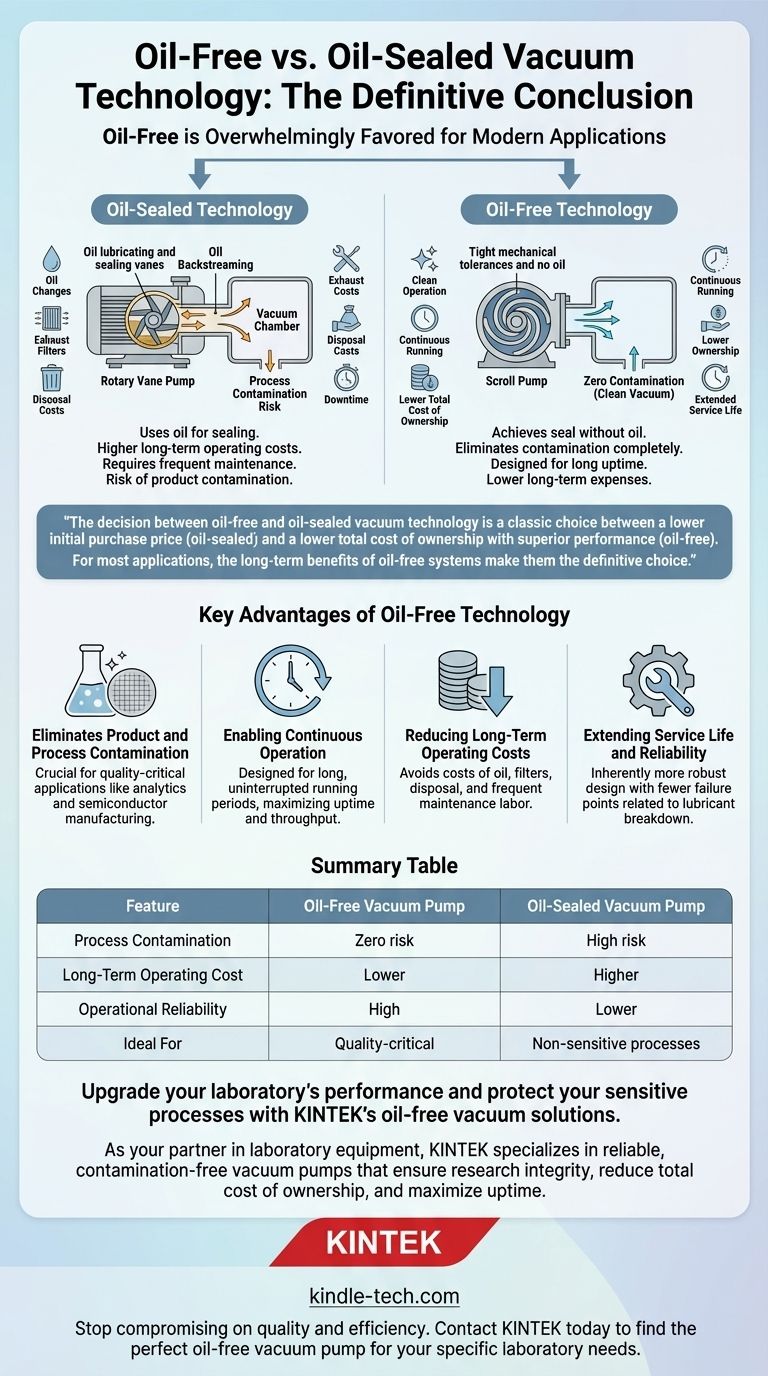

In modern vacuum applications, oil-free technology is overwhelmingly favored over traditional oil-sealed systems. The primary reasons for this shift are the complete elimination of process contamination, significantly lower long-term operating costs, and enhanced operational reliability. While oil-sealed pumps have niche uses, their disadvantages in maintenance and cleanliness make them a liability for most quality-critical processes.

The decision between oil-free and oil-sealed vacuum technology is a classic choice between a lower initial purchase price (oil-sealed) and a lower total cost of ownership with superior performance (oil-free). For most applications, the long-term benefits of oil-free systems make them the definitive choice.

The Fundamental Difference: Sealing and Contamination

To understand the comparison, you must first grasp how each technology creates a vacuum. The core difference lies in the substance used to seal the moving parts of the pump.

How Oil-Sealed Pumps Work

Oil-sealed pumps, most commonly rotary vane pumps, use a thin film of oil to seal the gaps between the rotating vanes and the pump housing. This oil serves as both a sealant and a lubricant.

The inherent drawback is that this oil is exposed to the vacuum. Oil molecules can "backstream" from the pump into the vacuum chamber, contaminating your process, experiment, or product.

How Oil-Free Pumps Work

Oil-free pumps, also called "dry pumps," use alternative engineering to achieve a seal without oil. This includes technologies like scroll pumps, diaphragm pumps, and multi-stage roots pumps.

These designs rely on extremely tight mechanical tolerances or flexible, non-contaminating materials like PTFE to separate the compression stages. This completely isolates the vacuum path from any lubricants.

Key Advantages of Oil-Free Technology

The choice to eliminate oil from the vacuum generation process creates a cascade of operational benefits that directly impact process quality, uptime, and your budget.

Eliminating Product and Process Contamination

This is the single most important benefit. Oil vapor is a significant contaminant that can ruin sensitive analytics, damage optical coatings, or render semiconductor wafers useless.

