At their core, the difference between a dry oven and an incubator is their fundamental purpose. A laboratory oven is a high-temperature chamber designed for sterilization, drying, and baking, while an incubator is a precisely controlled environment designed to grow and maintain biological samples at lower, life-sustaining temperatures.

The choice between an oven and an incubator is a choice between destruction and cultivation. Ovens use high heat (up to 300°C) to eliminate moisture and microorganisms, whereas incubators use precise, gentle heat (typically ambient to 80°C) and controlled conditions to support life.

The Core Functional Distinction: Heat vs. Environment

The design of each device is optimized for its specific and opposing function. Understanding these differences is critical to preventing failed experiments and damaged equipment.

Temperature Range and Purpose

A laboratory oven is built for high-heat applications. Its typical temperature range is from slightly above ambient to 250°C or 300°C (482°F to 572°F).

This capability makes it ideal for processes that require intense thermal energy, such as dry heat sterilization of glassware, dehydrating samples, or curing materials.

An incubator, by contrast, operates in a much lower and narrower temperature range, often from ambient to 80°C, with some models reaching 100°C.

Its purpose is not to bake or sterilize but to mimic the physiological conditions necessary for biological growth, such as cultivating bacteria, yeast, or mammalian cell cultures.

Precision and Environmental Control

Precision is the defining feature of an incubator. It is engineered for exceptional temperature stability and uniformity (often within ±0.1°C) because even minor fluctuations can stress or kill sensitive cell cultures.

Incubators often control more than just heat. Many models manage humidity to prevent culture media from evaporating and CO2 levels to maintain the proper pH balance required for cell growth.

Ovens have less stringent requirements for temperature uniformity. While they maintain a setpoint, their primary goal is delivering high thermal energy, not the delicate consistency needed for biological work. They offer no control over humidity or atmospheric gas.

Key Applications: When to Use Each Device

Choosing the wrong instrument will, at best, be ineffective and, at worst, completely invalidate your results.

Typical Uses for a Laboratory Oven

An oven is the correct choice for any high-heat, non-biological application.

- Sterilizing metal instruments and glassware

- Drying scientific samples to a constant weight

- Curing polymers or epoxies

- Annealing materials

Typical Uses for a Laboratory Incubator

An incubator is essential for any process involving the maintenance or propagation of living organisms.

- Growing bacterial and yeast cultures on petri dishes

- Cultivating sensitive mammalian cell cultures

- Conducting biochemical or enzymatic assays at specific temperatures

- Studying insect or plant germination

Understanding the Trade-offs and Critical Errors

Using these instruments interchangeably is one of the most common and costly errors in a laboratory setting.

The Danger of Using an Oven as an Incubator

Attempting to grow cultures in a laboratory oven will fail. The temperature control is too imprecise, and temperature spikes will quickly kill your samples.

Furthermore, the dry, often fan-circulated air will rapidly dehydrate your culture media, destroying the growth environment and compromising your experiment.

The Limitations of Using an Incubator as an Oven

An incubator simply cannot get hot enough for proper sterilization. Dry heat sterilization requires sustained temperatures of 160-180°C, far beyond the capacity of any standard incubator.

Attempting to dry samples in an incubator will be slow and inefficient, and you will never achieve the complete moisture removal possible in a proper oven.

Contamination Risks

The warm, humid environment inside an incubator is an ideal breeding ground for contaminating fungi and bacteria. They require regular cleaning and decontamination to ensure experimental integrity.

Ovens, by virtue of their high operating temperatures, are essentially self-sterilizing and pose a much lower risk of cross-contamination.

Making the Right Choice for Your Application

Your intended application is the only factor that matters when choosing between these two instruments.

- If your primary focus is sterilization, drying, or curing: You require the high, stable heat of a laboratory oven.

- If your primary focus is growing or maintaining living cells or organisms: You need the precise, multi-variable environmental control of an incubator.

- If you need to maintain a specific humidity or CO2 level: A specialized incubator is your only option; an oven cannot perform these functions.

Selecting the correct instrument is the first step toward reliable and repeatable scientific outcomes.

