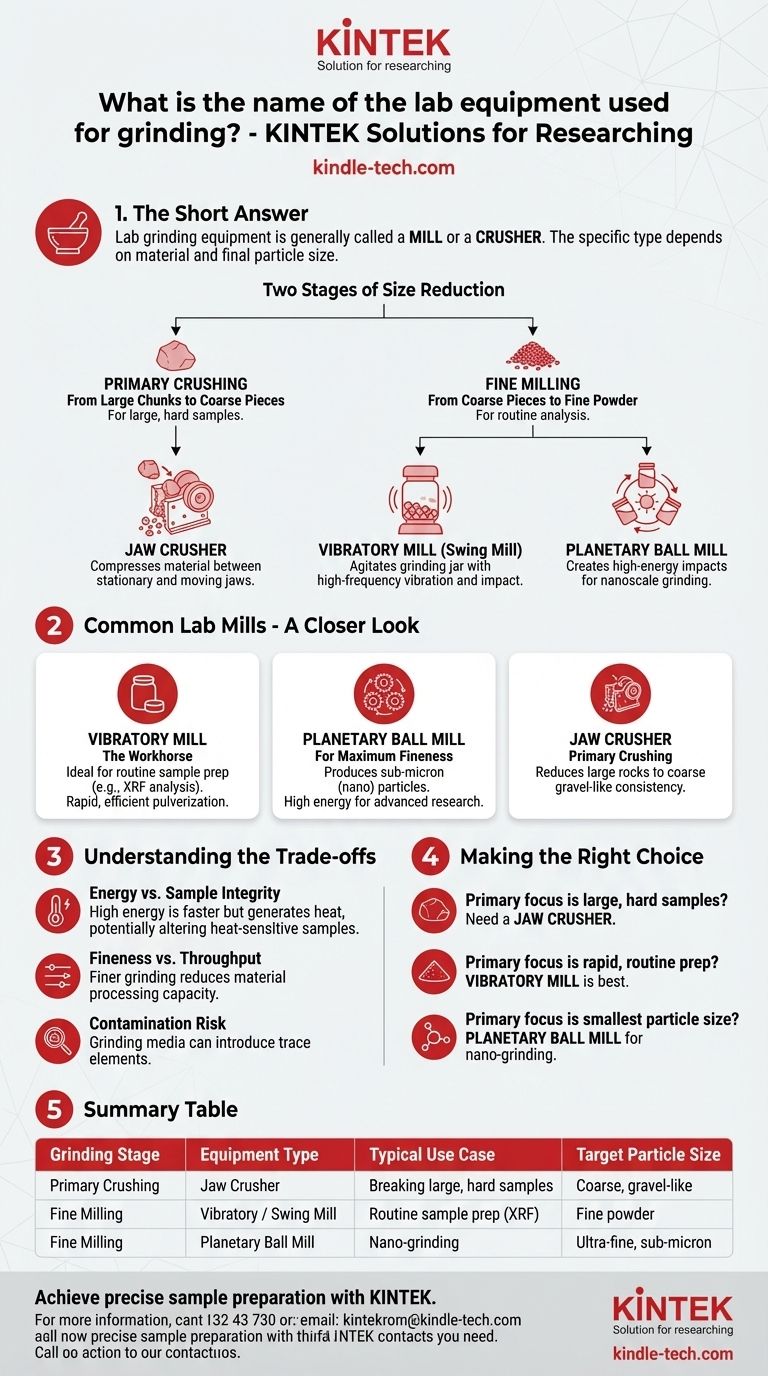

The short answer is that laboratory equipment for grinding is generally called a mill or a crusher. The specific name depends entirely on the material you are working with and the final particle size you need. Common examples include jaw crushers for coarse breaking and vibratory, swing, or planetary mills for producing fine powders.

The key is to understand that "grinding" involves two distinct stages: coarse crushing and fine milling. Choosing the right equipment means matching the machine's mechanism to your starting material and your target particle size.

The Two Stages of Size Reduction: Crushing vs. Milling

Before selecting a tool, you must first identify your objective. Are you breaking down a large, solid rock, or are you turning a small, granular sample into a superfine powder? These are two different jobs requiring two different types of equipment.

Primary Crushing: From Large Chunks to Coarse Pieces

The first step for large, hard, and brittle samples is crushing. This stage takes large pieces and reduces them to a coarse, gravel-like consistency suitable for further processing.

The primary tool for this is the jaw crusher. It works by compressing material between a stationary jaw and a moving jaw, fracturing the sample through immense pressure.

Fine Milling: From Coarse Pieces to Fine Powder

Once a sample is crushed to a manageable size (typically a few millimeters), the next step is milling. This is the process most people think of as "grinding," where coarse particles are reduced to a fine or ultra-fine powder for analysis.

