In industrial processing, sieving is the foundational method for separating materials based on particle size. While it seems simple, this mechanical sorting process is a critical control point that directly impacts final product quality, operational safety, and manufacturing efficiency across countless sectors. It is the gatekeeper that ensures only correctly sized particles proceed to the next stage of production.

Beyond simply sorting materials, industrial sieving is an essential quality control mechanism. The size of a particle dictates its physical and chemical properties, and controlling this single variable is fundamental to ensuring a product is safe, effective, and consistent.

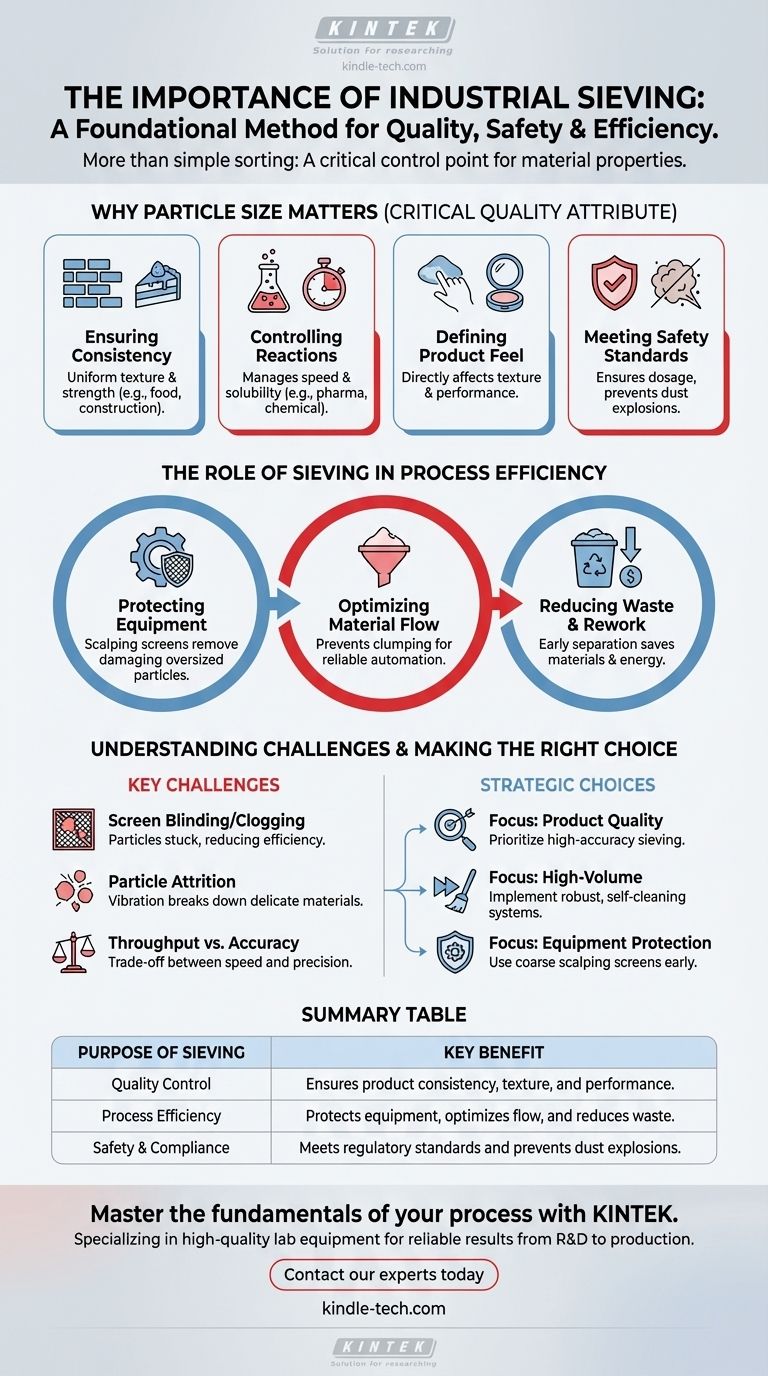

Why Particle Size is a Critical Quality Attribute

The physical size of particles in a bulk solid is not a trivial detail; it is a primary characteristic that defines how the material behaves. Controlling the particle size distribution (PSD) is therefore essential for manufacturing.

Ensuring Product Consistency and Uniformity

A consistent product is a reliable product. In the food industry, sieving ensures that a cake mix has the right texture and baking properties. In construction, it guarantees that the aggregates in concrete are correctly graded for maximum strength.

Controlling Reaction Rates and Solubility

Smaller particles have a larger surface area relative to their volume. This principle is critical in chemical and pharmaceutical manufacturing, where sieving is used to control the size of reactants to manage reaction speed or ensure a drug dissolves in the body at the precise, intended rate.

