At its core, a ball mill is a mechanical system designed to reduce the size of materials through impact and abrasion. Its design consists of a rotating hollow cylindrical shell mounted on a frame, partially filled with grinding media (balls). The key mechanical components are the shell itself, the abrasion-resistant liners on its inner surface, and the grinding media that performs the work.

The mechanical design of a ball mill is not merely a container that tumbles rocks; it is a precisely engineered system where the shell's rotation converts energy into grinding force through the controlled motion of internal media. Every component, from the shell's dimensions to the liner's profile, is chosen to optimize this energy transfer for a specific size-reduction task.

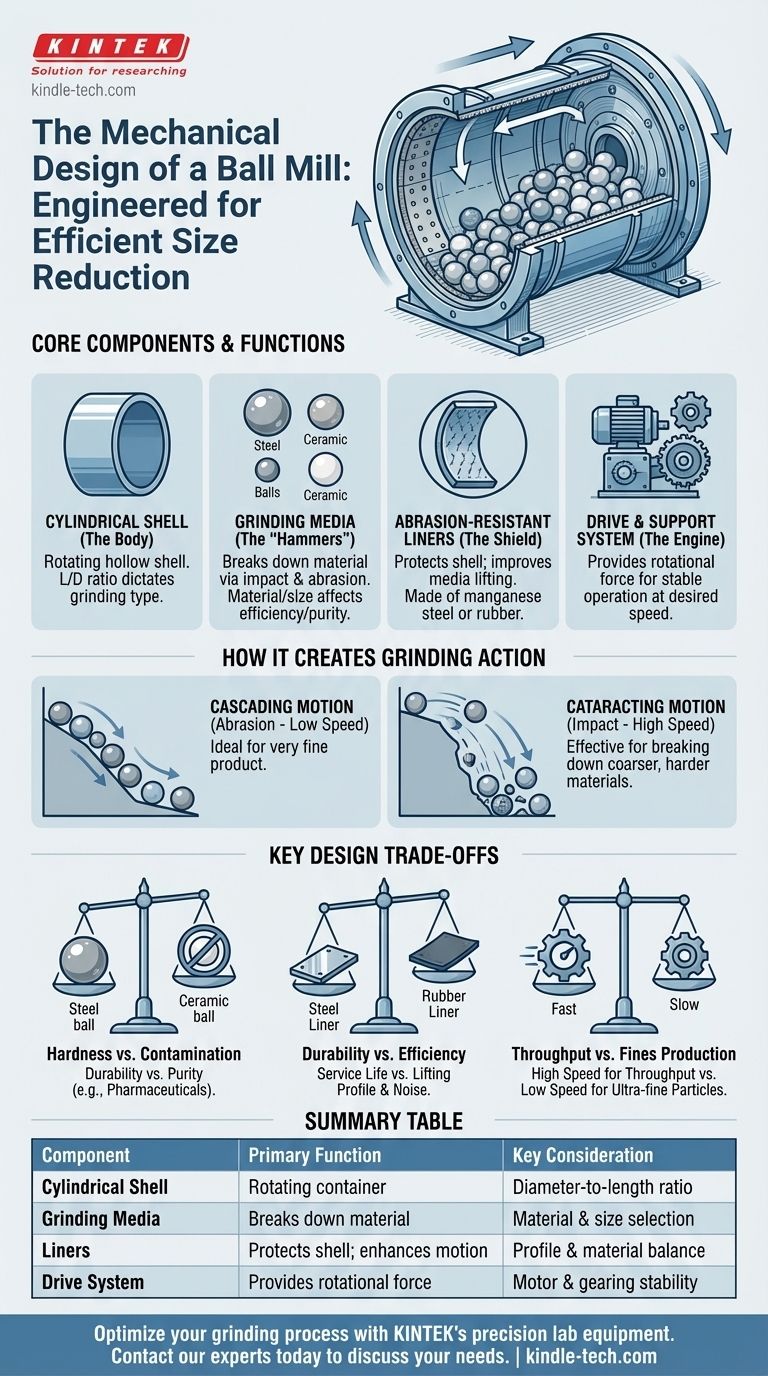

The Core Components and Their Function

Understanding the ball mill requires looking at each primary mechanical part and its specific role in the grinding circuit.

The Cylindrical Shell (The Body)

The shell is the main structural component of the mill. It is a hollow cylinder, typically made of steel, that contains both the material to be ground (the charge) and the grinding media.

The shell is mounted on bearings that allow it to rotate smoothly about its longitudinal axis. Its dimensions—specifically the ratio of its diameter to its length—are critical design parameters that influence the type of grinding that occurs.

Grinding Media (The "Hammers")

The grinding media are the active components responsible for breaking down the material. These are typically spherical balls, though other shapes can be used.

The media are selected based on the application. Steel or stainless steel balls are used for their high impact force and durability in mineral processing, while ceramic balls are chosen for applications where avoiding iron contamination is critical. A mix of large and small balls is often used; large balls break down coarse feed, while smaller balls fill the gaps to create finer product.