Milling equipment uses mechanisms like impact, friction, and shearing to achieve this fine size reduction. This is where tools like vibratory and planetary mills come into play.

A Closer Look at Common Laboratory Mills

For most sample preparation tasks, a mill is the correct instrument. However, different mills operate on different principles and are suited for different outcomes.

The Vibratory Mill (or Swing Mill): The Workhorse

A vibratory mill is the most common piece of grinding equipment in analytical labs. It agitates a grinding jar containing the sample and one or more grinding media (like balls or a puck and ring) at high frequency.

This rapid vibration and impact pulverizes the sample quickly and efficiently. These mills are ideal for routine sample preparation for techniques like X-Ray Fluorescence (XRF) and are available in various sizes to handle different sample volumes.

The Planetary Ball Mill: For Maximum Fineness

For applications requiring extremely small particle sizes, a planetary ball mill is the superior choice. This device places grinding jars on a large rotating "sun wheel." The jars themselves also rotate, but in the opposite direction.

This combined motion creates extremely high-energy impacts between the grinding balls and the sample, enabling nanoscale grinding (producing particles smaller than 1 micron). This power makes it ideal for materials science research, mechanical alloying, and colloid preparation.

Understanding the Trade-offs

Selecting a grinding method is not just about the final particle size; it involves balancing several competing factors.

Energy vs. Sample Integrity

Higher-energy milling (like in a planetary mill) produces finer particles faster. However, this high energy can generate significant heat, which may alter heat-sensitive samples or cause phase transformations.

Fineness vs. Throughput

There is a direct trade-off between how fine you can grind and how much material you can process. A jaw crusher can process many kilograms per hour but only produces coarse material. A planetary mill creates nano-sized particles but typically handles only a few grams at a time.

Contamination Risk

All grinding introduces a small amount of contamination from the grinding media (jars and balls). Harder samples require harder grinding media (like tungsten carbide), which can be a source of contamination if your subsequent analysis is sensitive to those elements.

Making the Right Choice for Your Goal

To select the correct equipment, define your primary objective.

- If your primary focus is pre-crushing large, hard samples like rocks or ores: You need a Jaw Crusher for primary size reduction.

- If your primary focus is rapid, routine preparation of samples for chemical analysis: A Vibratory Mill (or Swing Mill) offers the best balance of speed and fineness.

- If your primary focus is achieving the smallest possible particle size for advanced research: A Planetary Ball Mill provides the high energy required for nano-grinding.

Ultimately, successful sample preparation comes from matching the grinding principle to your specific material and analytical goals.

Summary Table:

| Grinding Stage | Equipment Type | Typical Use Case | Target Particle Size |

|---|---|---|---|

| Primary Crushing | Jaw Crusher | Breaking large, hard samples (rocks, ores) | Coarse, gravel-like |

| Fine Milling | Vibratory / Swing Mill | Routine sample prep for XRF analysis | Fine powder |

| Fine Milling | Planetary Ball Mill | Nano-grinding for advanced research | Ultra-fine, sub-micron particles |

Achieve precise and contamination-free sample preparation with the right grinding equipment from KINTEK.

Whether you are crushing large rocks for primary analysis or milling materials to a nanoscale for advanced research, selecting the correct mill is critical for your results. KINTEK specializes in providing high-quality laboratory jaw crushers, vibratory mills, and planetary ball mills tailored to your specific material and particle size requirements.

Our experts can help you navigate the trade-offs between fineness, throughput, and sample integrity to enhance your lab's efficiency and accuracy.

Contact our team today to discuss your application and find the perfect grinding solution for your laboratory needs.

Visual Guide

Related Products

- Laboratory Single Horizontal Jar Mill

- High Energy Vibratory Laboratory Ball Mill Double Tank Type

- Laboratory Horizontal Planetary Ball Mill Milling Machine

- High Energy Planetary Ball Mill Milling Machine for Laboratory

- High Energy Planetary Ball Mill Milling Machine for Laboratory

People Also Ask

- Why are silicon nitride or zirconia preferred for milling iodo-vanadate-lead precursors? Ensure High Purity Results

- Why are excellent sealing and corrosion resistance required for WC-10Co ball milling? Ensure High-Purity Mixing Results

- What are the advantages of polyurethane ball mill jars for silicon nitride? Ensure Purity & Prevent Metal Contamination

- What is the ball mill based on the principle of? Impact and Attrition for Efficient Grinding

- Why are tungsten carbide grinding jars and balls preferred for high-purity lithium ceramic powders? Ensure Peak Purity.