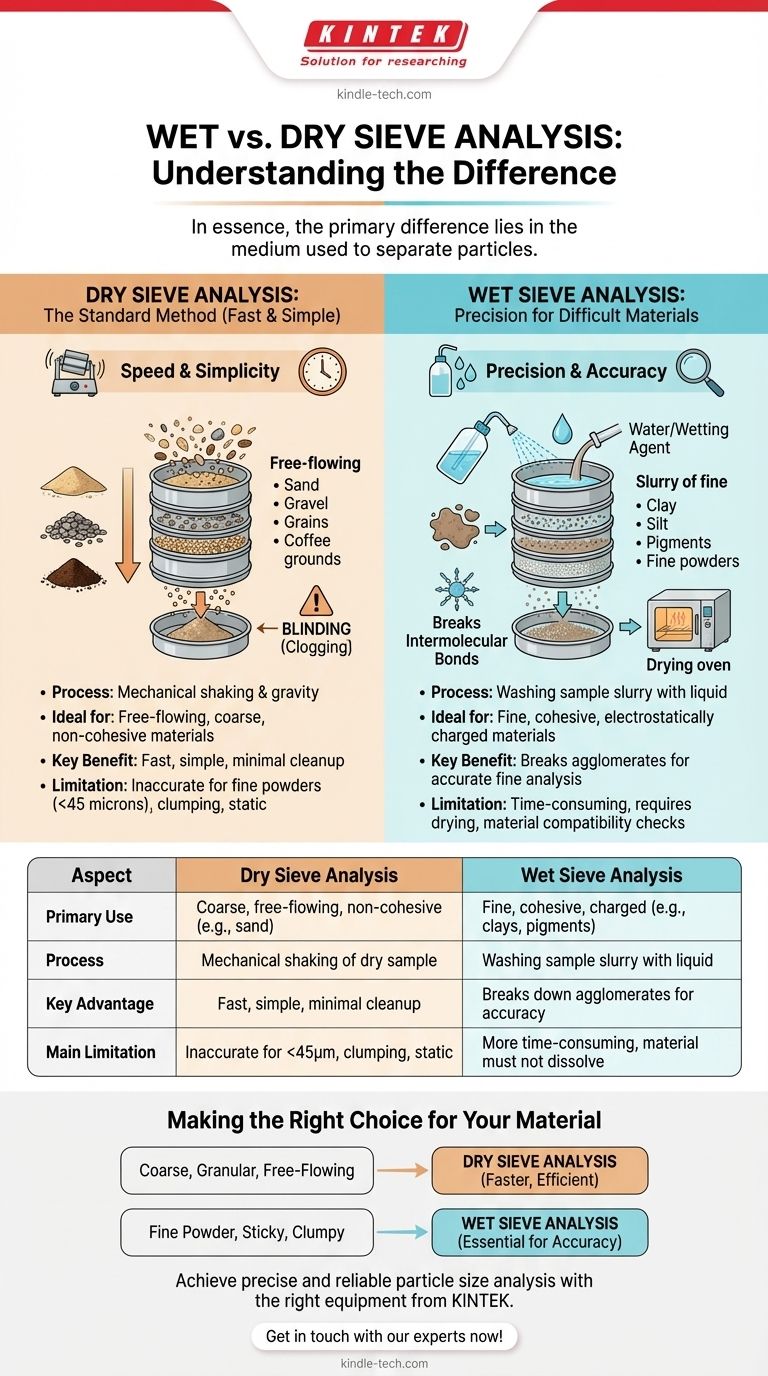

In essence, the primary difference lies in the medium used to separate particles. Dry sieve analysis relies on mechanical shaking and gravity to pass particles through a stack of sieves, while wet sieve analysis introduces a liquid—typically water—to wash the material through the sieves, breaking down agglomerates and eliminating electrostatic forces.

The choice between wet and dry sieving is not about which method is universally "better," but which is appropriate for your specific material. The decision hinges on whether the particles are fine, cohesive, or prone to static charge, which would prevent an accurate analysis with the simpler dry method.

The Standard Method: Dry Sieve Analysis

Dry sieving is the most common method for particle size analysis due to its simplicity and speed. It serves as the default approach when material characteristics allow for it.

How It Works

A sample of the material is placed on the top sieve of a stacked column, with mesh sizes decreasing from top to bottom. The entire stack is then agitated by a mechanical shaker, allowing particles to fall through the apertures until they are retained by a sieve with a mesh too fine for them to pass.

When It's Most Effective

Dry sieving is ideal for materials that are free-flowing, coarse, and non-cohesive. Think of materials like dry sand, gravel, coffee grounds, grains, or plastic pellets. These particles do not tend to stick to each other or to the sieve mesh.

The Primary Limitation

The method's effectiveness plummets when dealing with fine powders (typically smaller than 45 microns), materials that clump together due to moisture (agglomerate), or particles influenced by static electricity. These forces cause particles to bind together or to the sieve mesh, preventing them from passing through apertures they would otherwise fit through, a phenomenon known as blinding. This leads to inaccurate and unreliable results.

