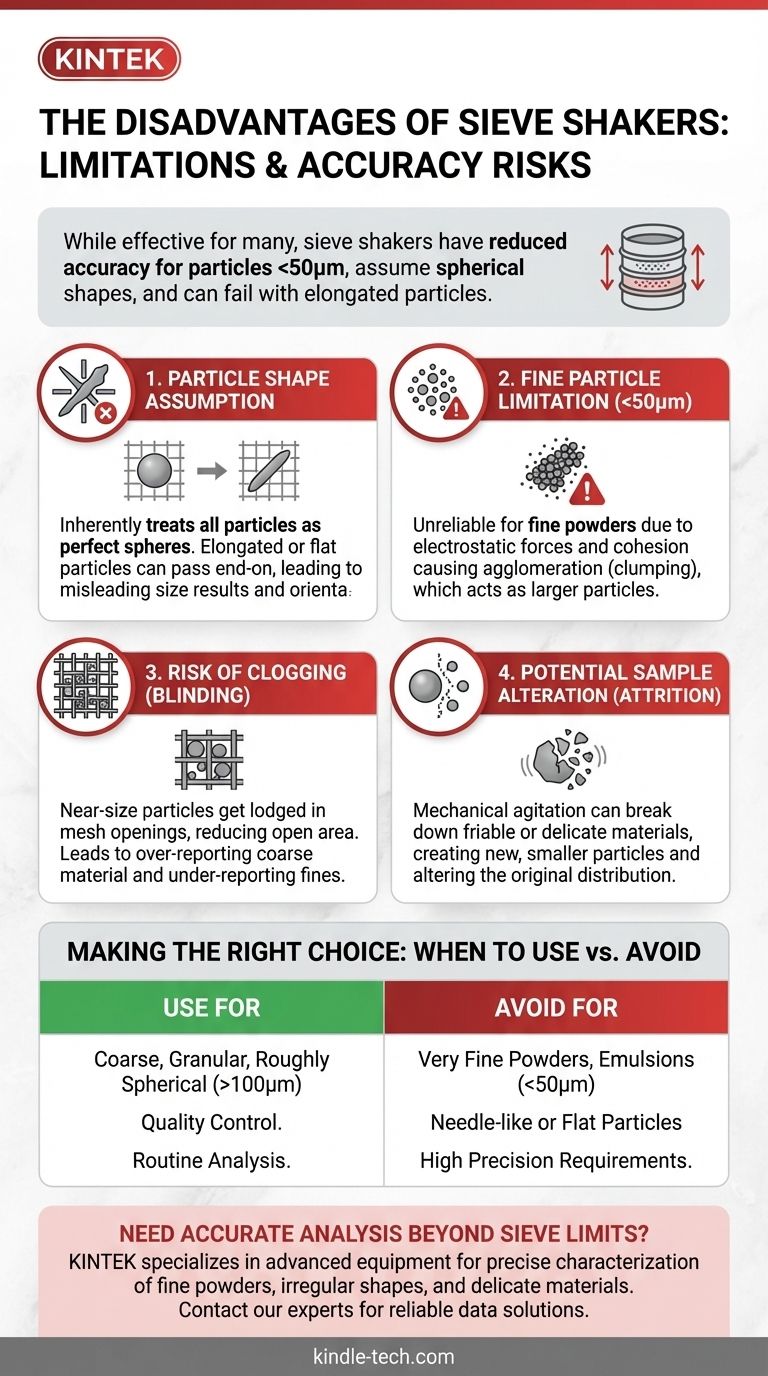

While highly effective for many applications, the primary disadvantages of a sieve shaker are its reduced accuracy for particles smaller than approximately 50 microns (µm), its inherent assumption that all particles are perfect spheres, and its potential to deliver unreliable results for elongated or flat particles. These limitations can lead to significant measurement errors if the instrument is used outside of its ideal operational parameters.

A sieve shaker is a cost-effective and simple tool for particle size analysis, but its accuracy fundamentally depends on two conditions that are not always met: that particles are roughly spherical and are not fine enough to cause electrostatic or clogging issues.

The Principle: How a Sieve Shaker Works

To understand the disadvantages, we must first understand the core mechanism. A sieve shaker is a device that automates the process of passing material through a stack of test sieves with progressively smaller mesh openings.

The Basic Mechanism

A sieve shaker imparts a specific motion—often a 3-D throwing action—to a stack of sieves. This agitation encourages particles to move and find an opening they can pass through.

