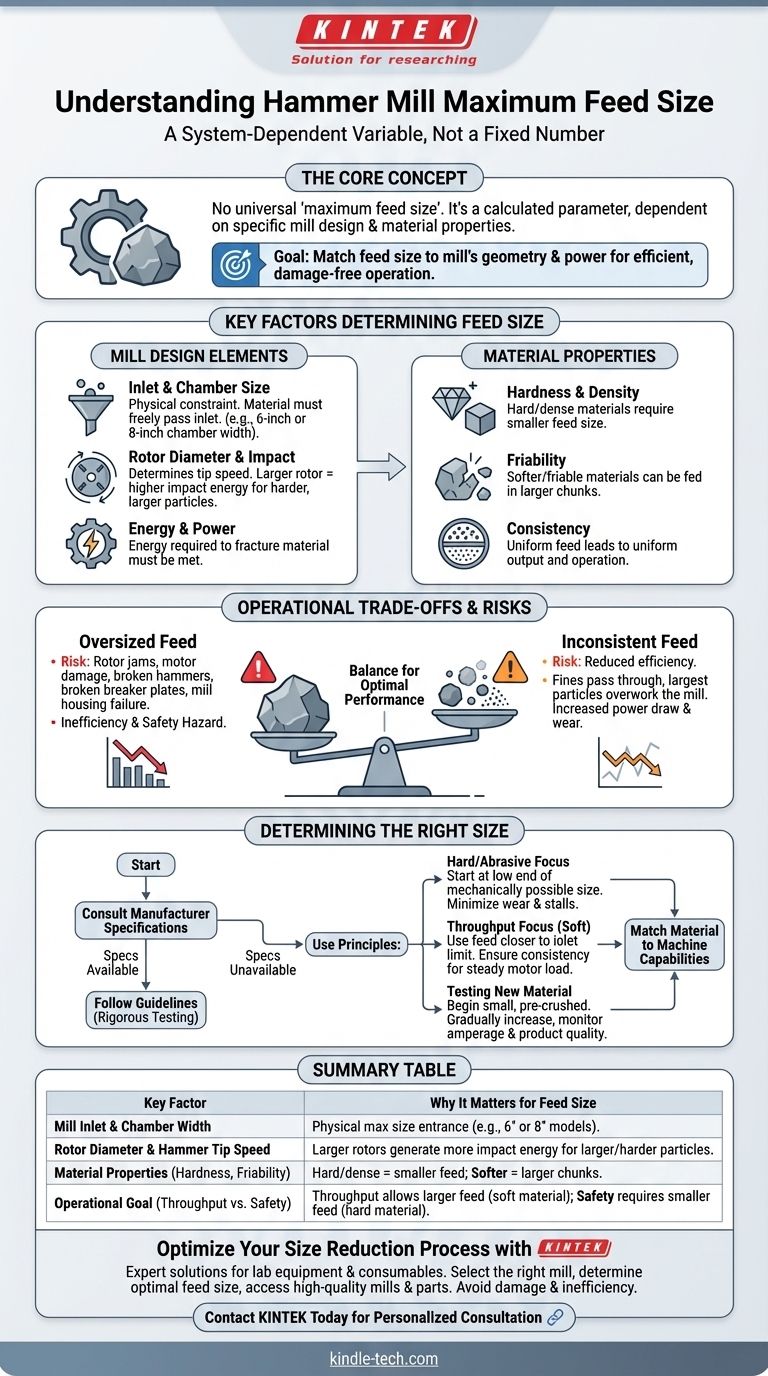

There is no single "maximum feed size" for a hammer mill. This value is not a universal specification but a calculated parameter that depends entirely on the specific design of the mill and the physical properties of the material being processed. The acceptable feed size is ultimately dictated by a combination of factors, including the mill's chamber width, rotor diameter, and the energy required to fracture the material.

The maximum feed size for any given hammer mill is a system-dependent variable, not a fixed number. It must be smaller than the mill's inlet and appropriately matched to its internal geometry and power to prevent mechanical damage and ensure efficient operation.

Why Feed Size Is a System-Dependent Variable

A hammer mill operates by striking material with hammers rotating at high velocity. The "right" feed size is one that allows this process to happen effectively and repeatedly without overwhelming the system. Several key design elements determine this.

The Mill's Inlet and Chamber Size

The most fundamental constraint is physical access. The feed material must be small enough to pass freely through the inlet chute and into the grinding chamber.

This is why hammer mills are often described by their chamber width, such as 6-inch or 8-inch models. This dimension provides a rough indicator of the mill's capacity and the general scale of material it can handle.

