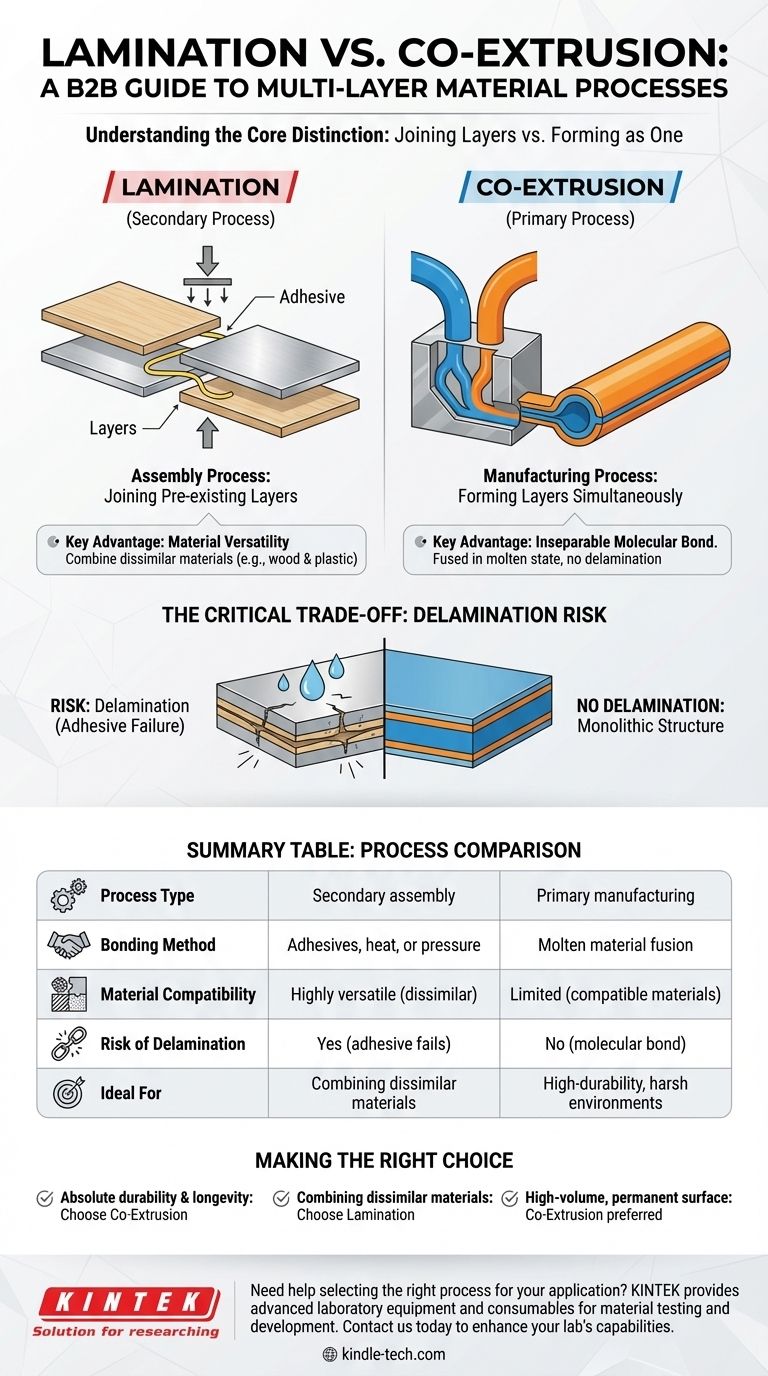

At its core, the difference is simple. Lamination is a secondary process that joins pre-existing, separate layers of material together using adhesives, heat, or pressure. In contrast, co-extrusion is a primary manufacturing process that forms a single, integrated object with multiple layers simultaneously from molten materials.

The choice between lamination and co-extrusion hinges on a critical trade-off: lamination offers the versatility to combine vastly different materials, while co-extrusion creates a superior, inseparable molecular bond that makes delamination impossible.

The Core Concept: Layering for Performance

Why Create Multi-Layer Materials?

Engineers and designers create multi-layer materials to achieve a combination of properties that a single material cannot provide.

This approach allows a product to have, for example, a strong, inexpensive core material with a separate surface layer that provides color, UV resistance, or a specific texture.

A Shared Goal, Different Paths

Both lamination and co-extrusion are used to achieve this goal of imparting different properties to a material's surface compared to its core. The fundamental difference lies in how and when those layers are brought together.

