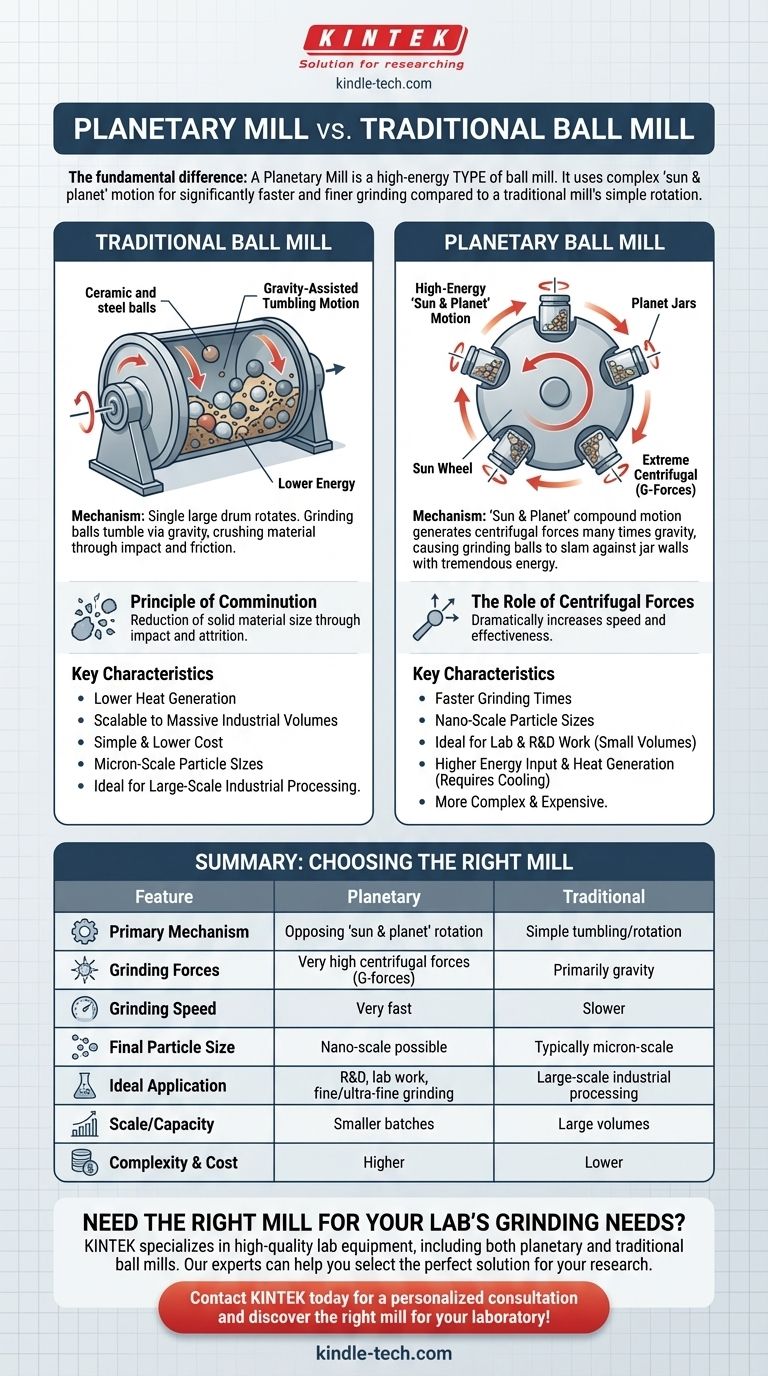

The fundamental difference is that a planetary mill is a specific, high-energy type of ball mill. While a traditional ball mill uses a simple rotating drum, a planetary mill uses a more complex "sun and planet" motion to generate significantly higher forces, resulting in faster and finer grinding.

The core distinction is not one of category, but of mechanism and intensity. A planetary mill is a specialized ball mill that uses compound rotational forces to achieve high-energy grinding, whereas the term "ball mill" can also refer to simpler, lower-energy tumbling mills.

Understanding the Core Mechanism: Ball Milling

How a Traditional Ball Mill Works

A traditional ball mill, often called a rotary or tumbling mill, consists of a single large cylindrical jar that rotates on its horizontal axis.

Inside the jar are the material to be ground and the grinding media—typically hard ceramic or steel balls. As the jar rotates, the balls are lifted up the side and then cascade or tumble down, crushing and grinding the material through impact and friction. The primary force at play is gravity.

The Principle of Comminution

Both types of mills operate on the principle of comminution, which is the reduction of solid material size. The moving balls create immense pressure at their contact points, breaking apart the material particles. This process relies on both impact (balls hitting the material) and attrition (friction from balls sliding against the material).

