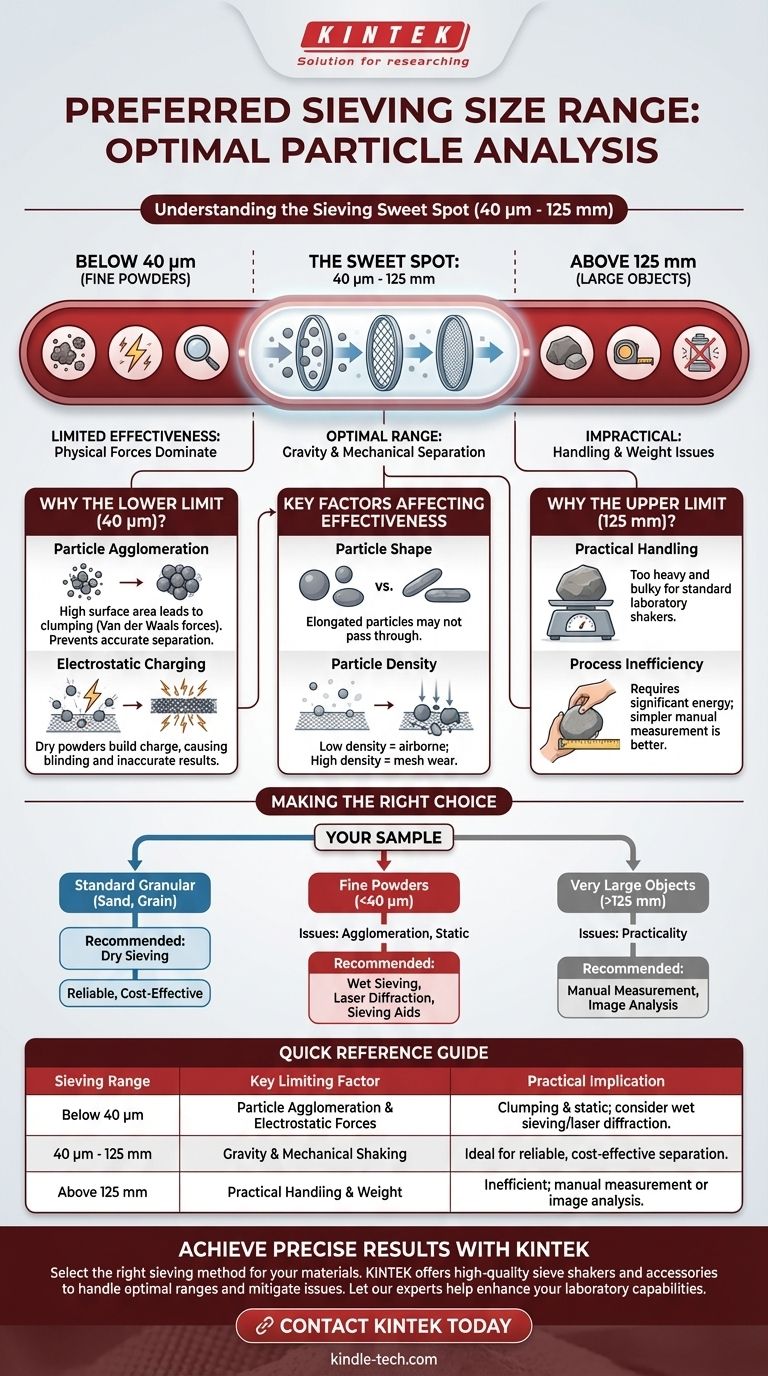

The preferred size range for standard dry sieving is between 40 micrometers (µm) and 125 millimeters (mm). This range represents the sweet spot where mechanical separation of particles by size is both practical and accurate. Outside of these boundaries, the physical principles of sieving begin to break down, leading to unreliable results.

While sieving is a foundational method for particle size analysis, its effectiveness is strictly defined by physical limits. The optimal range exists because particles that are too fine are prone to clumping and electrostatic forces, while particles that are too large make the process impractical.

Why This Range is Optimal

Sieve analysis works by passing a sample through a stack of screens with progressively smaller mesh openings. The effectiveness of this process is directly tied to the physical characteristics of the particles being measured.

The Upper Limit: Practical Handling (125 mm)

The upper boundary of 125 mm (approximately 5 inches) is primarily a matter of practicality.

