The fundamental principle of a ball mill is to achieve particle size reduction through mechanical forces generated within a rotating drum. As the drum turns, grinding media—typically heavy steel or ceramic balls—are lifted and then fall, crushing the material caught between them. This process combines high-energy impacts with continuous grinding and shearing forces to break down coarse substances into a fine powder.

A ball mill operates not by random chance, but by the controlled application of two primary forces: impact and attrition. Mastering the balance between these forces by adjusting rotational speed and media size is the key to achieving a specific and consistent final particle size.

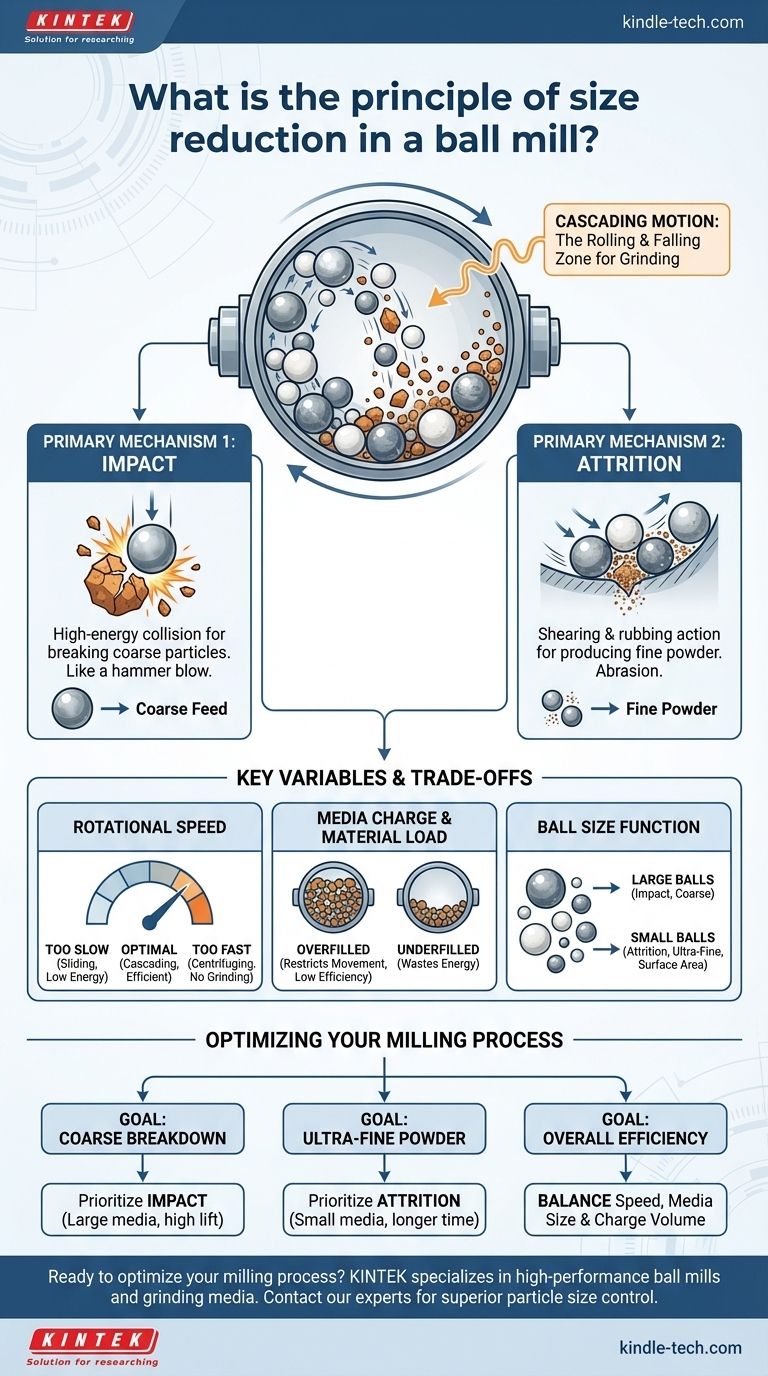

How a Ball Mill Achieves Size Reduction

A ball mill is a simple yet highly effective machine. Its operation relies on the dynamic interaction between the rotating cylinder, the grinding media inside, and the material being processed.

The Role of the Rotating Cylinder

The core of the mill is a hollow cylinder that rotates on its horizontal axis. When material and grinding media are loaded inside, the rotation lifts the contents up the side of the drum. This stored potential energy is the source of the grinding force.

The Grinding Media (The "Balls")

The grinding media are the agents of size reduction. These are typically hard-wearing balls made of materials like high-chromium steel or ceramic. Their purpose is to transfer the kinetic energy from their fall directly onto the target material.

