted to the moving platen. This side usually contains the ejector system that pushes the finished part out of the mold after it has cooled.

The Cavity and Core: Forming the Negative Space

The term mold cavity technically refers to the recessed area, usually in the "A" side of the mold, that forms the exterior, cosmetic surface of the plastic part.

Working in tandem with the cavity is the core, which is the raised portion of the "B" side that forms the interior geometry of the part.

When the mold is closed, the space between the cavity and the core creates the exact negative shape of the final component. It is this void that is filled with molten plastic.

Understanding the Practical Implications

Distinguishing between the mold and the cavity is not just a matter of semantics. It has direct consequences for cost, quality, and production efficiency.

Impact on Cost and Lead Time

The mold base and other standard components are often pre-fabricated. The true cost and time driver of a new mold is the custom machining of the cavity and core.

The complexity of these features—such as undercuts, fine details, and required surface finishes—directly dictates the price and lead time of the entire mold tool.

Impact on Part Quality

The walls of the cavity and core are what the molten plastic touches. Therefore, the surface finish of the cavity directly translates to the surface finish of your part.

A highly polished cavity results in a glossy part, while a textured cavity creates a textured part. Any imperfection in the cavity will be replicated on every single piece produced.

Single vs. Multi-Cavity Molds

A single mold can be designed to have more than one cavity.

A single-cavity mold produces one part per cycle. A multi-cavity mold produces multiple parts per cycle, drastically increasing production throughput. This decision is a key trade-off between higher upfront tooling cost and lower per-part cost at volume.

Applying This to Your Project

Understanding these terms allows you to communicate effectively with designers, engineers, and manufacturers. Use this knowledge to guide your decisions.

- If your primary focus is designing a new part: Remember you are designing the positive shape that must be created by a negative cavity and core, which influences design-for-manufacturability rules.

- If your primary focus is sourcing manufacturing: Specify your requirements for the cavity (surface finish, number of cavities) to get an accurate quote for the complete mold.

- If your primary focus is simply learning: Solidify this idea: the mold is the machine, and the cavity is the shape-defining void within it.

Mastering this fundamental distinction is the first step toward speaking the language of modern manufacturing.

Summary Table:

| Term | Definition | Analogy |

|---|---|---|

| Mold | The complete tool assembly, including plates, ejector system, and cooling channels. | The entire waffle iron. |

| Mold Cavity | The specific hollow space within the mold that shapes the final part. | The recessed grid pattern inside the waffle iron. |

Ready to bring your injection molding project to life?

Understanding the nuances of mold design is critical for success. At KINTEK, we specialize in providing the high-quality lab equipment and consumables needed for precision manufacturing and R&D. Whether you're prototyping a new part or scaling up production, our expertise supports your entire workflow.

Let's discuss your project requirements and how our solutions can help you achieve superior results. Contact our team today for a consultation!

Visual Guide

Related Products

- Isostatic Molding Pressing Molds for Lab

- High-Purity Titanium Foil and Sheet for Industrial Applications

- Custom PTFE Wafer Holders for Lab and Semiconductor Processing

- Vacuum Induction Melting Spinning System Arc Melting Furnace

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- What is Mould filling analysis? Predict Injection Molding Defects Before Cutting the Mold

- What challenges do Swagelok-type cell molds address in NVPF testing? Enhance Accuracy with Precise Pressure & Sealing

- What are the primary functions of PEEK test molds? Essential Tools for All-Solid-State Battery Assembly

- What are the primary functions of graphite molds? Optimize Your Cu-Ti3SiC2 Composite Sintering Today

- What is the primary function of mold pressing for LAGP powders? Achieve High-Performance Solid Electrolytes

- What are the critical performance requirements for hot pressing molds? Ensure Precision in Magnesium Alloy Processing

- What is the core role of specialized pressurized battery test cell dies? Optimizing All-Solid-State Battery Testing

- What are the parts of a mold assembly? A Guide to Injection Mold Components