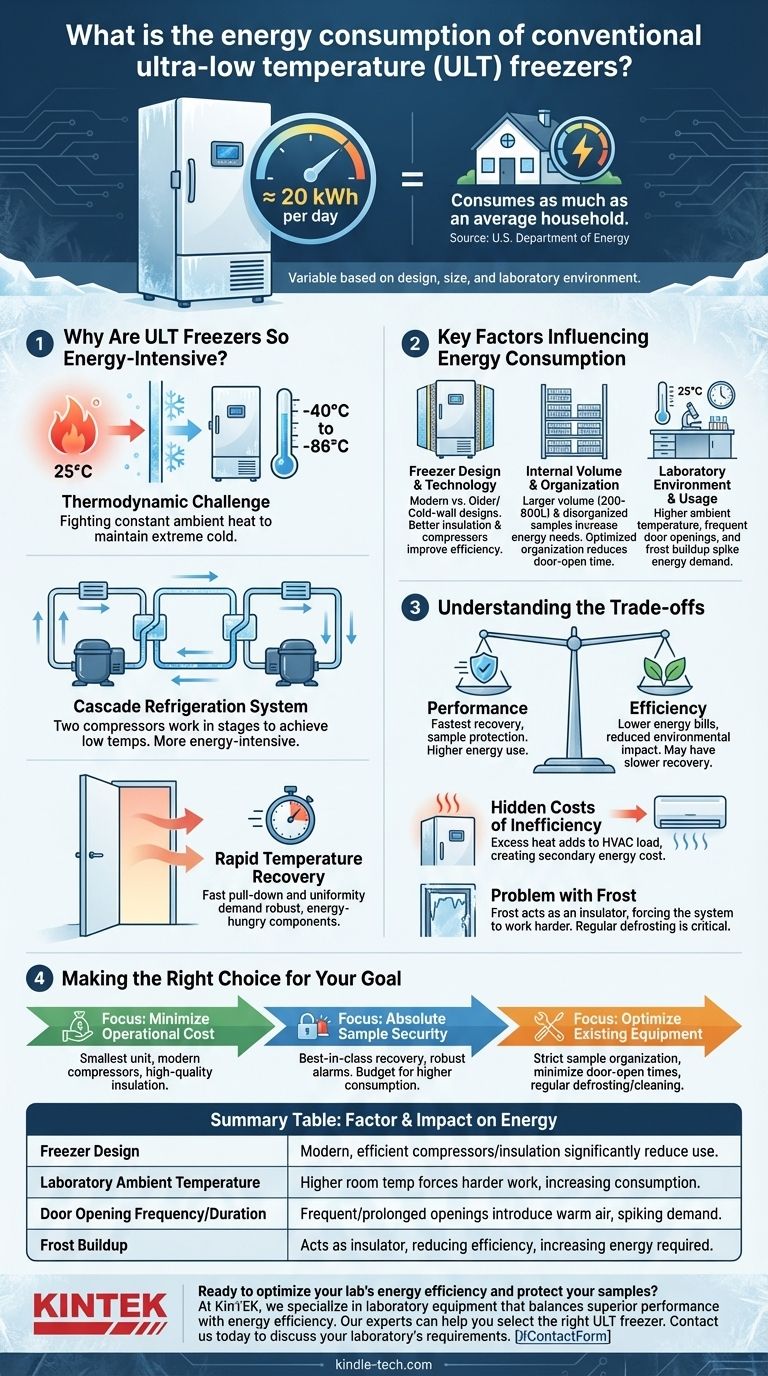

To put it directly, a conventional ultra-low temperature (ULT) freezer consumes a significant amount of energy, often as much as an average household. According to the U.S. Department of Energy, this can be approximately 20 kilowatt-hours (kWh) per day. This high consumption is a direct consequence of the extreme temperatures these units must constantly maintain to preserve sensitive biological samples.

While the 20 kWh/day figure is a critical benchmark, the true energy cost of a ULT freezer is not fixed. It is a variable dependent on the freezer's specific design, its size, and, most importantly, the environment and practices within your laboratory.

Why Are ULT Freezers So Energy-Intensive?

Understanding the high energy draw of ULT freezers begins with appreciating the thermodynamic challenge they overcome. They are not merely cold; they are fighting a constant battle against ambient heat to maintain temperatures far below freezing.

The Challenge of Extreme Cold

A standard freezer cools to around -20°C. A ULT freezer, however, must operate in a much more demanding range, typically between -40°C and -86°C.

Maintaining this differential requires a powerful and continuously operating refrigeration system to extract heat that inevitably leaks into the cabinet from the surrounding room.

The Cascade Refrigeration System

To achieve such low temperatures, most ULT freezers use a cascade refrigeration system. This involves two separate refrigeration circuits that work in stages.

The first circuit cools the second, allowing the second circuit to reach a much colder temperature than a single system ever could. While effective, running two compressors is inherently more energy-intensive than running one.

Maintaining Temperature Stability

ULT freezers are engineered for performance, which includes rapid temperature recovery after a door opening. When the door is opened, warm, moist air rushes in, and the system must work overtime to expel that heat and return to its setpoint.