The Planetary Mill: A High-Energy Evolution

The "Sun and Planet" Motion

A planetary ball mill features one or more grinding jars arranged eccentrically on a rotating disc, known as the sun wheel.

The key is its compound motion: the sun wheel rotates in one direction, while the individual grinding jars (the "planets") rotate on their own axes in the opposite direction.

The Role of Centrifugal Forces

This opposing rotation generates extremely powerful centrifugal forces, also known as G-forces. These forces are many times greater than gravity.

This causes the grinding balls inside the jars to slam against the inner wall with tremendous energy, dramatically increasing the speed and effectiveness of the grinding process compared to a simple tumbling mill.

Key Performance Advantages

The high kinetic energy achieved in a planetary mill leads to several distinct advantages. It allows for significantly faster grinding times and the ability to reduce materials down to very fine, often nanometer-scale, particle sizes that are impossible to achieve with traditional ball mills.

Understanding the Trade-offs

Energy Consumption and Heat

The high-energy input of a planetary mill generates significant heat. This can be a major issue for temperature-sensitive materials and may require external cooling systems. Traditional mills generate far less heat due to their lower energy profile.

Scale and Capacity

Planetary mills are typically used for smaller volumes, making them ideal for laboratory work, research and development, and pilot-scale production. In contrast, traditional tumbling ball mills can be scaled to massive industrial sizes for processing tons of material per hour, such as in mining or cement production.

Complexity and Cost

The sophisticated gearing and mechanics of a planetary mill make it more complex and generally more expensive than a simple rotary ball mill of a similar capacity. Maintenance can also be more involved.

Choosing the Right Mill for Your Application

Selecting the correct mill depends entirely on your final goal for the material.

- If your primary focus is research, high-purity applications, or achieving nano-sized particles: A planetary ball mill is the superior choice for its speed, efficiency, and fine-grinding capability.

- If your primary focus is large-scale industrial grinding or processing bulk materials where micron-size is sufficient: A traditional rotary or tumbling ball mill offers the most practical, scalable, and cost-effective solution.

Understanding this distinction empowers you to select the precise tool that aligns with your material processing goals.

Summary Table:

| Feature | Planetary Ball Mill | Traditional Ball Mill |

|---|---|---|

| Primary Mechanism | Opposing 'sun & planet' rotation | Simple tumbling/rotation |

| Grinding Forces | Very high centrifugal forces (G-forces) | Primarily gravity |

| Grinding Speed | Very fast | Slower |

| Final Particle Size | Nano-scale possible | Typically micron-scale |

| Ideal Application | R&D, lab work, fine/ultra-fine grinding | Large-scale industrial processing |

| Scale/Capacity | Smaller batches | Large volumes |

| Complexity & Cost | Higher | Lower |

Need the Right Mill for Your Lab's Grinding Needs?

Choosing between a planetary mill and a traditional ball mill is critical for achieving your desired particle size and research outcomes. KINTEK specializes in providing high-quality lab equipment, including planetary ball mills for high-energy grinding and traditional ball mills for standard applications. Our experts can help you select the perfect solution to enhance your research efficiency and material processing results.

Contact KINTELK today for a personalized consultation and discover the right mill for your laboratory!

Visual Guide

Related Products

- High Energy Planetary Ball Mill Milling Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Milling Machine for Laboratory

- High Energy Planetary Ball Mill for Laboratory Horizontal Tank Type Milling Machine

- High-Energy Omnidirectional Planetary Ball Mill Machine for Laboratory

- High Energy Planetary Ball Mill Milling Machine for Laboratory

People Also Ask

- How does a planetary ball mill facilitate the Mechanochemical Synthesis of sulfide solid electrolytes? - Anneal-Free

- What role does a planetary ball mill play in the production of nano-scale LLZTO ceramic fillers? Unlocking Nano-Conductivity

- Why is a heating ball mill reactor utilized for scheelite leaching? Overcome Passivation for Maximum Yield

- What is the role of a high-energy planetary ball mill in Al-4Cu preparation? Achieve 30nm Grain Refinement

- What is the role of a planetary ball mill in A356/SiCp composite prep? Achieving Perfect Micro-Structural Homogeneity

- What role does a planetary ball mill play in the pretreatment of B4C/Al composite powders? Optimize Your Metal Matrix

- Why are tungsten carbide grinding balls selected for silicon nitride-alumina synthesis? Achieve 99.95% Ceramic Purity

- What role do high-energy ball mills play in MPEA powders? Achieve Nanoscale Precision in Mechanical Alloying