The Importance of Cascading Motion

The effectiveness of the mill depends entirely on how the media moves. As the cylinder rotates, the balls are lifted until gravity overcomes the centrifugal and frictional forces, causing them to tumble and fall back to the bottom of the mill. This continuous, rolling, falling motion is known as cascading. It is within this cascading zone that all the grinding work is done.

The Core Mechanisms of Grinding

Size reduction in a ball mill is not a single action but a combination of two distinct mechanisms that work in tandem. The dominance of each mechanism is determined by the mill's operating parameters.

Impact: For Breaking Coarse Particles

Impact occurs when the grinding balls are lifted high enough to fall directly onto the coarse feed material. This high-energy collision acts like a hammer blow, causing brittle fracture and breaking large pieces into smaller ones. This is the primary mechanism for the initial breakdown of a substance.

Attrition: For Producing Fine Powder

Attrition, also known as abrasion or shearing, is a rubbing and grinding action. It happens as balls slide and roll against each other and against the mill's inner liner, with the target material trapped between them. This shearing force is less intense than impact but is essential for reducing small particles into a very fine powder.

The Function of Different Ball Sizes

The size of the grinding media is a critical variable.

- Large balls possess greater mass and generate higher impact forces, making them ideal for breaking down large, coarse feed.

- Small balls have a greater total surface area and fill the void spaces between larger balls. This increases the probability of attrition and is necessary for producing an ultra-fine final product.

Understanding the Trade-offs

Optimizing a ball mill is a process of managing competing variables. Changing one parameter will inevitably affect others, creating a series of trade-offs.

The Effect of Rotational Speed

Speed is the most critical parameter.

- Too slow: The balls will simply slide or roll up the side of the mill, leading to inefficient grinding dominated by low-energy attrition.

- Too fast: Centrifugal force will pin the balls to the mill's outer wall, preventing them from falling. This is called centrifuging, and at this point, all grinding action ceases.

- Just right: The optimal speed creates a continuous cascade, balancing impact and attrition for the most efficient size reduction.

Media Charge and Material Load

The volume of media and material loaded into the mill (the "charge") is crucial. Overfilling the mill will restrict the movement of the balls, smothering the cascading action and dramatically reducing efficiency. Underfilling it wastes energy as impacts occur between balls or on the mill liner itself.

Wet vs. Dry Grinding

Ball mills can be operated with or without a liquid (typically water). Wet grinding often increases efficiency, reduces energy consumption, and helps control dust. However, it requires a subsequent drying step, adding complexity and cost to the overall process.

Optimizing the Milling Process for Your Goal

Your final objective dictates how you should configure and operate the ball mill. Use these principles as a guide.

- If your primary focus is breaking down large, coarse materials: Prioritize impact forces by using larger grinding media and operating at a speed that ensures the balls are lifted high before falling.

- If your primary focus is producing an ultra-fine powder: Prioritize attrition by using a charge of smaller grinding media and potentially longer milling times to maximize surface-level shearing.

- If your primary focus is overall process efficiency: Carefully balance rotational speed, media size distribution, and charge volume to maintain a consistent cascading motion, avoiding both centrifuging and low-energy sliding.

By understanding these core principles, you can transform the ball mill from a simple grinder into a precise tool for particle engineering.

Summary Table:

| Principle | Mechanism | Key Factors |

|---|---|---|

| Impact | High-energy collision from falling balls | Large ball size, optimal rotational speed |

| Attrition | Shearing/rubbing action between balls | Small ball size, media surface area |

| Cascading Motion | Continuous rolling and falling of media | Correct rotational speed, proper charge volume |

Ready to optimize your milling process for superior particle size control?

At KINTEK, we specialize in providing high-performance ball mills and grinding media tailored to your specific laboratory needs. Whether you require coarse breakdown or ultra-fine powder production, our experts can help you select the right equipment to balance impact and attrition forces for maximum efficiency and consistency.

Contact our grinding specialists today to discuss how KINTEK's lab equipment can enhance your research and development outcomes!

Visual Guide

Related Products

- Stainless Steel Laboratory Ball Mill for Dry Powder and Liquid with Ceramic Polyurethane Lining

- Laboratory Ball Mill Jar Mill with Metal Alloy Grinding Jar and Balls

- Laboratory Single Horizontal Jar Mill

- Laboratory Four-Body Horizontal Jar Mill

- Laboratory Planetary Ball Mill Rotating Ball Milling Machine

People Also Ask

- What is the product size of a ball mill? Achieve Micron-Level Precision for Your Materials

- What role does a planetary ball mill play in eggshell fertilizer production? Unlock Superior Chemical Reactivity

- What is the function of ball milling equipment in NZSSP electrolyte preparation? Optimize NASICON Solid-State Synthesis

- How does a high-energy planetary ball mill facilitate the synthesis of sulfide glassy electrolytes? Achieve Amorphization

- Why use ball milling for NMC cathode materials? Achieve Precision Particle Sizing for Composite Cathodes