The primary disadvantage of the sieve shaker method is its declining accuracy and reliability when analyzing materials that are either very fine or not perfectly spherical. The technique's physical nature means it mischaracterizes elongated and flat particles, struggles with powders finer than 100 mesh (approx. 150 µm), and is generally unsuitable for anything smaller than 50 µm.

While a sieve shaker offers unmatched simplicity and speed for particle sizing, its accuracy fundamentally depends on the material's physical properties. The method's reliance on mechanical sorting means it can produce misleading results when particles deviate from an ideal spherical shape or are fine enough to be affected by forces like static and cohesion.

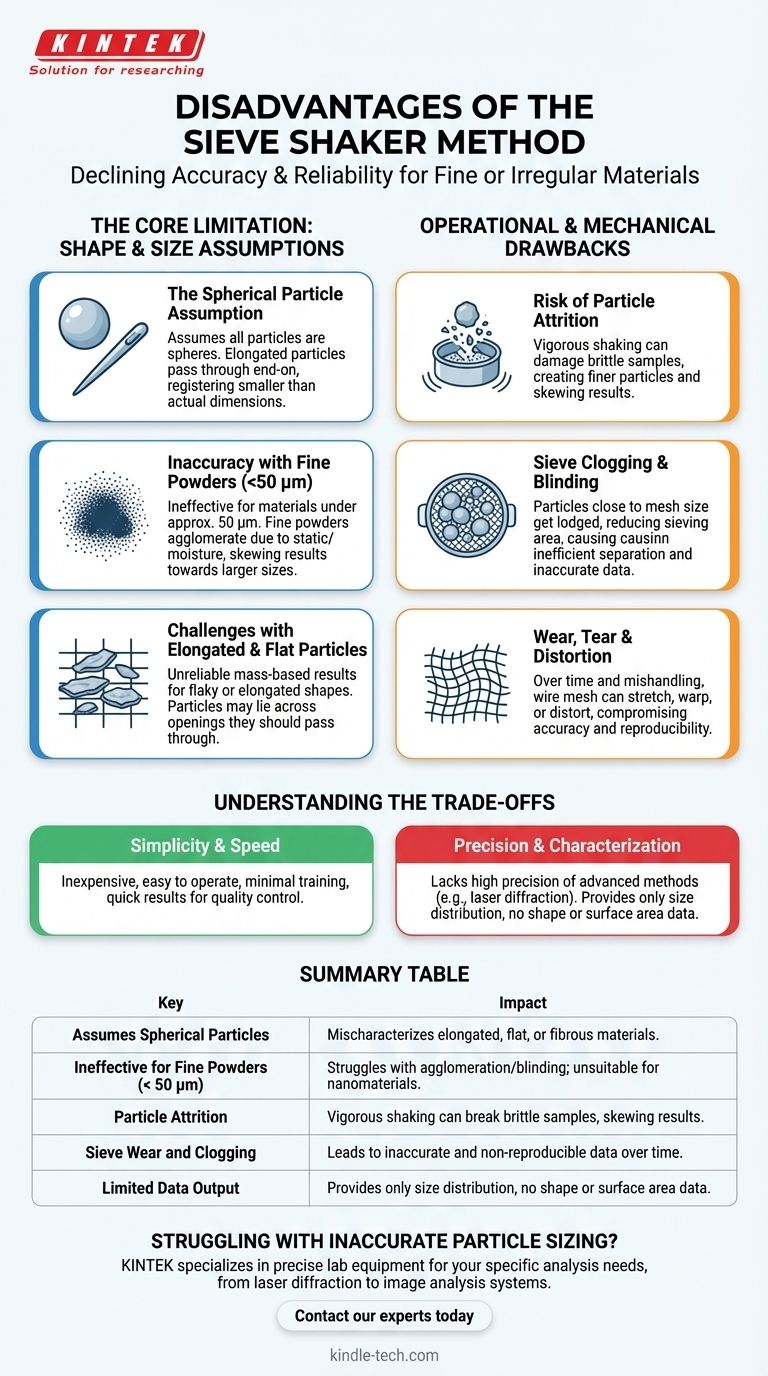

The Core Limitation: Shape and Size Assumptions

A sieve shaker operates on a simple principle: particles pass through openings of a specific size. This simplicity is also the source of its greatest weaknesses.

The Spherical Particle Assumption

The method inherently assumes that all particles are spheres. The analysis reports a size based on the diameter of a sphere that would pass through the same sieve aperture.

This becomes a significant problem with non-spherical particles. An elongated, needle-like particle can pass through a mesh end-on, registering a size based on its smallest dimension, not its true length or volume.

Inaccuracy with Fine Powders

As particle size decreases, a sieve shaker's effectiveness plummets. This is especially true for materials smaller than about 50 µm.

Fine powders tend to agglomerate due to electrostatic forces and moisture, forming clumps that are too large to pass through the correct sieve. This results in an inaccurate distribution skewed towards larger particle sizes.

