In material processing, the key difference is one of degree and intent. Grinding is the broad term for reducing the size of a solid by crushing it between surfaces. Pulverizing is a specific, more intense type of grinding that aims to reduce a material to a very fine powder or dust.

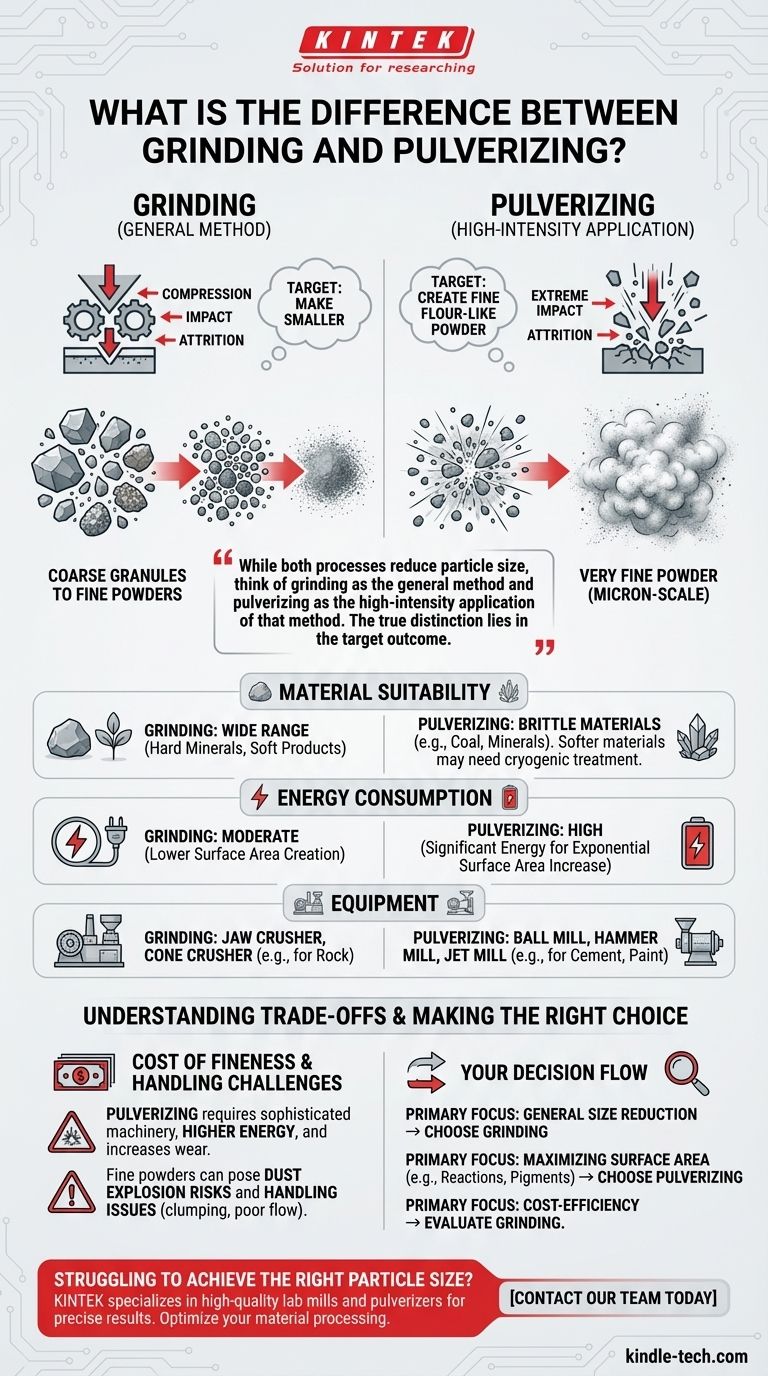

While both processes reduce particle size, think of grinding as the general method and pulverizing as the high-intensity application of that method. The true distinction lies in the target outcome: grinding makes things smaller, while pulverizing aims to create a fine, flour-like powder.

The Mechanics of Size Reduction

To choose the right process, it's essential to understand the underlying forces at work and the specific goal each method is designed to achieve.

The Principle of Grinding

Grinding is a versatile process that encompasses several mechanical actions to break down materials. These actions include compression, impact, and attrition (shearing or rubbing).

The primary goal of grinding is often simply to reduce bulk material into smaller, more manageable pieces or to achieve a specific, but not necessarily ultra-fine, particle size.

The Objective of Pulverizing

Pulverizing is a form of grinding that heavily emphasizes impact and attrition to an extreme degree.

The objective is not just to break particles, but to shatter them repeatedly until they become a fine or ultra-fine powder. This process is about creating a massive increase in the material's surface area.

