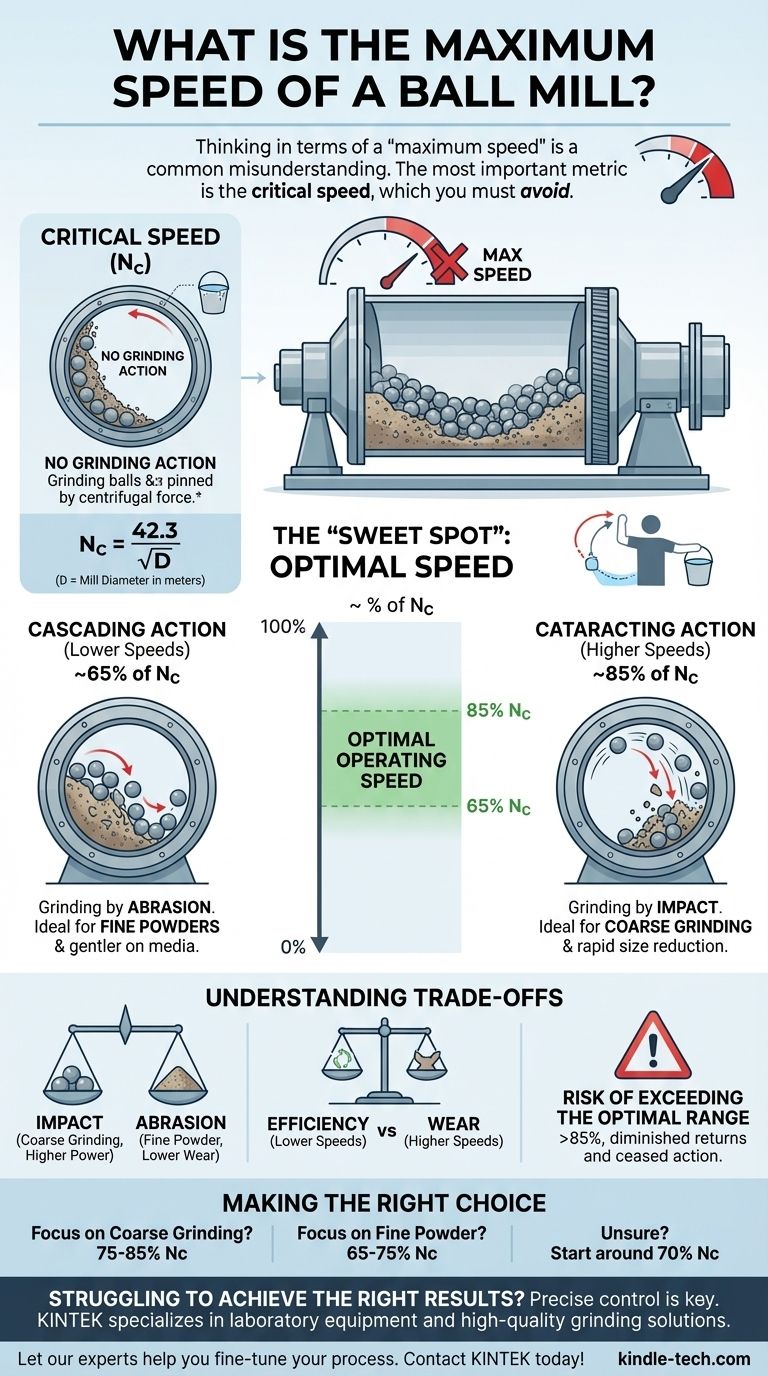

Thinking in terms of a "maximum speed" for a ball mill is a common misunderstanding. The most important metric is the critical speed, which is the theoretical speed you must avoid. At this speed, centrifugal force pins the grinding media to the mill's inner wall, and all grinding action stops completely.

The goal is not to reach a maximum speed, but to find the optimal speed. This is always a specific percentage of the theoretical critical speed, chosen to create the ideal balance of impact and abrasion for your specific material.

What is Critical Speed and Why Does It Matter?

Understanding the concept of critical speed is the foundation for operating any ball mill effectively. It is the boundary between productive work and zero output.

Defining Critical Speed

Critical speed (Nc) is the rotational speed where the centrifugal force acting on the grinding media equals the force of gravity.

Imagine swinging a bucket of water over your head. If you swing it fast enough, the water stays in the bucket. In a ball mill, this is the point where the balls and material get stuck to the liner for the entire rotation.

When this happens, there is no tumbling, no impact, and no grinding. The charge is simply carried around in a circle, consuming energy with no result.

The "Sweet Spot": The Operating Speed

The effective working speed of a ball mill is never 100% of the critical speed. Instead, it is a carefully selected percentage of it.

