To pulverize an object means to reduce it to a fine powder or dust, a task accomplished using tools that apply forces like impact, compression, and attrition. The right tool depends entirely on the material's properties and the desired final particle size, ranging from simple hand tools like a mortar and pestle to powerful industrial machinery like jaw crushers and ball mills.

Choosing a pulverizing tool is not about the tool itself, but about understanding your material. The key is to match the tool's mechanical action—be it crushing, grinding, or milling—to the object's hardness, brittleness, and the specific outcome you need to achieve.

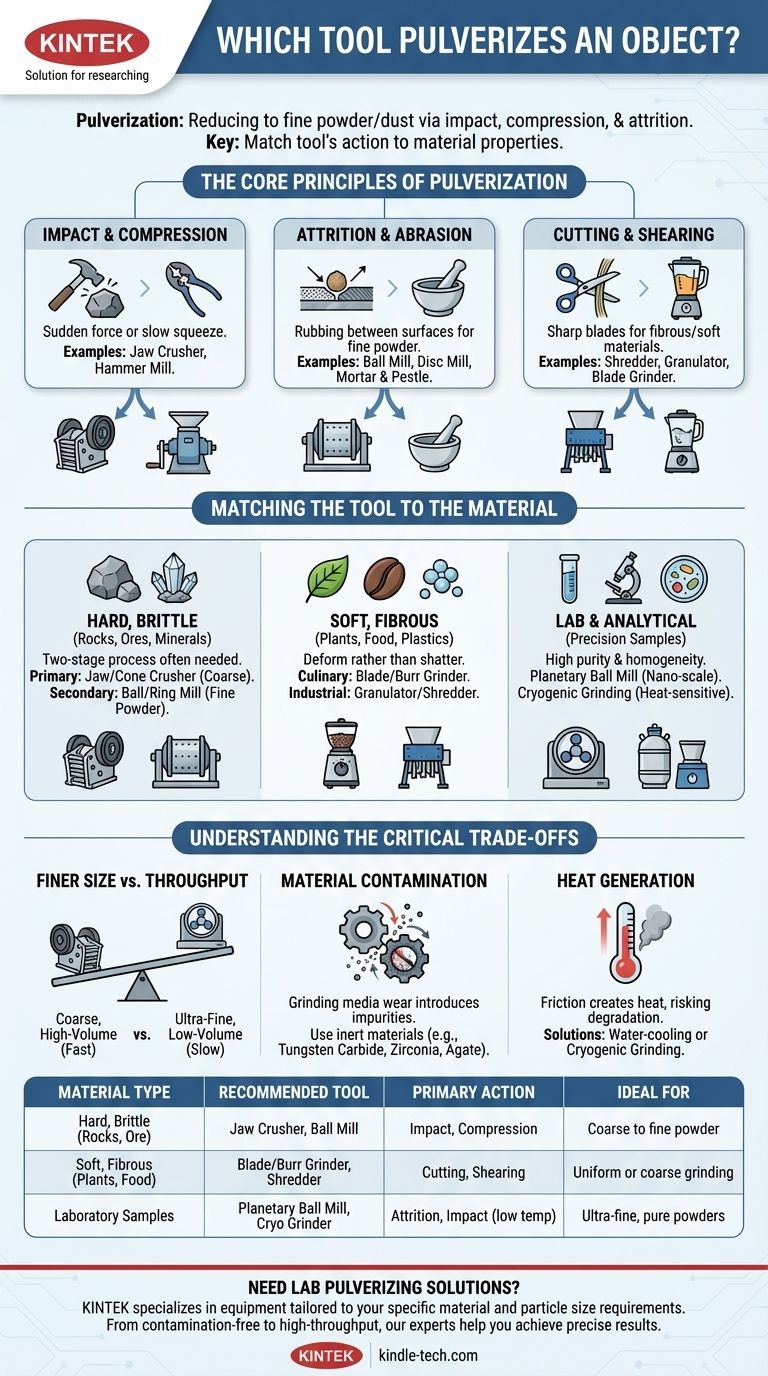

The Core Principles of Pulverization

Pulverization is fundamentally about mechanical size reduction. Different tools achieve this using distinct physical forces, and understanding these principles is the first step in selecting the right equipment.

Impact and Compression

This method involves applying a sudden, high-force blow or a slow, powerful squeeze. It is extremely effective for breaking down hard, brittle materials.

Think of a nutcracker. It uses compression to break the shell. Industrial machines like jaw crushers use a similar principle on a massive scale for rocks and ore. Hammer mills use high-speed rotating hammers to shatter material through impact.

Attrition and Abrasion

This method reduces particle size by rubbing material between two hard surfaces. It excels at producing very fine, uniform powders from materials that have already been partially broken down.

A mortar and pestle is the classic example, using pressure and friction. More advanced tools like disc mills grind material between two grooved plates, while ball mills tumble the material with heavy spheres (e.g., steel or ceramic) in a rotating drum to create fine powders through a combination of impact and attrition.

Cutting and Shearing

While not always leading to a true powder, cutting and shearing are vital for size reduction of softer, fibrous, or pliable materials.

A kitchen blender uses sharp, high-speed blades to chop and shear food items. Industrial shredders or granulators use a similar principle to process plastics, wood, or waste materials as a preliminary step before finer grinding.

