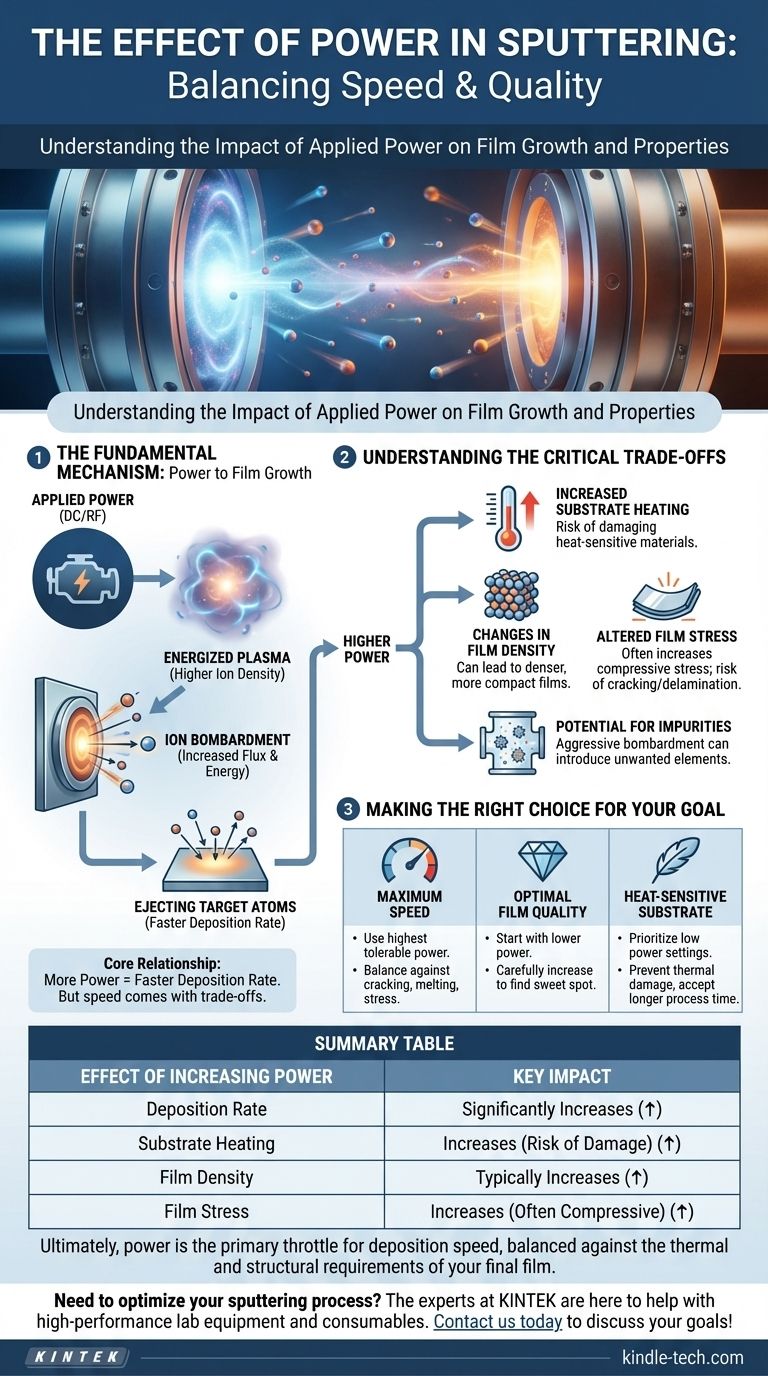

In sputtering, the primary effect of increasing power is a direct and significant increase in the deposition rate. Higher power energizes more ions within the plasma, causing them to strike the target material with greater force and frequency. This enhanced bombardment ejects more atoms from the target, which then travel to and coat the substrate, building a thicker film in less time.

The core relationship is simple: more power equals a faster deposition rate. However, this speed comes with critical trade-offs, most notably increased substrate heating and potential changes in the film's final properties like stress and density.

The Fundamental Mechanism: From Power to Film Growth

To understand the consequences of changing power, we must first understand how that power drives the sputtering process. The applied power is the engine that creates and sustains the plasma environment essential for deposition.