When Precision Is Paramount: Wet Sieve Analysis

Wet sieving is a more specialized technique designed to overcome the limitations of the dry method. It ensures that each particle is individually assessed by the sieve mesh.

The Underlying Principle

By introducing a liquid (usually water with a wetting agent), wet sieving breaks the intermolecular bonds and washes away static charges that cause particles to clump. Think of it like trying to separate muddy gravel—hosing it down is far more effective than just shaking it.

The Critical Advantage

This method is the definitive choice for materials that are fine, cohesive, or electrostatically charged. It is essential for accurately sizing materials like clays, silts, powdered pigments, and many pharmaceutical or chemical powders where agglomeration would otherwise make dry sieving impossible.

A More Involved Process

The process typically involves creating a slurry of the sample and pouring it onto the top sieve. The liquid helps transport the fine particles through the sieve stack. The material retained on each sieve is then dried in an oven and weighed to determine the particle size distribution.

Understanding the Trade-offs

Choosing a method requires a clear understanding of the balance between accuracy, effort, and material compatibility.

Accuracy vs. Material Type

For coarse, free-flowing materials, dry sieving is perfectly accurate and sufficient. For fine or sticky materials, wet sieving is non-negotiable for achieving an accurate result. Attempting to dry sieve an unsuitable material will yield meaningless data.

Time and Complexity

Dry sieving is significantly faster and simpler. The process is straightforward: weigh, shake, and re-weigh. Wet sieving adds multiple steps, including sample preparation, washing, and a crucial, often lengthy, drying step before the final weighing can occur.

Equipment and Cleanup

Wet sieving requires a water source, a drainage system, and potentially specialized equipment to handle the liquid. It also necessitates a more thorough cleanup. The retained samples must be completely dried in an oven, adding another equipment requirement.

Material Compatibility

A critical prerequisite for wet sieving is that the material must not dissolve, react, or swell in the chosen liquid. For water-soluble materials, a different, non-reactive liquid (like an alcohol) must be used, which can introduce additional complexity and cost.

Making the Right Choice for Your Material

Your material's inherent properties should be the sole determinant of your testing method.

- If your material is coarse, granular, and free-flowing (e.g., sand, grain, plastic pellets): Dry sieving is the faster, more efficient, and fully appropriate choice.

- If your material is a fine powder, clay, or feels sticky/clumpy to the touch (e.g., pigments, cohesive soils, certain APIs): Wet sieving is essential for breaking down agglomerates and achieving an accurate result.

- If you are unsure or the material has a wide distribution of sizes including very fine particles: A preliminary wet sieve analysis is the most reliable way to establish a trustworthy baseline.

Ultimately, selecting the correct sieving method is the first and most critical step toward reliable particle size data.

Summary Table:

| Aspect | Dry Sieve Analysis | Wet Sieve Analysis |

|---|---|---|

| Primary Use | Coarse, free-flowing, non-cohesive materials (e.g., sand, grains) | Fine, cohesive, or electrostatically charged materials (e.g., clays, pigments) |

| Process | Mechanical shaking of a dry sample through a stack of sieves | Washing a sample slurry through sieves using a liquid (e.g., water) |

| Key Advantage | Fast, simple, and requires minimal cleanup | Breaks down agglomerates for accurate analysis of fine/sticky powders |

| Main Limitation | Inaccurate for particles <45 microns or materials prone to clumping/static | More time-consuming; material must not dissolve or react with the liquid |

Achieve precise and reliable particle size analysis with the right equipment from KINTEK.

Whether your materials require the simplicity of dry sieving or the precision of wet sieving, KINTEK specializes in high-quality lab sieves, shakers, and accessories to meet your specific laboratory needs. Our experts can help you select the perfect setup for accurate results with your sands, clays, powders, or chemicals.

Contact us today to discuss your application and ensure your lab has the optimal sieving solution.

Get in touch with our experts now!

Visual Guide

Related Products

- Laboratory Test Sieves and Sieving Machines

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Laboratory Single Horizontal Jar Mill

People Also Ask

- What are the 4 methods of determining particle size? Choose the Right Technique for Your Lab

- What were possible sources of error in sieve analysis? Avoid These Common Pitfalls for Accurate Results

- How sieve analysis is conducted in the Laboratory? A Step-by-Step Guide to Accurate Particle Sizing

- What is the importance of sieving in chemistry? Master Particle Size for Precise Control

- What is ASTM standard sieve? Ensure Precision in Particle Size Analysis

- What are the disadvantages of sieve analysis method of particle size analysis? Key Limitations to Consider

- How do you calculate the sieve test? Master Particle Size Distribution for Quality Control

- Why use a 500-mesh sieve for wool biochar? Ensure uniform dispersion and flawless coatings.