Challenges with Elongated and Flat Particles

For materials containing flat, flaky, or elongated particles, the mass-based results are often unreliable.

These shapes do not flow or pass through apertures predictably. A flat particle might lie across an opening it should have passed through, leading to it being recorded in a much larger size fraction than its actual dimensions would suggest.

Operational and Mechanical Drawbacks

Beyond theoretical assumptions, the physical operation of a sieve shaker introduces other potential sources of error.

Risk of Particle Attrition

The vigorous shaking motion required for sieving can damage the sample itself. This is known as attrition.

Brittle materials can break apart during the analysis, creating finer particles. This artificially skews the results, suggesting the original sample was finer than it actually was.

Sieve Clogging and Blinding

Particles that are very close to the size of the mesh openings can become lodged in the apertures. This phenomenon, known as blinding, effectively reduces the available area for sieving.

When a sieve is blinded, it prevents other, smaller particles from passing through, leading to inefficient separation and inaccurate results.

Wear, Tear, and Distortion

Sieves are physical instruments that are subject to wear. Over time and with improper handling, the wire mesh can stretch, warp, or become distorted.

Any change to the aperture size compromises the accuracy and reproducibility of the test. Regular inspection and calibration are critical to mitigate this disadvantage.

Understanding the Trade-offs

The disadvantages of the sieve shaker method must be weighed against its significant benefits in the right context. It is a tool with a specific purpose.

Simplicity vs. Precision

The sieve shaker is inexpensive, easy to operate, and requires minimal training. This simplicity comes at the cost of the high precision offered by more advanced methods like laser diffraction, which can provide much higher resolution data, especially for fine particles.

Speed vs. Definitive Characterization

For many quality control applications, a sieve analysis provides results quickly. However, that speed means you only get a size distribution. You gain no insight into the particle's shape, surface area, or other morphological characteristics that methods like image analysis can provide.

When the Disadvantages Are Minimal

For coarse, free-flowing, and relatively spherical materials (such as sand, grains, or plastic pellets), most of these disadvantages are negligible. In these applications, the sieve shaker remains an exceptionally effective, reliable, and cost-efficient tool.

Making the Right Choice for Your Material

Selecting the correct particle analysis method depends entirely on the nature of your material and the data you need.

- If your primary focus is quality control of coarse, free-flowing materials (>150 µm): The sieve shaker's speed and simplicity make its disadvantages largely irrelevant for your goal.

- If your primary focus is analyzing fine powders or nanomaterials (<50 µm): The sieve shaker method is unsuitable, and you should use alternative methods like laser diffraction or dynamic light scattering.

- If your primary focus is characterizing irregularly shaped particles (e.g., fibers, flakes): The sieve shaker will provide misleading data, and automated image analysis is a far more appropriate technique.

Ultimately, understanding these limitations is the key to correctly interpreting your results and choosing the right analytical tool for the job.

Summary Table:

| Disadvantage | Impact on Analysis |

|---|---|

| Assumes Spherical Particles | Mischaracterizes elongated, flat, or fibrous materials. |

| Ineffective for Fine Powders (< 50 µm) | Struggles with agglomeration and blinding; unsuitable for nanomaterials. |

| Particle Attrition | Vigorous shaking can break brittle samples, skewing results. |

| Sieve Wear and Clogging | Leads to inaccurate and non-reproducible data over time. |

| Limited Data Output | Provides only size distribution, no shape or surface area data. |

Struggling with inaccurate particle sizing? The limitations of a sieve shaker can compromise your lab's data integrity and efficiency. For fine powders, nanomaterials, or irregularly shaped particles, a more advanced technique is essential.

KINTEK specializes in precise lab equipment and consumables to meet your specific particle analysis needs. We can help you select the right technology—from laser diffraction to image analysis systems—to ensure accurate, reliable results for your materials.

Contact our experts today to discuss your application and find the optimal solution for your laboratory.

Visual Guide

Related Products

- Laboratory Test Sieves and Sieving Machines

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Laboratory Single Horizontal Jar Mill

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

People Also Ask

- How do crushing and sieving systems facilitate bioactive extraction? Boost Yield in Tilia cordata Research

- What is the purpose of using a high-energy shaker mill for Na2B12H12? Unlock Peak Ionic Conductivity

- What is the primary function of a mechanical sieve shaker for biomass analysis? Optimize Particle Size Distribution

- Why is a multi-stage vibrating sieve system used for sisal residue powders? Maximize Yield and Efficiency

- What are the principles of a sieve shaker? Achieve Accurate Particle Size Analysis

- How do air classifiers or sieving machines contribute to methane pyrolysis? Refine Carbon Black for Market Success

- How long does a sieve analysis shaker take? A Realistic Breakdown of the Full Process

- What is the role of a constant temperature shaker in PHA production? Optimize Microorganism Screening and Growth