Energizing the Plasma

The electrical power, whether DC or RF, is what ionizes the inert gas (typically Argon) inside the vacuum chamber, creating a plasma. Increasing the power increases the density of this plasma, meaning there are more high-energy ions available to do the work.

Ion Bombardment and Momentum Transfer

As described by the core physics of sputtering, these high-energy ions are accelerated towards the target material. The increased power results in a higher ion flux (more ions hitting the target per second) and can increase the average ion energy.

This leads to more forceful collisions and a more efficient momentum transfer from the ions to the target atoms.

Ejecting Target Atoms

When the energy transferred during these collisions exceeds the bonding energy of the target's atoms, an atom is ejected. This process is the essence of sputtering. A higher power level creates more of these energetic collisions, dramatically increasing the number of atoms ejected from the target and, consequently, the rate at which the film grows on your substrate.

Understanding the Critical Trade-offs

While increasing power is the easiest way to speed up a deposition, it is not a "free" adjustment. The extra energy you introduce into the system has several secondary effects that can be either beneficial or detrimental depending on your goal.

Increased Substrate Heating

This is the most significant side effect. The increased energy from the plasma and the bombarding atoms is transferred to the substrate, causing its temperature to rise. This can easily damage heat-sensitive substrates, such as polymers or organic materials, which can degrade under ionic bombardment.

Changes in Film Density

A more energetic deposition process can lead to denser, more compact films. The depositing atoms arrive at the substrate with higher kinetic energy, allowing them to arrange themselves into a more tightly packed structure. This can be a desirable outcome for applications requiring robust coatings.

Altered Film Stress

The downside of a more energetic deposition is often an increase in compressive stress within the film. While some compressive stress can be good, excessive levels can cause the film to crack, wrinkle, or even peel off the substrate entirely (delamination).

Potential for Impurities

While the references note that sputtering is susceptible to impurities from the vacuum environment, very high power can exacerbate this. Aggressive bombardment can heat chamber components or sputter material from shields and fixtures, potentially introducing unwanted elements into your film.

Making the Right Choice for Your Goal

Selecting the correct power level requires balancing the need for speed against the requirements for film quality and substrate integrity. Your decision should be guided by the primary objective of your deposition.

- If your primary focus is maximum deposition speed: Use the highest power your target and substrate can tolerate without cracking, melting, or causing unacceptable stress in the film.

- If your primary focus is optimal film quality: Begin with a lower power setting to ensure a more controlled, gentle deposition, and then carefully increase it to find the sweet spot before film stress or heat become problematic.

- If your primary focus is coating a heat-sensitive substrate: You must prioritize low power settings to prevent thermal damage, even if it results in a much longer process time.

Ultimately, power is the primary throttle for deposition speed, but it must be carefully balanced against the thermal and structural requirements of your final film.

Summary Table:

| Effect of Increasing Power | Key Impact |

|---|---|

| Deposition Rate | Significantly Increases |

| Substrate Heating | Increases (Risk of Damage) |

| Film Density | Typically Increases |

| Film Stress | Increases (Often Compressive) |

Need to optimize your sputtering process for the perfect balance of speed and quality? The experts at KINTEK are here to help. We specialize in providing high-performance lab equipment and consumables tailored to your specific deposition goals. Whether you're coating heat-sensitive materials or require dense, low-stress films, our solutions ensure reliable results. Contact us today to discuss how we can enhance your laboratory's capabilities!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Graphite Vacuum Furnace IGBT Experimental Graphitization Furnace

People Also Ask

- Why is a high-frequency ultrasonic cleaner necessary for steel substrate preparation? Achieve 100% Coating Adhesion

- What is vacuum lamination? Achieve a Flawless, Durable Finish on Complex Shapes

- How is a multi-channel potentiostat used in fixed-bed bioelectrochemical systems? Optimize Spatial Mapping & Control

- What are rapid sintering techniques? Unlock Faster, Stronger Material Production

- What is the significance of 1°C/min cooling for alloy experiments? Mitigate Stress & Ensure SEM Data Accuracy

- What is the difference between electric arc furnace and plasma arc furnace? Choose the Right Tool for Your Heat Processing Needs

- What are the different types of brazing methods? Find the Right Heating Technique for Your Project

- What are the characteristics of sintering? Master Controlled Porosity and High-Performance Materials