Defining Final Product Feel and Performance

The tactile properties of many products are a direct result of particle size. Sieving helps create the smooth texture of cosmetics, the specific abrasive quality of industrial cleaners, and the free-flowing nature of powdered drink mixes.

Meeting Regulatory and Safety Standards

Many industries have strict regulations regarding particle size. In pharmaceuticals, it's about ensuring correct dosage and bioavailability. In environments with combustible dust, removing fine particles through sieving is a critical step in preventing the risk of dust explosions.

The Role of Sieving in Process Efficiency

Sieving isn't just about the final product; it's also about optimizing the entire manufacturing line. An effective sieving strategy protects equipment, saves money, and improves throughput.

Protecting Downstream Equipment

Oversized particles or foreign contaminants can severely damage sensitive downstream machinery like mills, mixers, and pumps. A simple, coarse screen—often called a "scalping" screen—placed at the beginning of a process can prevent costly damage and downtime.

Optimizing Material Flow

Powders and granules that have a uniform particle size distribution flow more predictably and are less prone to clumping, bridging, or clogging in hoppers and conveyors. Sieving ensures this consistent flow, which is vital for automated processes.

Reducing Waste and Rework

By separating out-of-spec particles early, manufacturers can either discard them or re-route them for further processing (like milling). This prevents an entire batch from being ruined by incorrect particle size, saving both raw materials and energy.

Understanding the Limitations and Challenges

While essential, sieving is a mechanical process with inherent trade-offs that must be managed for it to be effective.

Screen Blinding and Clogging

This is the most common issue, where particles get stuck in the mesh openings, reducing the screen's effective area and lowering efficiency. This is particularly problematic with damp, sticky, or irregularly shaped materials.

Particle Attrition

The mechanical vibration or movement used in many sieving systems can break down friable or delicate materials. This degradation, known as attrition, can create unwanted fine dust and alter the final particle size distribution.

Throughput vs. Accuracy

There is a fundamental trade-off between how fast you can process material and how accurately you can separate it. Achieving a very precise size cut often requires slower processing speeds, while high-volume operations may have to accept a less precise separation.

Making the Right Choice for Your Goal

The optimal sieving strategy depends entirely on the material being processed and the desired outcome.

- If your primary focus is product quality and safety: Prioritize high-accuracy sieving and regular screen inspection, even if it reduces throughput, to ensure a precise particle size distribution.

- If your primary focus is high-volume processing: Implement robust, self-cleaning systems (using ultrasonic deblinding or mechanical cleaners) to maximize throughput for less sensitive materials like aggregates or recycled goods.

- If your primary focus is protecting equipment: Use coarse scalping screens at the beginning of your process to remove oversized contaminants before they can cause damage.

Ultimately, mastering industrial sieving provides direct control over a fundamental material property, transforming an inconsistent raw substance into a predictable and valuable final product.

Summary Table:

| Purpose of Sieving | Key Benefit |

|---|---|

| Quality Control | Ensures product consistency, texture, and performance. |

| Process Efficiency | Protects equipment, optimizes flow, and reduces waste. |

| Safety & Compliance | Meets regulatory standards and prevents dust explosions. |

Master the fundamentals of your process with KINTEK.

Particle size distribution is a critical quality attribute that directly impacts your final product. Whether you need to ensure precise particle sizing for pharmaceuticals, improve the texture of food products, or protect your equipment from damaging contaminants, the right sieving solution is key.

KINTEK specializes in high-quality lab equipment and consumables for all your sieving and particle analysis needs. Our expertise helps laboratories achieve consistent, reliable results that drive quality and efficiency from R&D to production.

Contact our experts today to discuss how we can support your specific sieving and separation challenges.

Visual Guide

Related Products

- Laboratory Test Sieves and Vibratory Sieve Shaker Machine

- Three-dimensional electromagnetic sieving instrument

- Laboratory Vibratory Sieve Shaker Machine for Dry and Wet Three-Dimensional Sieving

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Vibratory Sieve Shaker Machine Dry Three-Dimensional Vibrating Sieve

People Also Ask

- Why is a laboratory sieving system required for bentonite in coatings? Ensure Flawless Surface Performance

- Why is a laboratory electromagnetic vibratory sieve shaker used? Optimize Walnut Shell Chemical Pretreatment

- Why is powder classification using standard sieves essential for SHS reactions? Unlock Superior Nitriding Results

- What are the disadvantages of sieve machine? Key Limitations in Particle Size Analysis

- Why use a vibratory sieve shaker for PET powder? Achieve Precise Particle Size Control for Chemical Research