Lamination: Joining Separate Worlds

How Lamination Works

Lamination is an assembly process. It begins with two or more fully formed, independent sheets of material.

These sheets are then bonded together. This bonding is typically achieved using a layer of adhesive, combined with heat and high pressure to create a permanent join.

Key Advantage: Material Versatility

The primary strength of lamination is its ability to combine materials that are fundamentally dissimilar. You can laminate a thin plastic film onto a wood panel, a metal foil onto paper, or a fabric layer onto a rigid polymer sheet—combinations that are impossible with co-extrusion.

Co-Extrusion: A Single, Unified Structure

How Co-Extrusion Works

Co-extrusion is a single, continuous manufacturing process. Multiple extruders melt different plastic resins, which are then fed into a single extrusion die.

Inside the die, these separate molten streams are combined to form a single, multi-layered profile. The materials exit the die and cool as one inseparable piece.

Key Advantage: The Inseparable Bond

Because the different materials are fused together in a molten state, they form a true molecular bond. This creates a monolithic structure where the layers are permanently integrated.

This complete fusion is the defining advantage of a co-extruded product.

Understanding the Key Trade-off: Delamination

The Inherent Risk of Lamination

The weak point of any laminated product is the bond line between its layers. Delamination occurs when these layers begin to separate.

This separation can be caused by moisture, temperature fluctuations, or physical stress. For many applications, delamination is the primary mode of product failure.

The Durability of a Co-Extruded Bond

With a co-extruded part, delamination cannot occur. There is no adhesive layer to fail. The layers are not simply stuck together; they were formed as one.

This makes co-extrusion the superior choice for products that demand long-term durability and will be exposed to harsh environmental conditions.

The Limitation of Material Compatibility

Co-extrusion does have a limitation: the materials being combined must have compatible processing characteristics. Their melt temperatures and flow rates must be similar enough to be processed through the same die simultaneously.

Making the Right Choice for Your Application

The ideal process depends entirely on your product's performance requirements and material needs.

- If your primary focus is absolute durability and longevity: Co-extrusion is the superior choice because its integrated bond completely eliminates the risk of delamination.

- If your primary focus is combining highly dissimilar materials: Lamination provides the unique flexibility to bond materials like wood, metal, and plastic that cannot be processed together.

- If your primary focus is cost-effective surface finishing: Both can be viable, but co-extrusion is often preferred for high-volume applications where a permanent surface is critical.

Understanding this fundamental distinction between joining existing layers and forming them as one empowers you to select the right process for a superior and reliable final product.

Summary Table:

| Feature | Lamination | Co-extrusion |

|---|---|---|

| Process Type | Secondary assembly process | Primary manufacturing process |

| Bonding Method | Adhesives, heat, or pressure | Molten material fusion |

| Material Compatibility | Highly versatile (dissimilar materials) | Limited (requires compatible materials) |

| Risk of Delamination | Yes (adhesive layer can fail) | No (molecular bond) |

| Ideal For | Combining dissimilar materials | High-durability, harsh environments |

Need help selecting the right process for your multi-layer material application? KINTEK specializes in providing advanced laboratory equipment and consumables to support your material testing and development needs. Whether you're working with laminated composites or co-extruded polymers, our solutions help ensure optimal performance and reliability. Contact us today to discuss how we can enhance your lab's capabilities and achieve superior results for your specific material challenges!

Visual Guide

Related Products

- Engineering Advanced Fine Alumina Al2O3 Ceramic Rod Insulated for Industrial Applications

- Advanced Engineering Fine Ceramics Alumina Ceramic Saggar for Fine Corundum

- Engineering Advanced Fine Ceramics Head Tweezers with Pointed Elbow Zirconia Ceramic Tip

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Multi Heating Zones CVD Tube Furnace Machine Chemical Vapor Deposition Chamber System Equipment

People Also Ask

- What functions do high-purity alumina support rods serve in sCO2 experiments? Ensure High-Temp Material Integrity

- What is the maximum temperature for alumina tube? Unlock Its Full Potential with High Purity

- What is the maximum operating temperature of alumina? The Critical Role of Purity and Form

- Why are ceramics more resistant to corrosion? Unlock the Secret to Unmatched Chemical Stability

- Why is an alumina insulation disk required in a CCPD reactor? Enhance Coating Quality with Floating Potential