Abrasion-Resistant Liners (The Shield)

The inner surface of the shell is protected by liners. Without them, the constant impact and abrasion from the media and charge would quickly destroy the shell.

These liners are made from highly durable materials like manganese steel or specialized rubber compounds. Beyond protection, the profile of the liners (e.g., wave or step patterns) is designed to help lift the grinding media as the shell rotates, improving the grinding action.

The Drive and Support System (The Engine)

This system provides the rotational force. It typically consists of a large motor connected to a gearbox that turns a pinion gear. This pinion engages with a large ring gear mounted on the outside of the shell, causing the entire cylinder to rotate.

The entire assembly is supported on a robust metallic frame, ensuring stability and proper alignment during operation.

How Mechanical Design Creates the Grinding Action

The effectiveness of a ball mill comes from how its mechanical design manipulates physics to create two primary grinding forces. The speed of rotation, a key design parameter, determines which force dominates.

Cascading Motion (Abrasion)

At lower rotational speeds, the grinding media are lifted up the side of the shell and then gently tumble back down over the rest of the charge. This creates a rubbing and abrasive action, ideal for achieving a very fine final product.

Cataracting Motion (Impact)

At higher rotational speeds (but below the "critical speed" where media would centrifuge), the balls are thrown across the diameter of the mill. They crash down onto the material at the bottom, creating a high-impact force that is effective for breaking down coarser, harder materials.

Understanding Key Design Trade-offs

The selection of each mechanical component involves balancing performance, cost, and operational life.

Grinding Media: Hardness vs. Contamination

Using hardened steel media provides maximum impact and wear resistance, which is essential for grinding hard ores. However, this introduces slow but steady iron contamination into the product, which is unacceptable in industries like pharmaceuticals or high-purity ceramics.

Liners: Durability vs. Grinding Efficiency

Manganese steel liners offer exceptional service life but are heavy and can be costly. Rubber liners are lighter, reduce noise, and can sometimes provide a better lifting profile for the media, but they are not suitable for all applications, particularly those with very sharp materials or high temperatures.

Mill Speed: Throughput vs. Fines Production

Operating the mill at a higher speed to induce cataracting can increase throughput by breaking down coarse particles quickly. However, this high-impact action is less efficient at producing the ultra-fine particles that are best achieved through the slower, abrasive cascading motion.

Matching the Design to Your Milling Goal

The mechanical configuration of a ball mill should be directly aligned with its intended purpose.

- If your primary focus is coarse, high-impact grinding: The design should favor a larger-diameter mill with steel media and aggressive lifter-bar-style liners to promote cataracting motion.

- If your primary focus is fine, abrasive grinding: The optimal design is often a longer mill with a large charge of smaller ceramic or steel media, operated at a lower speed to ensure a consistent cascading action.

- If your primary focus is avoiding product contamination: The only choice is non-metallic components, such as ceramic grinding media and ceramic or specialized polymer-based liners.

Ultimately, a ball mill's mechanical design is a unified system where every part works together to transform rotational energy into the precise forces needed for material size reduction.

Summary Table:

| Component | Primary Function | Key Considerations |

|---|---|---|

| Cylindrical Shell | Rotating container for material and media | Diameter-to-length ratio dictates grinding type |

| Grinding Media | Breaks down material via impact/abrasion | Material (steel/ceramic) and size affect efficiency/contamination |

| Liners | Protects shell; enhances media motion | Profile and material (steel/rubber) balance durability and performance |

| Drive System | Provides rotational force | Motor and gearing ensure stable operation at desired speed |

Optimize your grinding process with KINTEK's precision lab equipment. Whether you need coarse impact grinding or fine abrasive milling, our ball mills and consumables are engineered for your specific application—from mineral processing to high-purity ceramics. Contact our experts today to discuss your laboratory needs and achieve superior size reduction results.

Visual Guide

Related Products

- High Energy Planetary Ball Mill Machine for Laboratory Horizontal Tank Type

- Mini Planetary Ball Mill Machine for Laboratory Milling

- Liquid Nitrogen Cryogenic Grinder Mill Cryomill Airflow Ultrafine Pulverizer

- Powerful Plastic Crusher Machine

- Laboratory Test Sieves and Vibratory Sieve Shaker Machine

People Also Ask

- What is the role of a planetary ball mill in the preparation of NiCr-Al2O3-SrCO3 composite powders? Enhanced Homogeneity

- What is the specific role of a high-energy planetary ball mill in the synthesis of Ag-doped sulfide solid-state electrolytes?

- Why is a high-energy planetary ball mill preferred over traditional casting for nanocrystalline HEAs?

- What is the role of a planetary ball mill in the synthesis of Li2S–P2S5 sulfide solid-state electrolytes?

- What is the function of a high-energy planetary ball mill in the synthesis of iodo-vanadate-lead ceramic waste forms?