At its core, a ball mill is a grinding machine that uses a tumbling motion to reduce the size of materials. The process involves placing the material into a rotating cylinder along with a grinding medium—typically steel or ceramic balls—which crush and grind the material through continuous impact and friction as the cylinder turns.

The effectiveness of a ball mill does not come from the machine itself, but from the controlled chaos within it. The key is to manage rotational speed and the volume of grinding media to create a "cascading" effect that maximizes the forces of impact and attrition.

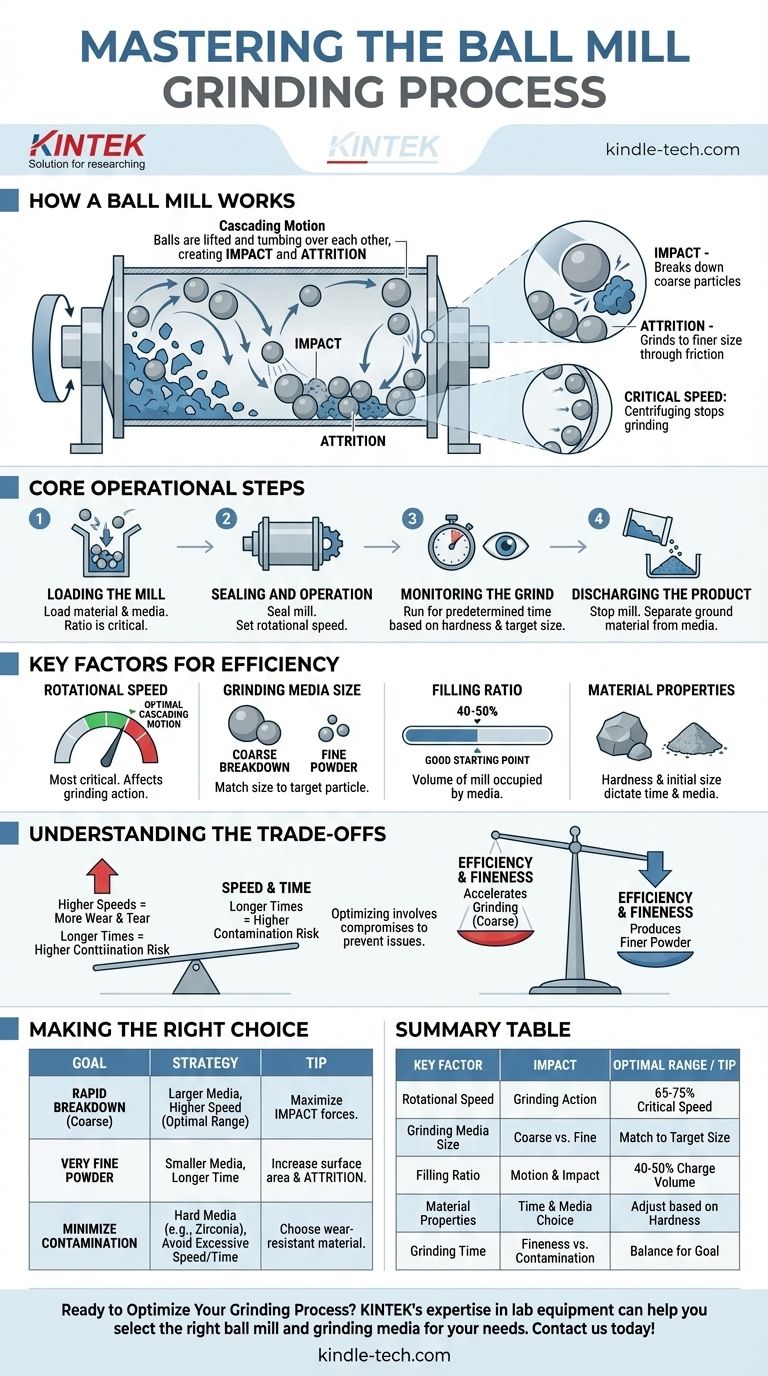

The Mechanics of Grinding: Impact and Attrition

A ball mill reduces particle size through two primary mechanisms that work in tandem. Understanding these forces is the first step to controlling the grinding process.

The Power of Impact

As the mill cylinder rotates, it lifts the grinding balls and the material. At a certain point, the balls begin to tumble down, striking the material below. This forceful collision, known as impact, is responsible for breaking down larger, coarse particles.

The Finesse of Attrition

Simultaneously, the balls rub against each other, the mill liner, and the material itself. This shearing and rubbing action, called attrition, is what grinds the particles down to a much finer size.

The Ideal State: Cascading Motion

The most efficient grinding occurs when the balls are continuously lifted just high enough to tumble over one another in a cascade. This motion ensures a constant combination of impact and attrition throughout the material charge.

The Limit: Critical Speed

If the mill rotates too quickly, centrifugal force will cause the balls to stick to the wall of the cylinder. This is known as "centrifuging," and at this point, all grinding action stops because there is no tumbling or impact. The minimum speed at which this occurs is called the critical speed.