Larger particles are retained on the upper sieves with larger openings, while smaller particles continue downward until they are retained by a sieve with mesh too fine for them to pass.

What It Measures (and What It Assumes)

After the shaking cycle, the material retained on each sieve is weighed. This provides a mass-based distribution of particle sizes within the sample.

Crucially, this entire method is based on a geometric assumption: a particle will pass through a square opening if its second-largest dimension is smaller than the mesh size. This inherently treats all complex, 3D particles as simple spheres.

Key Disadvantages in Detail

The limitations of a sieve shaker stem directly from its simple mechanical principle. For many materials, these disadvantages can outweigh the benefits of speed and low cost.

The Particle Shape Assumption

The most significant disadvantage is the inability to account for irregular particle shapes. Elongated, needle-like, or flat, flaky particles can produce misleading results.

For example, a long, thin particle might pass through a sieve mesh end-on, registering it as a "small" particle. However, if it had oriented flat against the mesh, it would have been retained. This orientation bias skews the mass distribution and produces inaccurate, non-reproducible data.

The Fine Particle Limitation

Sieve analysis becomes unreliable for particles finer than about 50 µm (or around 300 mesh). Some sources even cite a practical limit closer to 100 µm.

Below this size, forces like static electricity and cohesion cause fine particles to agglomerate, or clump together. These clumps behave as larger particles, preventing them from passing through the appropriate mesh and invalidating the results. Wet sieving can help, but it introduces its own complexities.

Risk of Inaccurate Results from Clogging

Fine or near-size particles can become lodged in the openings of the wire mesh, a phenomenon known as blinding or clogging.

This blockage effectively reduces the open area of the sieve, preventing other particles from passing through. If not addressed, clogging leads to an over-reporting of coarse material and an under-reporting of fine material.

Potential for Sample Alteration

The mechanical agitation of a sieve shaker, while necessary for separation, can damage friable or delicate materials.

The constant motion can cause particle attrition, breaking down larger particles into smaller ones during the analysis. This size reduction error means you are no longer measuring the original sample's particle distribution, but rather one that was created during the testing process itself.

Making the Right Choice for Your Goal

A sieve shaker remains a valuable tool when used correctly. The decision to use one depends entirely on your material type and the level of analytical precision you require.

- If your primary focus is on coarse, granular, or roughly spherical materials (>100 µm): The sieve shaker is an efficient, cost-effective, and reliable choice for quality control and routine analysis.

- If your primary focus is on very fine powders, emulsions, or materials <50 µm: You must consider alternative methods like laser diffraction or dynamic light scattering for accurate results.

- If your primary focus is on analyzing needle-like or flat particles where shape is a critical factor: Sieve analysis will likely produce misleading data, and you should use image analysis techniques instead.

Understanding these limitations empowers you to select the right tool for your specific analytical challenge.

Summary Table:

| Disadvantage | Key Impact |

|---|---|

| Assumes Spherical Particles | Inaccurate results for elongated or flat particles due to orientation bias. |

| Limited for Fine Particles (<50µm) | Unreliable data due to agglomeration from static electricity and cohesion. |

| Risk of Sieve Clogging (Blinding) | Blocked mesh openings lead to over-reporting of coarse material. |

| Potential for Particle Attrition | Mechanical agitation can break down friable samples, altering the true size distribution. |

Need accurate particle size analysis beyond the limits of a sieve shaker? KINTEK specializes in advanced lab equipment and consumables for precise material characterization. Whether you're working with fine powders, irregular shapes, or delicate materials, we provide solutions that deliver reliable, reproducible data. Contact our experts today to find the right analytical tool for your laboratory's specific needs!

Visual Guide

Related Products

- Laboratory Test Sieves and Vibratory Sieve Shaker Machine

- Laboratory Vibratory Sieve Shaker Machine for Dry and Wet Three-Dimensional Sieving

- Three-dimensional electromagnetic sieving instrument

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Laboratory Multifunctional Small Speed-Adjustable Horizontal Mechanical Shaker for Lab

People Also Ask

- What function does a sieving system perform during HPS powder pretreatment? Ensure Uniform Particle Size Distribution

- Why is powder classification using standard sieves essential for SHS reactions? Unlock Superior Nitriding Results

- Why is a standardized sieving system necessary for elephant grass research? Ensure Reliable Sample Consistency

- How do high-precision sieving systems benefit zeolite preparation? Maximize Adsorption for Wastewater Treatment

- Why is a precision vibratory sieving system important for Pt/Pd alloy analysis? Ensure Data Integrity & XRD Accuracy