Features like fast temperature pull-down and uniformity, while critical for sample integrity, demand robust compressors and fans that contribute directly to the high energy bill.

Key Factors Influencing Energy Consumption

Not all ULT freezers are created equal. The 20 kWh/day figure is an average for conventional units, and several factors can cause this number to vary significantly.

Freezer Design and Technology

Older or more basic designs, such as cold-wall freezers, cool the chamber via refrigerant lines in the walls. These can suffer from poor temperature uniformity and slower recovery times, forcing the system to run longer and less efficiently. Modern designs often have superior insulation and more efficient compressor technology.

Internal Volume and Organization

The internal volume of ULT freezers typically ranges from 200 to 800 litres. A larger volume naturally requires more energy to cool and maintain.

Furthermore, how you organize samples is critical. Well-organized racks and the use of internal doors for each shelf minimize the time the main door is open, reducing the influx of warm air.

Laboratory Environment and Usage

The ambient temperature of your lab has a direct impact. A freezer in a 25°C room has to work much harder than one in a 20°C room.

Frequent door openings, prolonged opening times, and frost buildup all force the refrigeration system into high-demand cycles, dramatically increasing energy use.

Understanding the Trade-offs

Choosing or operating a ULT freezer involves balancing competing priorities. Understanding these trade-offs is essential for making an informed decision.

Performance vs. Efficiency

The most robust freezers with the fastest temperature pull-down and recovery rates are often the most energy-intensive. Their powerful systems are optimized for sample protection above all else. You must weigh the absolute need for high performance against long-term operational costs.

The Hidden Costs of Inefficiency

The energy bill is only part of the story. A freezer consuming 20 kWh of electricity per day also releases that energy as heat into the laboratory. This adds a significant load to your building's HVAC system, creating a secondary energy cost.

The Problem with Frost

Frost is an insulator. A layer of ice buildup on the door seals and inner doors forces the freezer to work harder to maintain its setpoint. Regular defrosting and cleaning are not just about maintenance; they are critical for energy efficiency.

Making the Right Choice for Your Goal

Your optimal strategy depends entirely on your primary objective, whether you are purchasing new equipment or optimizing what you already have.

- If your primary focus is minimizing operational cost: Select the smallest freezer that meets your capacity needs and prioritize models with modern, energy-efficient compressors and high-quality insulation.

- If your primary focus is absolute sample security: Look for units with best-in-class temperature recovery times and robust alarm systems, but budget accordingly for their higher energy consumption.

- If your primary focus is optimizing existing equipment: Implement strict protocols for sample organization to minimize door-open times and commit to a regular schedule of defrosting and cleaning the door seals.

Ultimately, managing the energy consumption of a ULT freezer is an act of balancing the protection of invaluable samples with the realities of operational efficiency.

Summary Table:

| Factor | Impact on Energy Consumption |

|---|---|

| Freezer Design | Modern, efficient compressors and insulation significantly reduce energy use. |

| Laboratory Ambient Temperature | A higher room temperature forces the freezer to work harder, increasing consumption. |

| Door Opening Frequency/Duration | Frequent or prolonged openings introduce warm air, spiking energy demand for recovery. |

| Frost Buildup | Frost acts as an insulator, reducing efficiency and increasing the energy required. |

Ready to optimize your lab's energy efficiency and protect your samples?

The high energy consumption of ULT freezers is a major operational cost. At KINTEK, we specialize in providing laboratory equipment and consumables that balance superior performance with energy efficiency. Our experts can help you select the right ULT freezer for your specific needs, ensuring sample security while managing your long-term costs.

Contact us today to discuss your laboratory's requirements and discover how we can help you achieve your goals for performance, reliability, and efficiency. #ContactForm

Visual Guide

Related Products

- 938L Vertical Ultra Low Temperature Freezer for Advanced Laboratory Storage

- 508L Advanced Vertical Ultra Low Temperature Freezer for Critical Laboratory Storage

- 408L Advanced Vertical Laboratory Ultra Low Temperature Freezer for Critical Research Material Preservation

- 608L Essential Laboratory Ultra Low Temperature Freezer For Critical Sample Preservation

- 28L Compact Upright Ultra Low Temperature Freezer for Laboratory

People Also Ask

- How do I prepare my house for bed bug heat treatment? A Guide to Ensuring Total Elimination

- What is the major product of slow pyrolysis? Maximizing Biochar for Carbon Sequestration

- What are the 3 types of biomass energy sources? Unlock the Potential of Organic Materials

- Why pre sintering is required for some metals? The Key to Defect-Free Powder Metal Parts

- What is sinter metal? A Guide to Cost-Effective, Complex Metal Parts

- What are two different uses of a water bath in biological investigations? Precise Temperature Control for Reliable Results

- What should be the voltage pulse in high power pulsed magnetron sputtering? Mastering HiPIMS for Superior Film Control

- Can CBD be distilled? A Guide to High-Purity CBD Concentrate Production