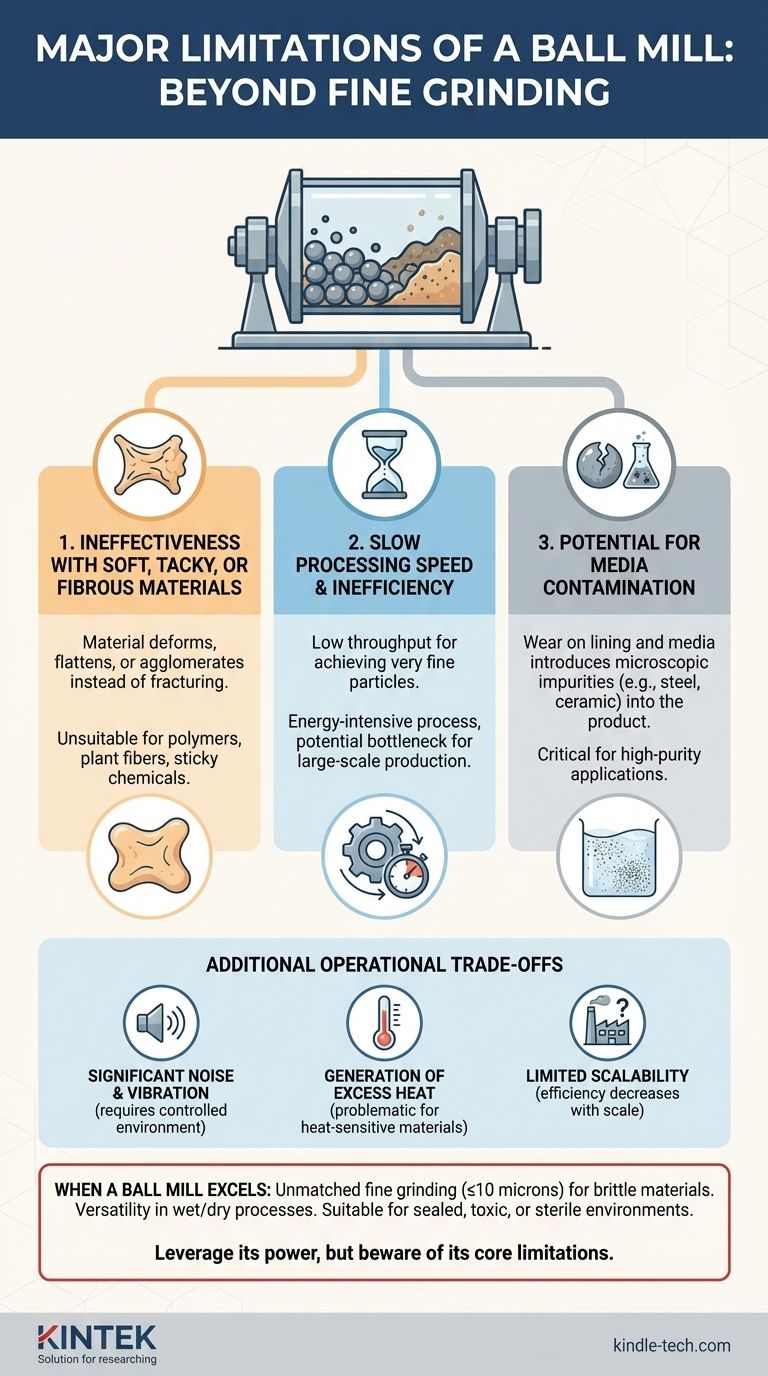

The major limitation of a ball mill is its fundamental ineffectiveness with soft, tacky, or fibrous materials, which tend to deform or agglomerate rather than break down under the mill's impact and attrition forces. This, combined with its slow processing speed and the inherent risk of product contamination from wearing of the grinding media, defines its primary operational boundaries.

While a ball mill is exceptional at producing extremely fine powders from brittle substances, its core limitations are a lack of versatility with certain material types and a slow, energy-intensive process that can introduce impurities into the final product.

The Fundamental Process Limitations

A ball mill's strengths and weaknesses are a direct result of its working principle: crushing material through the repeated impact and attrition of heavy grinding media. This mechanism is highly effective for some applications but creates unavoidable constraints for others.

Ineffectiveness with Soft or Fibrous Materials

A ball mill works by fracturing brittle materials. When faced with soft, elastic, or fibrous substances, the impact from the balls does not cause fracture.

Instead, these materials simply deform, flatten, or clump together. This makes the ball mill entirely unsuitable for applications like grinding plant fibers, soft polymers, or sticky chemicals.

Slow Processing Speed and Inefficiency

The process of reducing particles to a very fine size through random impact and attrition is inherently slow and requires significant time.

This low throughput can be a major bottleneck in large-scale production environments. While the components are simple, achieving the target particle size is often an extended, energy-intensive operation.