Matching the Tool to the Material

The nature of your object dictates the tool. A tool designed for rock will perform poorly on a soft plant material, and vice versa.

For Hard, Brittle Materials (Rocks, Minerals, Ores)

Your primary challenge is overcoming high compressive strength. This often requires a two-stage process.

First, a jaw crusher or cone crusher performs primary size reduction, breaking large boulders or chunks into more manageable gravel-sized pieces.

For the second stage, a ring mill, disc pulverizer, or ball mill is used to grind the gravel into a fine, consistent powder suitable for laboratory analysis or industrial processing.

For Softer or Fibrous Materials (Plants, Food, Plastics)

These materials tend to deform rather than shatter. Tools that cut or tear are more effective.

For culinary use, a blade grinder (like in a coffee grinder or blender) works for a coarse result, while a burr grinder provides a much more uniform, fine powder for spices and grains. A mortar and pestle offers maximum control for small batches.

For industrial-scale processing of plastics or organic waste, a granulator or shredder is the first step, followed by a hammer mill if a finer output is needed.

For Laboratory and Analytical Sample Prep

Precision and purity are paramount in a lab setting. The goal is a homogenous sample that won't damage analytical instruments.

A planetary ball mill is a high-energy version of a standard ball mill, capable of rapidly pulverizing very hard materials to nano-scale sizes.

For heat-sensitive or tough, elastic samples (like polymers), cryogenic grinding is used. The material is frozen with liquid nitrogen to make it brittle, then shattered in a specialized mill. This preserves volatile compounds and prevents the sample from melting.

Understanding the Critical Trade-offs

No single tool is perfect. Selecting one involves balancing performance, cost, and the quality of the final product.

Final Particle Size vs. Throughput

There is an inverse relationship between how fine the powder is and how quickly you can produce it.

High-throughput machines like jaw crushers produce coarse material quickly. Mills that produce ultra-fine powders, like planetary or attrition mills, typically process smaller batch sizes and take more time.

Material Contamination

The grinding process itself can introduce impurities. The surfaces of the mill or the grinding media (e.g., steel balls) can wear away and mix with your sample.

This is a major concern in geological or chemical analysis. To prevent this, grinding elements are often made from extremely hard, inert materials like tungsten carbide, zirconia, or agate.

Heat Generation

Friction and impact create significant heat. This can be detrimental, causing chemical degradation, loss of volatile oils (as in spices), or even melting the sample.

If your material is heat-sensitive, you must either choose a slower grinding method, use a water-cooled mill, or opt for cryogenic grinding as the definitive solution.

Making the Right Choice for Your Goal

To select the correct pulverizing tool, start by defining your material and your desired outcome.

- If your primary focus is coarse, high-volume size reduction of hard materials: Use a jaw crusher, cone crusher, or impact mill.

- If your primary focus is creating a very fine, pure powder for laboratory analysis: Use a disc mill, ball mill, or a cryogenic grinder with appropriate contamination-free components.

- If your primary focus is processing food, spices, or grains at home: A burr grinder will give you uniform results, while a mortar and pestle offers excellent control for small quantities.

- If your primary focus is general-purpose size reduction of mixed or soft materials: A high-speed blender or a more robust shredder is your most effective starting point.

Ultimately, understanding the properties of the object you wish to pulverize is the most critical step in selecting the right tool for the job.

Summary Table:

| Material Type | Recommended Tool | Primary Action | Ideal For |

|---|---|---|---|

| Hard, Brittle (Rocks, Ore) | Jaw Crusher, Ball Mill | Impact, Compression | Coarse to fine powder |

| Soft, Fibrous (Plants, Food) | Blade/Burr Grinder, Shredder | Cutting, Shearing | Uniform or coarse grinding |

| Laboratory Samples | Planetary Ball Mill, Cryogenic Grinder | Attrition, Impact (at low temps) | Ultra-fine, pure powders |

| General Purpose | Hammer Mill, Mortar & Pestle | Impact, Attrition | Versatile size reduction |

Struggling to find the right pulverizing equipment for your lab? KINTEK specializes in lab equipment and consumables, providing solutions tailored to your specific material and particle size requirements. Whether you need contamination-free grinding for sensitive analysis or high-throughput crushing for industrial samples, our experts will help you select the perfect tool. Contact us today to optimize your pulverization process and achieve precise, reliable results!

Visual Guide

Related Products

- Laboratory Jar Ball Mill with Alumina Zirconia Grinding Jar and Balls

- Liquid Nitrogen Cryogenic Grinder Mill Cryomill with Screw Feeder

- lab cryogenic grinding use liquid-nitrogen for pulverizing plastic raw materials and heat sensitive materials

- Low-Temperature Water-Cooled Touchscreen Vibratory Ultrafine Pulverizer

- Laboratory High Throughput Tissue Grinding Mill Grinder

People Also Ask

- What are the requirements for ball milling jars in LiMOCl4 synthesis? Ensure Safety and Purity in High-Pressure Reactions

- What is the speed range of a ball mill? Find Your Optimal Grinding Efficiency

- What is the primary function of a planetary ball mill in ODS steel prep? Achieving Nanoscale Mechanical Alloying

- What is the role of a planetary ball mill in the solid-state synthesis of NASICON-type solid electrolytes? Unlock Purity

- What is the function of a planetary ball mill in the synthesis of (Cu–10Zn)-Al2O3 nanocomposites? High-Energy Alloying