Differentiating by Outcome and Application

The practical differences between these two processes become clear when you look at the final product, the materials used, and the energy required.

Final Particle Size

This is the most critical distinction. Grinding can produce a wide range of particle sizes, from coarse granules (like crushed rock) to finer powders.

Pulverizing, by definition, targets the very fine end of the spectrum. The output is consistently a powder with particles often measured in microns, resembling flour or dust.

Material Suitability

Grinding is a robust method suitable for a vast array of materials, from hard minerals to softer agricultural products.

Pulverizing is most effective on brittle materials that shatter easily upon impact, such as coal, minerals, or certain chemicals. Softer or more ductile materials can be difficult to pulverize and may require cryogenic grinding (freezing) to induce brittleness.

Energy Consumption

Reducing a particle's size creates new surface area, a process that requires a significant amount of energy.

Because pulverizing creates exponentially more surface area to achieve its fine particle size, it is a much more energy-intensive process than coarse or medium grinding.

Understanding the Trade-offs

Choosing a size reduction method is not just about the final particle size; it involves balancing cost, efficiency, and material handling challenges.

The Cost of Fineness

Achieving a fine powder through pulverization comes at a cost. The process demands more sophisticated machinery, higher energy consumption, and results in greater wear and tear on the equipment.

The Challenge of Material Handling

Extremely fine powders created by pulverizing can be difficult to manage. They can pose a dust explosion risk, may clump together due to electrostatic forces, and can have poor flow characteristics, complicating storage and transport.

Choosing the Right Equipment

The machinery reflects the process. A jaw crusher or cone crusher performs coarse grinding on rock. In contrast, a ball mill, hammer mill, or jet mill is required to pulverize minerals into a fine powder for use in products like cement or paint.

Making the Right Choice for Your Process

Your decision should be driven by the specific requirements of your final product.

- If your primary focus is general size reduction: You are likely looking for a grinding process, where the goal is simply to make particles smaller for easier handling or subsequent processing.

- If your primary focus is maximizing surface area: You need to pulverize your material, which is essential for applications like rapid chemical reactions, pigment manufacturing, or producing pharmaceuticals.

- If your primary focus is cost-efficiency: Carefully evaluate if the coarser particles from standard grinding are sufficient for your needs, as pulverizing will significantly increase energy and maintenance costs.

Ultimately, selecting the correct method depends entirely on defining the required final particle size for your material and application.

Summary Table:

| Aspect | Grinding | Pulverizing |

|---|---|---|

| Primary Goal | General size reduction | Create a fine or ultra-fine powder |

| Final Particle Size | Coarse granules to fine powders | Very fine powder, often micron-scale |

| Key Mechanism | Compression, Impact, Attrition | Extreme Impact and Attrition |

| Energy Consumption | Moderate | High |

| Ideal Materials | Wide range (hard minerals to soft products) | Brittle materials (e.g., coal, minerals) |

Struggling to achieve the right particle size for your research or production? The efficiency of your process depends on using the correct size reduction method. KINTEK specializes in providing high-quality lab mills and pulverizers designed for a vast range of materials and applications. Our experts can help you select the ideal equipment to ensure precise results, maximize your lab's efficiency, and control costs.

Let us help you optimize your material processing. Contact our team today for a personalized consultation!

Visual Guide

Related Products

- Laboratory High Throughput Tissue Grinding Mill Grinder

- Laboratory Jar Ball Mill with Alumina Zirconia Grinding Jar and Balls

- Laboratory Disc Cup Vibratory Mill for Sample Grinding

- Laboratory Hybrid Tissue Grinding Mill

- Low-Temperature Water-Cooled Touchscreen Vibratory Ultrafine Pulverizer

People Also Ask

- Why is the use of zirconia grinding balls necessary? Ensure High Purity and Efficiency in Ceramic Milling

- Why is it important to grind the sample finely and pack it tightly before performing a melting point determination? Ensure Accurate and Sharp Melting Points

- What role does ball milling play in Ni-Al2O3-TiO2 composite powders? Master Mechanical Activation & Homogeneity

- What dual processes can jet milling accomplish? Master Micronization and Classification in One Step

- What are the ball sizes in ball mill? Optimize Your Grinding Efficiency & Cost

- Why use grinding for SPS samples before XRD? Master Sample Prep for Pure Phase Analysis

- What is the role of a ball mill in preparing the suspension for EPD of spinel coatings? Ensure Density and Uniformity

- What is the primary purpose of using grinding equipment for Tetradenia riparia extracts? Maximize Leaching Efficiency