Particles larger than this are often too heavy and bulky to be efficiently analyzed with standard laboratory shakers. The energy required to move them effectively across a screen becomes substantial, and the process is often replaced by simpler manual measurement.

The Lower Limit: Physical Forces (40 µm)

The 40 µm lower boundary is determined by the physics of fine powders, not the availability of smaller mesh. While sieve mesh is available down to 20 µm, its practical use is limited.

As particles become very fine, forces other than gravity begin to dominate their behavior. This makes it difficult for them to pass through the mesh openings independently, compromising the accuracy of the analysis.

Key Factors That Limit Sieving Effectiveness

Understanding what happens at the lower limit is crucial for accurate particle analysis. Several properties of the sample itself can interfere with the sieving process, especially with fine powders.

Particle Agglomeration

Fine particles have a high surface area-to-volume ratio, making them susceptible to clumping together, or agglomerating.

This can be caused by trace amounts of moisture or weak intermolecular attractions (van der Waals forces). These clumps then behave as larger particles, preventing them from passing through the appropriate sieve and skewing the results toward a coarser distribution.

Electrostatic Charging

During the shaking process, dry, non-conductive powders can develop an electrostatic charge.

This causes particles to repel each other and stick to the sieve frame or the mesh itself. This "blinding" of the screen prevents other particles from passing through and leads to an inaccurate measurement.

Particle Shape and Density

While size is the primary factor, particle shape and density also play a role. Elongated or flat particles may not pass through openings that a spherical particle of the same mass would.

Furthermore, very low-density materials may become airborne in the shaker and fail to make sufficient contact with the mesh, while very high-density particles can cause premature wear or damage to finer screens.

Making the Right Choice for Your Sample

Your decision to use sieving should be based on the nature of your material and the expected particle size range.

- If your primary focus is on standard granular materials (like sand, grain, or aggregates): Dry sieving is the most reliable, cost-effective, and straightforward method available.

- If your primary focus is on fine powders (approaching or below 40 µm): You must account for potential issues like agglomeration and static. Consider using a sieving aid or an alternative method like wet sieving or laser diffraction.

- If your primary focus is on very large objects (above 125 mm): Sieving is impractical. Direct manual measurement or image analysis is a more suitable approach.

Recognizing the operational boundaries of sieving is the first step toward achieving accurate and meaningful particle size data.

Summary Table:

| Sieving Range | Key Limiting Factor | Practical Implication |

|---|---|---|

| Below 40 µm | Particle Agglomeration & Electrostatic Forces | Clumping and static prevent accurate separation; consider wet sieving or laser diffraction. |

| 40 µm - 125 mm | Gravity & Mechanical Shaking | Ideal for reliable, cost-effective separation of standard granular materials. |

| Above 125 mm | Practical Handling & Weight | Sieving becomes inefficient; manual measurement or image analysis is recommended. |

Achieve precise and reliable particle size analysis with the right equipment from KINTEK.

Whether you are working with standard aggregates or challenging fine powders, selecting the correct sieving method is critical for accurate data. KINTEK specializes in high-quality lab equipment, including robust sieve shakers and accessories designed to handle materials within the optimal range and mitigate issues like agglomeration.

Let our experts help you enhance your laboratory's capabilities.

Contact KINTEK today to discuss your specific application and find the perfect sieving solution for your needs.

Visual Guide

Related Products

- Laboratory Test Sieves and Vibratory Sieve Shaker Machine

- Laboratory Vibratory Sieve Shaker Machine for Dry and Wet Three-Dimensional Sieving

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Vibratory Sieve Shaker Machine Dry Three-Dimensional Vibrating Sieve

- Laboratory Vortex Mixer Orbital Shaker Multifunctional Rotation Oscillation Mixer

People Also Ask

- What are the examples of separating mixtures using sieve? From Kitchens to Labs

- What are advantages and disadvantages of sieving method? A Guide to Reliable & Cost-Effective Particle Sizing

- What mixtures can be separated by sieving? A Guide to Efficient Solid-Solid Separation

- What is the importance of sieve analysis test? Unlock Material Performance & Quality Control

- What are the sieve testing standards? A Guide to Accurate Particle Size Analysis

- What is the tool called that is used in the process of sieving? The Essential Guide to Sieves and Particle Separation

- What is the purpose of processing dried Aluminum Nitride mixed powder with a 200-mesh standard sieving system?

- What is the purpose of using a laboratory grinder with specific mesh sieves for oat straw? Optimize Pellet Quality