At its core, the rotational speed of a ball mill dictates the grinding mechanism. Too slow a speed results in insufficient impact, while too fast a speed causes the grinding media to stick to the mill's wall, halting the process entirely. The optimal speed is a carefully controlled percentage of the mill's "critical speed," which maximizes the combination of impact and attrition forces needed for effective particle size reduction.

The primary goal is not to achieve maximum rotation, but to operate at a specific percentage of the mill's "critical speed." This optimal range ensures the grinding media cascades and tumbles effectively, maximizing the energy required for efficient grinding.

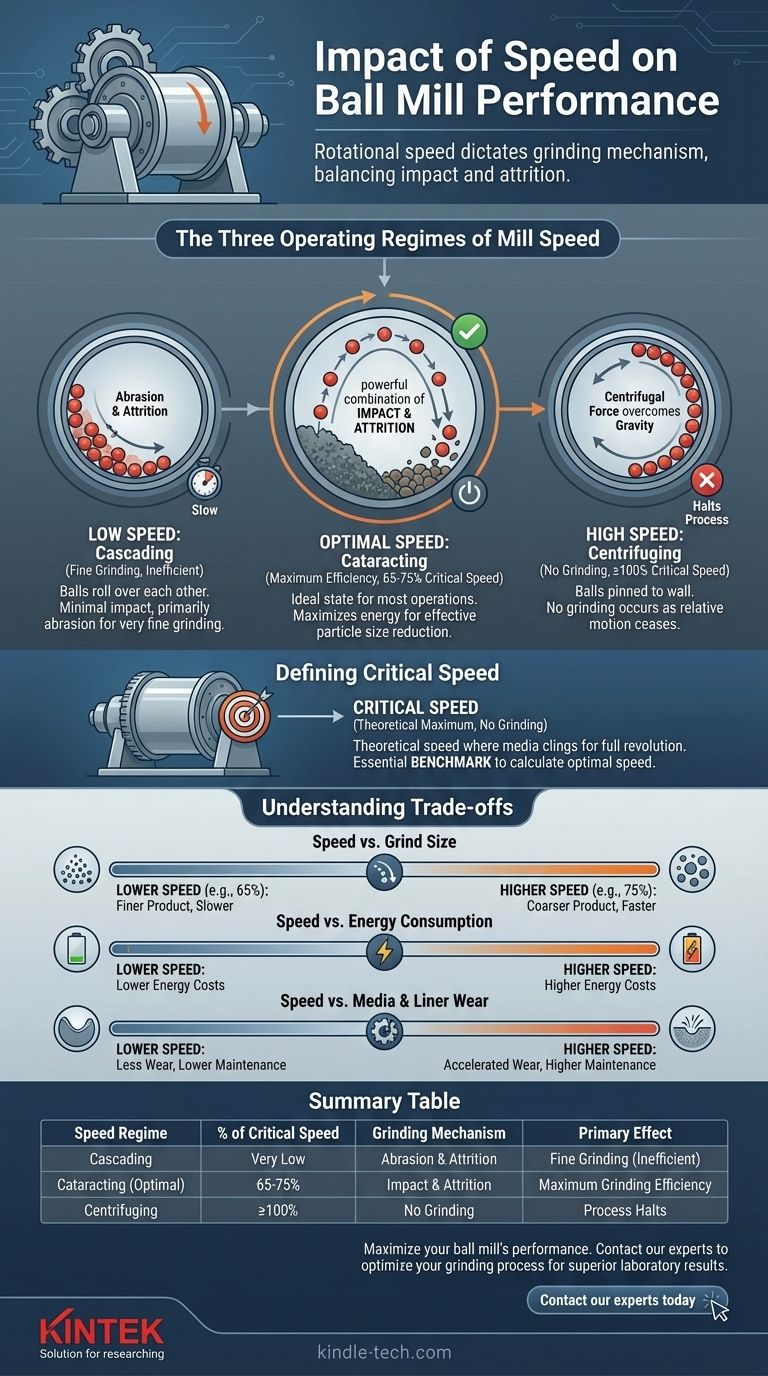

The Three Operating Regimes of Mill Speed

The effect of speed on grinding action can be understood by breaking it down into three distinct states of motion for the grinding media (the balls).

The Low-Speed Regime (Cascading)

At very low speeds, the balls are lifted only a short distance up the side of the mill before they gently tumble or roll over each other down the surface of the charge.

This motion, known as cascading, produces minimal impact force. Grinding is achieved primarily through abrasion, which is suitable for very fine grinding but is generally inefficient for overall size reduction.