An oil-free pump provides a clean vacuum, ensuring that the only gases in your system are the ones you intend to be there. This is non-negotiable for fields like mass spectrometry, electron microscopy, and medical device manufacturing.

Enabling Continuous Operation

Oil-sealed pumps require regular maintenance to monitor, change, and top-off oil. This planned downtime reduces equipment availability and productivity.

Oil-free pumps are designed for long, continuous running periods, often operating for thousands of hours before requiring service. This maximizes uptime and throughput.

Reducing Long-Term Operating Costs

While an oil-sealed pump may be cheaper to buy, it is more expensive to own. The total cost of ownership includes the ongoing expense of vacuum pump oil, exhaust filters, and contaminated oil disposal.

Factoring in the labor costs for maintenance and the cost of potential process failures from contamination, the financial argument for oil-free technology becomes clear and compelling.

Extending Service Life and Reliability

Oil in a vacuum pump degrades over time, especially when exposed to heat or reactive process gases. This degraded oil becomes less effective, increasing wear and tear on the pump's internal components.

Oil-free designs are inherently more robust and have fewer failure points related to lubricant breakdown, leading to longer service intervals and a more predictable maintenance schedule.

Understanding the Trade-offs

No technology is perfect for every scenario. Acknowledging the trade-offs is key to making an informed decision.

The Role of Initial Purchase Price

The most common reason for choosing an oil-sealed pump is its lower upfront cost. For labs or projects with tight capital budgets, this can be a tempting advantage.

However, this initial savings is almost always offset by higher long-term operating costs and the risk of contamination, which can be far more expensive than the pump itself.

When Oil-Sealed Pumps Still Have a Place

Oil-sealed pumps remain viable for applications where a clean vacuum is not a priority. This is often limited to "dirty" industrial processes or as roughing pumps for high-vacuum systems where multiple traps are in place to prevent oil backstreaming.

If the process is insensitive to hydrocarbon contamination and the primary goal is simply to remove bulk air, an oil-sealed pump can be a cost-effective, albeit dated, solution.

The Myth of "Maintenance-Free"

It is critical to understand that oil-free is not maintenance-free. All mechanical pumps require eventual service.

For example, a scroll pump will eventually need its tip seals replaced. The key difference is that this maintenance is clean, predictable, and occurs at much longer intervals (often years) compared to the frequent oil changes required by sealed pumps.

How to Choose the Right Vacuum Technology

Your final decision should be guided by the specific requirements of your process and your long-term operational goals.

- If your primary focus is process purity and quality: The choice is unequivocally oil-free technology to eliminate any risk of hydrocarbon contamination.

- If your primary focus is maximizing uptime and reducing maintenance: An oil-free pump will deliver superior reliability and longer service intervals, minimizing costly downtime.

- If your primary focus is the lowest possible initial cost for a non-sensitive application: An oil-sealed pump may be considered, but you must budget for the higher total cost of ownership and accept the inherent contamination risk.

Ultimately, the shift toward oil-free vacuum technology reflects a broader industry commitment to higher quality, greater reliability, and lower long-term operating expense.

Summary Table:

| Feature | Oil-Free Vacuum Pump | Oil-Sealed Vacuum Pump |

|---|---|---|

| Process Contamination | Zero risk of oil backstreaming | High risk of hydrocarbon contamination |

| Long-Term Operating Cost | Lower (no oil, filters, disposal) | Higher (ongoing oil & maintenance costs) |

| Operational Reliability | High (long service intervals) | Lower (frequent oil changes required) |

| Ideal For | Quality-critical processes, analytics, R&D | Non-sensitive, 'dirty' industrial processes |

Upgrade your laboratory's performance and protect your sensitive processes with KINTEK's oil-free vacuum solutions.

As your partner in laboratory equipment, KINTEK specializes in providing reliable, contamination-free vacuum pumps that ensure the integrity of your research and manufacturing. Our oil-free technology eliminates the risk of hydrocarbon contamination, reduces your total cost of ownership, and maximizes uptime—critical for applications in mass spectrometry, electron microscopy, and medical device manufacturing.

Stop compromising on quality and efficiency. Contact KINTEK today to find the perfect oil-free vacuum pump for your specific laboratory needs and experience the KINTEK difference in reliability and support.

Visual Guide

Related Products

- Oil Free Diaphragm Vacuum Pump for Laboratory and Industrial Use

- Circulating Water Vacuum Pump for Laboratory and Industrial Use

- Laboratory Rotary Vane Vacuum Pump for Lab Use

- Electric Heated Hydraulic Vacuum Heat Press for Lab

- 30T 40T Split Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- Why is a water-cooling jacket system necessary in magnesium alloy sublimation refining? Key to Purity and Protection

- What are the advantages of high-purity quartz reaction tubes compared to metal? Ensure Data Integrity in Lab Research

- What is metallographic sandpaper and how should it be used? A Guide to Flawless Sample Preparation

- Why select tungsten carbide grinding balls for chromium & silicon? Maximize Milling Power and Purity

- Why are zirconia grinding balls preferred for Ag-SnO2-Y2O3 milling? Achieve High Purity & Mechanical Efficiency

- Why is a water-cooled copper hearth necessary? Protect Fe-Cu-O Melts from Contamination and Segregation

- What is the function of alumina tubes and alumina wool in a pyrolysis furnace? Optimize Your Biochar Production Quality

- What is a vacuum switch in a furnace? The Essential Safety Guardian for Your Heating System