Potential for Media Contamination

The constant collision and grinding cause wear on both the internal lining of the mill and the grinding balls themselves.

This wear introduces microscopic particles of the liner or media (e.g., steel, ceramic) into the product. For high-purity applications like pharmaceuticals, advanced ceramics, or food products, this contamination is a critical issue that must be managed with costly, highly abrasion-resistant components.

Understanding the Operational Trade-offs

Beyond the core process limitations, there are several practical trade-offs to consider when operating a ball mill.

Significant Noise and Vibration

The cascading and tumbling of heavy steel or ceramic balls inside a metal drum produces substantial noise and vibration.

This necessitates a controlled environment, proper machine mounting, and hearing protection for operators, adding to the overall operational complexity.

Generation of Excess Heat

The friction and impact from the grinding process generate a significant amount of heat within the milling chamber.

This can be problematic for heat-sensitive materials, potentially causing melting, chemical degradation, or changes in the material's properties.

Limited Scalability for Bulk Processing

While ball mills come in many sizes, their efficiency tends to decrease as the scale increases.

They are often less practical for extremely high-volume, continuous processing compared to other milling technologies, as the time required for a batch can be extensive.

When a Ball Mill Excels

Despite its limitations, a ball mill is the superior choice for specific goals where its unique capabilities are required.

Unmatched Fine Grinding Capability

The primary advantage of a ball mill is its ability to produce extremely fine and consistent powders, often with a particle size of 10 microns or less. For applications requiring nano-sized particles, it remains a go-to technology.

Versatility in Hard Materials and Processes

Ball mills can handle very hard and abrasive materials that would quickly wear out other types of grinders. They are also adaptable to both wet and dry grinding processes, allowing for flexibility in formulation.

Suitability for Sealed Environments

Because the grinding occurs within a sealed container, ball mills are ideal for processing toxic materials without exposing operators. This also allows for sterile processing, which is crucial in the manufacturing of certain pharmaceutical products.

Making the Right Choice for Your Goal

To determine if a ball mill is the correct tool, you must weigh its exceptional grinding power against its significant limitations.

- If your primary focus is achieving the finest particle size with hard, brittle materials: A ball mill is an excellent choice, but you must account for slow processing times and potential contamination.

- If your primary focus is processing soft, tacky, or fibrous materials: A ball mill is fundamentally unsuitable, and you should investigate alternative methods like cutter or knife mills.

- If your primary focus is maintaining absolute product purity: You must carefully select the grinding media and liner material to minimize wear, or accept that contamination is a factor.

- If your primary focus is high-throughput industrial production: A ball mill's slow speed may create a bottleneck, requiring you to consider larger-scale or different types of milling equipment.

Understanding these core limitations allows you to leverage the ball mill's power for the right applications and avoid costly process mismatches.

Summary Table:

| Limitation | Key Impact |

|---|---|

| Ineffective with Soft/Fibrous Materials | Materials deform or clump instead of fracturing. |

| Slow Processing Speed | Low throughput; energy-intensive operation. |

| Risk of Media Contamination | Wear introduces impurities into the final product. |

| Significant Noise & Heat | Requires controlled environment; unsuitable for heat-sensitive materials. |

Struggling with material limitations or contamination in your milling process? KINTEK specializes in lab equipment and consumables, offering solutions tailored to your specific material and purity requirements. Let our experts help you select the right milling technology to enhance your lab's efficiency and product quality. Contact us today for a personalized consultation!

Visual Guide

Related Products

- Stainless Steel Laboratory Ball Mill for Dry Powder and Liquid with Ceramic Polyurethane Lining

- Laboratory Ball Mill Jar Mill with Metal Alloy Grinding Jar and Balls

- Laboratory Single Horizontal Jar Mill

- Laboratory Planetary Ball Mill Rotating Ball Milling Machine

- Laboratory Four-Body Horizontal Jar Mill

People Also Ask

- What is the function of a planetary ball mill for B4C–W powders? Optimize Homogeneity & Sintering Quality

- What is the core role of a high-energy planetary ball mill? Powering Sulfide Solid-State Electrolyte Synthesis

- What is the function of a high-energy ball mill in the preparation of nanoparticle-reinforced steel? | KINTEK

- What is the primary function of a planetary ball mill for sulfide solid electrolytes? Achieve High-Energy Synthesis

- What is the primary function of a planetary ball mill in FeCrAl-based powder prep? Achieve High-Energy Mechanical Alloying

- What are the advantages of high-energy ball milling for COF synthesis? Achieve Rapid, Scalable, & Solvent-Free Results

- What is the primary function of a planetary ball mill for LGPS preparation? Unlock High-Energy Mechanochemical Synthesis

- Why is ball milling equipment with inert atmosphere protection necessary? Preserve Sulfur-based Cathode Integrity