Rotor Diameter and Hammer Impact

The rotor is the central assembly that spins the hammers. Its diameter is critical because it determines the tip speed of the hammers for a given rotational speed (RPM).

A larger rotor diameter generates higher impact energy, which is necessary to shatter larger and harder particles on the first strike. Mills designed for coarse, hard materials typically have larger, heavier rotors.

The Properties of Your Material

The characteristics of the feed material itself are just as important as the mill's design. You must consider its hardness, density, and friability (how easily it breaks).

Hard, dense rock requires a much smaller feed size relative to the mill's capacity. Softer, more friable materials like grains or biomass can be fed in larger chunks because they require less energy to break apart.

Understanding the Operational Trade-offs

Selecting the correct feed size is a balance between maximizing throughput and ensuring safe, sustainable operation. Misjudging this parameter leads to predictable problems.

The Risk of Oversized Feed

Introducing material that is too large for the mill is the most common cause of operational failure. This can cause the rotor to jam, leading to catastrophic stalls that can damage the motor.

In severe cases, oversized feed can break the hammers, damage the internal breaker plates, or even compromise the integrity of the mill's housing. It creates extreme inefficiency and poses a significant safety risk.

The Inefficiency of Inconsistent Feed

Optimal performance requires a relatively consistent feed size. A feed stock with a wide distribution—containing both large chunks and very fine particles—can reduce efficiency.

The fines may pass through the screen without sufficient impact, while the largest particles overwork the mill, increasing power draw and wear. Uniformity in the feed leads to uniformity in the output and operation.

How to Determine the Right Feed Size for Your Mill

The most reliable path is to consult the manufacturer's specification sheet for your specific model. They provide operational guidelines based on rigorous design and testing. If specifications are unavailable, use the following principles.

- If your primary focus is processing hard, abrasive materials: Start with a feed size at the very low end of what seems mechanically possible to minimize wear and prevent stalls.

- If your primary focus is maximizing throughput with softer materials: You can use a feed size closer to the upper physical limit of the inlet, but ensure it is consistent to maintain steady motor load.

- If you are testing a new material: Begin with a small, pre-crushed feed and gradually increase the size while carefully monitoring the mill's motor amperage and the quality of the final product.

Ultimately, matching your material to your machine's capabilities is the key to safe, efficient, and effective size reduction.

Summary Table:

| Key Factor | Why It Matters for Feed Size |

|---|---|

| Mill Inlet & Chamber Width | Determines the physical maximum size that can enter the mill (e.g., 6" or 8" models). |

| Rotor Diameter & Hammer Tip Speed | Larger rotors generate more impact energy, allowing for the processing of larger, harder particles. |

| Material Properties (Hardness, Friability) | Hard, dense materials require a smaller feed size; softer materials can be fed in larger chunks. |

| Operational Goal (Throughput vs. Safety) | Maximizing throughput with soft materials allows for larger feed, while safety with hard materials requires smaller feed. |

Optimize Your Size Reduction Process with KINTEK

Selecting the correct hammer mill and feed size is critical for the safety and efficiency of your laboratory or production line. Incorrect sizing can lead to equipment damage, inconsistent results, and costly downtime.

KINTEK specializes in lab equipment and consumables, providing expert solutions for all your size reduction needs. We can help you:

- Select the right hammer mill for your specific material and throughput requirements.

- Determine the optimal feed size to maximize efficiency and protect your investment.

- Access a full range of high-quality mills and replacement parts to keep your operations running smoothly.

Don't risk damage or inefficiency. Let our experts guide you to the perfect solution.

Contact KINTEK today for a personalized consultation!

Visual Guide

Related Products

- Laboratory Single Horizontal Jar Mill

- Laboratory Horizontal Planetary Ball Mill Milling Machine

- High-Energy Omnidirectional Planetary Ball Mill Milling Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Machine for Laboratory

- High Energy Planetary Ball Mill Milling Machine for Laboratory

People Also Ask

- Why use zirconia ball milling jars for SiC/ZTA composite powders? Ensure High Purity & Efficient Particle Refinement

- Why are silicon nitride or zirconia preferred for milling iodo-vanadate-lead precursors? Ensure High Purity Results

- What is the benefit of using tungsten carbide (WC) milling jars and balls? Achieve High-Energy Milling Efficiency

- Why are tungsten carbide grinding jars and balls preferred for high-purity lithium ceramic powders? Ensure Peak Purity.

- How do stainless steel grinding jars and balls contribute to mechanical alloying? Optimize HEA Powder Synthesis