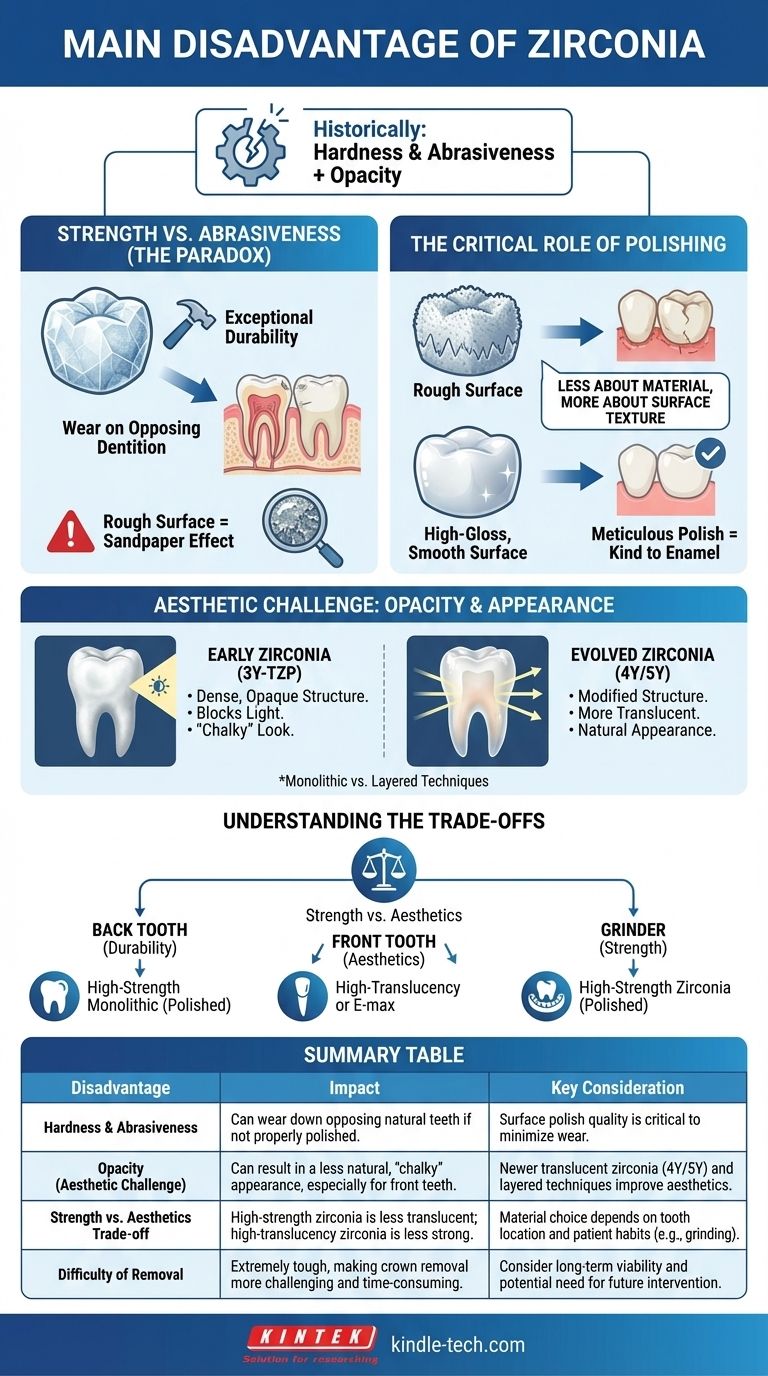

Historically, the main disadvantage of zirconia has been its hardness and abrasiveness, which can cause significant wear on the opposing natural teeth. A secondary, but equally important, drawback is its opacity, which can result in a less natural, "chalky" appearance compared to other ceramic materials, especially for front teeth.

Zirconia's greatest strength—its exceptional durability—is also the source of its primary clinical liabilities. However, these disadvantages are not absolute; they are highly dependent on the specific type of zirconia used and, most critically, the final polish of the restoration.

The Paradox: Strength vs. Abrasiveness

The core challenge with zirconia stems from its incredible material strength, a quality that also makes it a desirable dental material.

Understanding Zirconia's Hardness

Zirconia used in dentistry is zirconium dioxide, a ceramic that is "stabilized" in a crystalline structure to prevent it from cracking under pressure. This structure makes it exceptionally hard and resistant to fracture, far more so than natural tooth enamel or other ceramics like porcelain.

This is why it's a premier choice for crowns on back molars, where biting forces are immense, and for patients who grind their teeth (bruxism).

The Impact on Opposing Dentition

The problem arises when this ultra-hard material occludes with a softer material, namely natural tooth enamel. If the surface of the zirconia crown is not perfectly smooth, it acts like fine-grain sandpaper, gradually wearing down the opposing tooth with every bite and movement.

This wear is a serious clinical concern, as it can lead to loss of tooth structure, changes in bite, and sensitivity on the opposing tooth.

The Critical Role of Polishing

Crucially, modern research shows that the abrasiveness of zirconia is less about the material itself and more about its surface texture.

A zirconia crown that is meticulously shaped and polished to a high-gloss, glass-smooth surface is exceptionally kind to opposing enamel. Conversely, a crown that is improperly adjusted in the mouth and left rough is guaranteed to cause damage. This makes the skill and diligence of the dental lab and clinician paramount.

The Aesthetic Challenge: Opacity and Appearance

While strength is a functional concern, the aesthetic limitations of zirconia have historically limited its use.