Core Operational Steps

While specific procedures vary, the fundamental grinding process follows a clear sequence.

Step 1: Loading the Mill

The process begins by opening the mill's access port and loading the material to be ground. The grinding media (balls) are then added. The ratio of material to media is a critical parameter.

Step 2: Sealing and Operation

Once loaded, the mill is securely sealed. The machine is then started, and the rotational speed is carefully set to achieve the desired grinding action.

Step 3: Monitoring the Grind

The mill runs for a predetermined amount of time, which depends on the material's hardness and the target final particle size.

Step 4: Discharging the Product

After the cycle is complete, the machine is stopped. The ground material is then separated from the grinding media and discharged from the mill.

Key Factors That Determine Grinding Efficiency

Achieving a consistent and efficient grind depends on balancing several interconnected variables.

Rotational Speed

This is the most critical control factor. A speed between 65% and 75% of the critical speed is typically optimal for creating a strong cascading motion and maximizing grinding efficiency.

Grinding Media Characteristics

The size, material, and shape of the grinding media are crucial. Larger balls are used for breaking down coarse feed material, while smaller balls provide the greater surface area needed for producing a very fine final product.

The Filling Ratio

The volume of the mill occupied by the grinding media (the "charge volume") significantly affects performance. A fill of 40-50% is often a good starting point. Too little media results in inefficient grinding, while too much restricts motion and reduces impact energy.

Material Properties

The hardness, density, and initial size of the material being ground will dictate the required grinding time and the optimal choice of grinding media.

Understanding the Trade-offs

Optimizing the ball milling process always involves compromises. Being aware of them is key to preventing common mistakes.

Speed vs. Wear and Tear

Operating at higher speeds can accelerate grinding, but it also dramatically increases the rate of wear on both the grinding media and the mill's internal liner. This leads to higher operational costs and potential product contamination.

Grinding Time vs. Contamination

The longer the mill runs, the finer the resulting powder. However, extended run times also increase the opportunity for contamination as tiny particles of the grinding media wear off and mix with the product.

Media Size vs. Final Particle Size

Large media are excellent for coarse grinding but are inefficient at producing ultra-fine powders. Conversely, small media are perfect for fine grinding but cannot effectively break down large input particles. This may necessitate a multi-stage grinding process.

Making the Right Choice for Your Goal

Your specific objective should dictate how you set up and run the mill.

- If your primary focus is the rapid breakdown of coarse material: Use larger, heavier grinding media and operate at the higher end of the optimal speed range to maximize impact forces.

- If your primary focus is achieving a very fine final powder: Use smaller grinding media to increase surface area contact and attrition, and plan for longer grinding times.

- If your primary focus is minimizing product contamination: Choose grinding media made from a very hard, wear-resistant material (like zirconia) and avoid excessive speeds or unnecessarily long grinding times.

Mastering the ball mill is about balancing these variables to create the precise grinding environment your material requires.

Summary Table:

| Key Factor | Impact on Grinding Process | Optimal Range / Tip |

|---|---|---|

| Rotational Speed | Determines the grinding action (cascading vs. centrifuging). | 65-75% of critical speed for best cascade. |

| Grinding Media Size | Larger balls for coarse grinding; smaller for fine powders. | Match media size to your target particle size. |

| Filling Ratio | Affects motion and impact energy of the media. | Start with a 40-50% media charge volume. |

| Material Properties | Hardness and initial size dictate grinding time and media choice. | Adjust time and media based on material hardness. |

| Grinding Time | Longer times yield finer particles but increase contamination risk. | Balance fineness with contamination control. |

Ready to Optimize Your Grinding Process?

Whether you're breaking down coarse materials or aiming for ultra-fine powders, KINTEK's expertise in lab equipment can help you select the right ball mill and grinding media for your needs. We specialize in providing durable, efficient solutions for laboratories focused on precise particle size reduction.

Contact us today to discuss your grinding challenges and discover how KINTEK can enhance your lab's efficiency and results!

Visual Guide

Related Products

- Laboratory Single Horizontal Jar Mill

- High-Energy Omnidirectional Planetary Ball Mill Milling Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Machine for Laboratory

- High Energy Planetary Ball Mill Milling Machine for Laboratory

- Laboratory Horizontal Planetary Ball Mill Milling Machine

People Also Ask

- Why use zirconia ball milling jars for SiC/ZTA composite powders? Ensure High Purity & Efficient Particle Refinement

- What is the benefit of using tungsten carbide (WC) milling jars and balls? Achieve High-Energy Milling Efficiency

- Why are tungsten carbide grinding jars and balls preferred for high-purity lithium ceramic powders? Ensure Peak Purity.

- What is the ball mill based on the principle of? Impact and Attrition for Efficient Grinding

- Why are excellent sealing and corrosion resistance required for WC-10Co ball milling? Ensure High-Purity Mixing Results