The Optimal Speed Regime (Cataracting)

As speed increases to the optimal range (typically 65-75% of critical speed), the balls are carried further up the mill wall. They then break contact and follow a parabolic path, falling onto the material at the bottom of the mill.

This is known as cataracting. It is the ideal state for most grinding operations because it creates a powerful combination of impact (from the falling balls) and attrition (from the tumbling motion at the toe of the charge).

The High-Speed Regime (Centrifuging)

If the mill's speed reaches or exceeds the critical speed, centrifugal force overcomes gravity. The grinding media becomes pinned against the mill's inner wall, rotating with it as a single mass.

In this state, known as centrifuging, all relative motion between the balls and the material ceases. As a result, no grinding occurs.

Defining Critical Speed

Understanding the concept of critical speed is fundamental to controlling any ball mill operation.

What is Critical Speed?

Critical speed is the theoretical rotational speed at which the innermost layer of grinding media will cling to the mill liner for a full revolution.

Why It Matters

The critical speed itself is not a target you aim to achieve. Instead, it serves as the essential benchmark from which you calculate your optimal operating speed.

All effective mill speeds are expressed as a percentage of this critical value, allowing for consistent process control regardless of the mill's diameter.

Understanding the Trade-offs

Choosing a speed is not just about the grinding action; it involves balancing competing operational factors.

Speed vs. Grind Size

Higher speeds within the optimal range (e.g., 75% of critical) favor impact forces. This is more effective for breaking down larger particles and achieving faster, coarser grinding.

Lower speeds (e.g., 65% of critical) favor attrition and cascading. This is often better for achieving a finer final product, though it may take more time.

Speed vs. Energy Consumption

Higher rotational speeds demand more power to operate the mill. Running at the upper end of the optimal range will result in higher energy costs per hour of operation.

Speed vs. Media and Liner Wear

The forceful impacts generated at higher speeds lead to accelerated wear on both the grinding media and the mill's internal protective liners. This increases maintenance frequency and operational costs over time.

Selecting the Right Speed for Your Application

There is no single "best" speed; the correct choice depends entirely on your process goals.

- If your primary focus is coarse grinding or rapid size reduction: Operate at the higher end of the optimal range, typically 70-75% of critical speed, to maximize impact forces.

- If your primary focus is producing very fine particles: Operate at the lower end of the optimal range, around 65-70% of critical speed, to promote more abrasive, cascading action.

- If your primary focus is balancing throughput, energy costs, and equipment life: Start in the middle of the optimal range (around 70%) and adjust based on product analysis and wear inspection.

Ultimately, mastering mill speed is about treating it not as a throttle, but as a precise control for targeting a specific grinding outcome.

Summary Table:

| Speed Regime | % of Critical Speed | Grinding Mechanism | Primary Effect |

|---|---|---|---|

| Cascading | Very Low | Abrasion & Attrition | Fine Grinding (Inefficient) |

| Cataracting (Optimal) | 65-75% | Impact & Attrition | Maximum Grinding Efficiency |

| Centrifuging | ≥100% | No Grinding | Process Halts |

Maximize your ball mill's performance and efficiency. The precise control of mill speed is critical for achieving your target particle size while managing energy consumption and equipment wear. KINTEK specializes in lab equipment and consumables, providing the expertise and solutions you need to optimize your grinding processes. Contact our experts today to discuss how we can help you achieve superior grinding results for your laboratory needs.

Visual Guide

Related Products

- High-Energy Omnidirectional Planetary Ball Mill Milling Machine for Laboratory

- High Energy Planetary Ball Mill Milling Machine for Laboratory

- Laboratory Planetary Ball Mill Rotating Ball Milling Machine

- High-Energy Omnidirectional Planetary Ball Mill Machine for Laboratory

- High Energy Planetary Ball Mill Milling Machine for Laboratory

People Also Ask

- What is the purpose of grinding bulk solid catalysts into fine powder? Maximize Surface Area and Catalytic Efficiency

- Why is the pelletizing, crushing, and sieving of biomass raw materials necessary? Ensure Gasification Stability

- What grinding media is used in a ball mill? Select the Right Media for Maximum Efficiency and Purity

- What is the speed range of a ball mill? Find Your Optimal Grinding Efficiency

- How do stainless steel grinding balls function as energy transfer media in the preparation of magnesium-based composites?

- What does a colloid mill produce? Create Ultra-Fine Emulsions and Dispersions

- Why is a high-energy vibrating mill necessary for LiF–NaF–KF mixtures? Achieve Precise Oxygen Analysis Calibration

- What are the advantages of ball milling process? Achieve Nanoscale Materials & Alloying