Why Early Zirconia Looked "Chalky"

The original, highest-strength zirconia (like 3Y-TZP) has a very dense, opaque crystalline structure. This structure is excellent at resisting fractures but is also very poor at allowing light to pass through it.

Natural teeth have a degree of translucency, especially at the incisal edge. The opacity of early zirconia blocked this light, resulting in a restoration that could look flat, lifeless, and obviously artificial, making it a poor choice for visible front teeth.

The Evolution to Translucent Zirconia

To solve the aesthetic problem, manufacturers developed newer formulations (often called 4Y and 5Y zirconia). These materials have a modified crystalline structure with more "cubic" phase crystals, which allows more light to pass through.

This results in a much more natural, translucent appearance that can blend beautifully with adjacent teeth, making it suitable for anterior restorations.

Monolithic vs. Layered Zirconia

Another technique to improve aesthetics is to use a strong, opaque zirconia core (for durability) and then layer it with more aesthetic, life-like porcelain.

This layered approach offers excellent aesthetics but introduces a new potential weak point: the bond between the porcelain and the zirconia. The porcelain can chip off the core, which is a common reason for failure in these types of crowns.

Understanding the Trade-offs

Choosing a dental material is never about finding a "perfect" option. It is about understanding the benefits and liabilities in a specific clinical context.

Strength vs. Aesthetics

There is a direct trade-off within the zirconia family itself. The newer, highly translucent zirconias that look better are not as strong as the older, more opaque formulations.

A high-strength zirconia is ideal for a back molar. A high-translucency zirconia is better for a front tooth, but it may not be strong enough for a patient with a heavy grinding habit.

Zirconia vs. Other Materials

Compared to lithium disilicate (E-max), zirconia is generally stronger but less translucent. E-max is often considered the gold standard for single-unit anterior aesthetics but may not be suitable for bridges or for patients who are heavy grinders.

Compared to Porcelain-Fused-to-Metal (PFM) crowns, monolithic zirconia eliminates the risk of porcelain chipping and avoids the "black line" at the gumline that can appear with PFMs.

The Risk of Removal

A final, practical disadvantage of zirconia is its sheer toughness. If a zirconia crown needs to be removed for any reason (such as decay underneath), cutting it off is significantly more difficult and time-consuming for the dentist than with any other material.

Making the Right Choice for Your Restoration

The "best" material is the one that best suits your specific tooth, bite, and aesthetic goals. Understanding these factors allows for a more productive conversation with your dental provider.

- If your primary focus is maximum durability for a back tooth: A full-strength, monolithic zirconia crown that is meticulously polished is an excellent and highly predictable choice.

- If your primary focus is optimal aesthetics for a front tooth: A high-translucency zirconia or lithium disilicate (E-max) are likely the top contenders to discuss.

- If your primary focus is managing a teeth grinding habit: The superior strength of zirconia makes it a leading candidate, but a conversation about proper polishing to protect opposing teeth is essential.

Ultimately, the disadvantages of zirconia are manageable variables, not absolute deterrents, turning the choice into a careful balance of strength, aesthetics, and clinical execution.

Summary Table:

| Disadvantage | Impact | Key Consideration |

|---|---|---|

| Hardness & Abrasiveness | Can wear down opposing natural teeth if not properly polished. | Surface polish quality is critical to minimize wear. |

| Opacity (Aesthetic Challenge) | Can result in a less natural, "chalky" appearance, especially for front teeth. | Newer translucent zirconia (4Y/5Y) and layered techniques improve aesthetics. |

| Strength vs. Aesthetics Trade-off | High-strength zirconia is less translucent; high-translucency zirconia is less strong. | Material choice depends on tooth location and patient habits (e.g., grinding). |

| Difficulty of Removal | Extremely tough, making crown removal more challenging and time-consuming. | Consider long-term viability and potential need for future intervention. |

Choosing the right dental restoration material is a precise science. At KINTEK, we specialize in providing high-quality dental lab equipment and consumables that empower dental laboratories to craft zirconia restorations with optimal polish and aesthetics. Whether you're working with monolithic or layered zirconia, our solutions help you balance durability and natural appearance for superior patient outcomes. Let's discuss your lab's specific needs—contact our experts today to enhance your restoration quality and efficiency.

Visual Guide

Related Products

- Engineering Advanced Fine Ceramics Head Tweezers with Pointed Elbow Zirconia Ceramic Tip

- Precision Machined Zirconia Ceramic Ball for Engineering Advanced Fine Ceramics

- Custom-Made Alumina Zirconia Special-Shaped Ceramic Plates for Engineering Advanced Fine Ceramics Processing

- Precision Machined Yttrium Stabilized Zirconia Ceramic Rod for Engineering Advanced Fine Ceramics

- Zirconia Ceramic Gasket Insulating Engineering Advanced Fine Ceramics

People Also Ask

- What is a sintering furnace for dental? The Key to Durable, High-Strength Ceramic Restorations

- What is the use of burnout oven? The Critical Step for Flawless Casting Results

- Does porcelain need to be fired? Discover the Essential Process for True Porcelain Strength

- What is low fusing porcelain? Achieve Superior Esthetics and Metal Integrity in PFM Restorations

- What factors are important to consider when choosing a dental sintering furnace? Match Your Workflow for Optimal Results

- How long does it take to make zirconia teeth? From Same-Day to 2 Weeks

- What are the most natural-looking crowns for teeth? Achieve a Seamless, Lifelike Smile

- What is dental ceramic used for? Restore Teeth with Aesthetic, Durable Crowns & Fillings