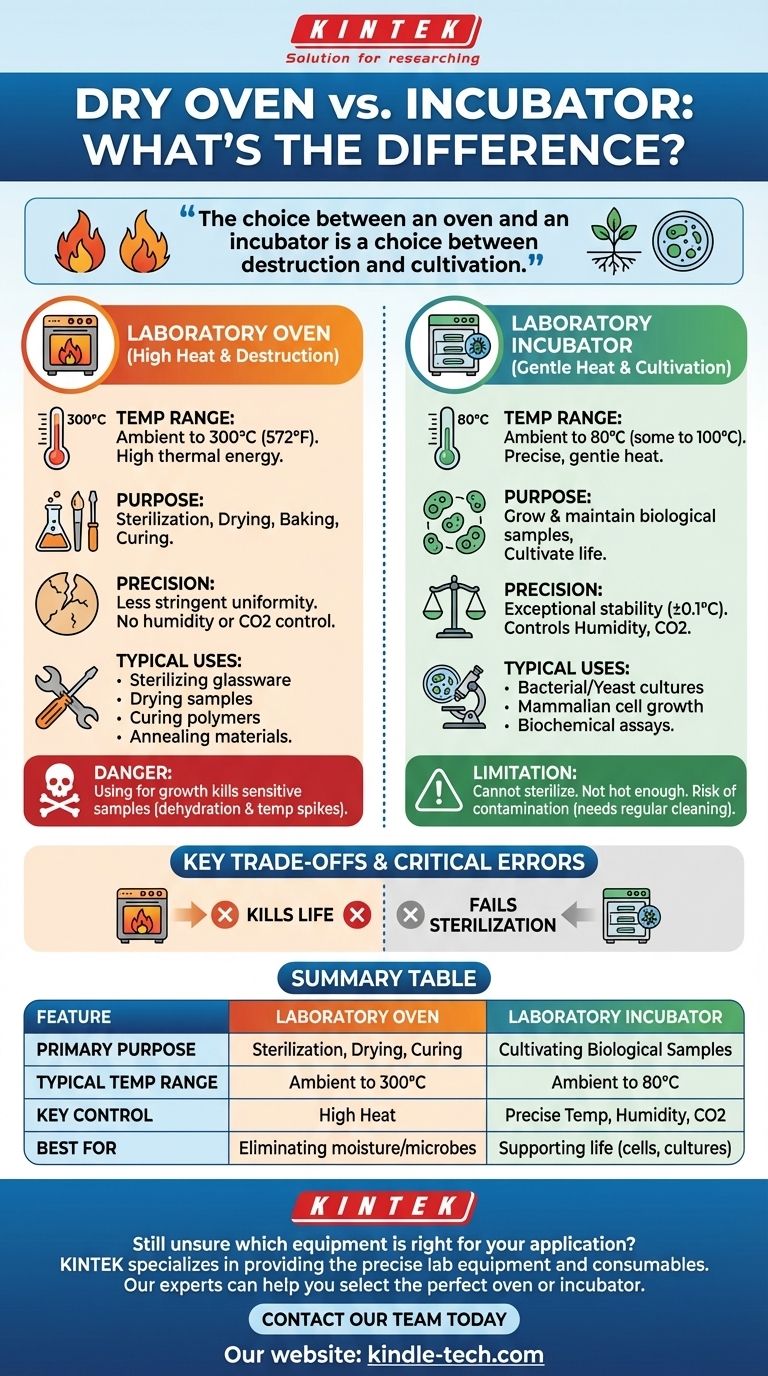

Summary Table:

| Feature | Laboratory Oven | Laboratory Incubator |

|---|---|---|

| Primary Purpose | Sterilization, Drying, Curing | Cultivating Biological Samples |

| Typical Temp Range | Ambient to 300°C | Ambient to 80°C (some to 100°C) |

| Key Control | High Heat | Precise Temperature, Humidity, CO2 |

| Best For | Eliminating moisture/microbes | Supporting life (cells, bacteria, cultures) |

Still unsure which equipment is right for your application? KINTEK specializes in providing the precise lab equipment and consumables your laboratory needs. Our experts can help you select the perfect oven or incubator to ensure reliable and repeatable scientific outcomes. Contact our team today for a personalized consultation and enhance your lab's efficiency.

Visual Guide

Related Products

- Low-Temperature Water-Cooled Touchscreen Vibratory Ultrafine Pulverizer

- 1700℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- Benchtop Laboratory Freeze Dryer for Lab Use

- Laboratory Scientific Electric Heating Blast Drying Oven

People Also Ask

- What is the mechanism of a cryogenic grinder? Master Polymer Powder Preparation for Additive Manufacturing

- Does milling reduce particle size? Achieve Precise Control Over Your Material's Properties

- How does a Vibratory Mill improve niobium recovery efficiency? Optimize Waste Pre-treatment for Maximum Yield

- What is the mechanism of a grinding machine? Achieve Superior Precision and Surface Finishes

- What are the different types of grinding mills? Match the Mechanism to Your Material for Optimal Size Reduction