The industry standard is to operate a ball mill between 65% and 85% of its calculated critical speed. This range ensures the grinding media is lifted high enough to create a powerful grinding action without being pinned to the wall.

Calculating Your Mill's Critical Speed

You can calculate the theoretical critical speed for your mill with a standard formula:

Nc = 42.3 / √D

Here, Nc is the critical speed in revolutions per minute (RPM), and D is the internal diameter of the mill in meters.

Finding the Optimal Grinding Action

The speed you choose directly dictates the type of grinding that occurs inside the mill. There are two primary modes of action you are trying to control.

Cascading Action (Lower Speeds)

At lower speeds (around 65% of critical), the balls tumble over one another in a cascading motion. This action is dominated by abrasion, or the rubbing and scouring of particles between the media.

This is ideal for applications requiring a very fine final product and is gentler on the grinding media.

Cataracting Action (Higher Speeds)

At higher speeds (closer to 85% of critical), the balls are thrown further up the mill wall before detaching and crashing down onto the material at the bottom. This is called cataracting.

This action is dominated by impact, which is excellent for breaking down coarser particles and achieving rapid size reduction.

Understanding the Trade-offs

Choosing your operating speed is a balance between your desired outcome, energy efficiency, and equipment wear.

Impact vs. Abrasion

The core trade-off is between impact and abrasion. Higher speeds favor impact, breaking large pieces quickly. Lower speeds favor abrasion, polishing particles into a finer powder.

Efficiency vs. Wear

Operating at higher speeds in the cataracting range consumes more power and causes greater wear on both the grinding media and the mill liners due to the constant, heavy impacts.

The Risk of Exceeding the Optimal Range

Pushing the speed beyond about 85% of critical yields diminishing returns. The grinding media spends too much time in the air, reducing the number of impacts per minute. As you approach 100%, the grinding action ceases entirely.

Making the Right Choice for Your Goal

Use the concept of critical speed to precisely control your grinding process. Once you have calculated the theoretical critical speed for your mill, you can set the operating speed to match your goal.

- If your primary focus is coarse grinding or rapid size reduction: Operate at the higher end of the optimal range, around 75-85% of the critical speed, to maximize impact forces.

- If your primary focus is producing a very fine powder or minimizing media wear: Operate at the lower end, around 65-75% of the critical speed, to favor abrasion.

- If you are processing a mixed feed or are unsure: Start your process around 70% of the critical speed and adjust based on the results.

Controlling your mill's speed relative to its critical speed is the key to unlocking consistent, efficient, and predictable results.

Summary Table:

| Key Concept | Description | Typical Range |

|---|---|---|

| Critical Speed (Nc) | Speed where grinding stops due to centrifugal force. | Formula: Nc = 42.3 / √D (D = mill diameter in meters) |

| Optimal Operating Speed | The effective working speed for grinding. | 65% - 85% of Critical Speed |

| Cascading Action | Grinding by abrasion; ideal for fine powders. | ~65% of Nc |

| Cataracting Action | Grinding by impact; ideal for coarse grinding. | ~85% of Nc |

Struggling to achieve the right particle size or maximize your mill's efficiency?

The precise control of your ball mill's speed is critical to your results. At KINTEK, we specialize in laboratory equipment and consumables, providing the expertise and high-quality grinding solutions you need to optimize your processes. Whether you're developing new materials or conducting routine analysis, we can help you select the right equipment and settings for your specific application.

Let our experts help you fine-tune your grinding process for superior consistency and yield. Contact KINTEK today to discuss your laboratory needs!

Visual Guide

Related Products

- Stainless Steel Laboratory Ball Mill for Dry Powder and Liquid with Ceramic Polyurethane Lining

- Laboratory Ball Mill Jar Mill with Metal Alloy Grinding Jar and Balls

- High-Energy Omnidirectional Planetary Ball Mill Milling Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Machine for Laboratory

- High Energy Planetary Ball Mill Milling Machine for Laboratory

People Also Ask

- What are the limitations of a ball mill? Key Drawbacks in Efficiency and Purity

- Why are zirconia grinding balls and jars preferred for the ultrafine grinding of eggshells? Ensure Sample Purity

- Why is high-purity argon gas required during vibratory milling of Fe-Cr-Al alloys? Ensure Material Purity

- What function does a high-speed rotor-stator homogenizer perform in biomass processing? Optimize Structural Disruption

- What is the particle size for XRD analysis? Optimize Your Results with the Right Preparation

- What is a ball mill used in pharmaceutical industry? Achieve Superior Particle Size Reduction for Drug Efficacy

- How does the use of grinding equipment benefit iron-substituted manganese oxide? Optimize Energy Storage Performance

- What are the uses of colloid mill in pharmaceutical industry? Achieve Superior Particle Size Reduction and Homogenization