In materials science, cryo-milling is an advanced processing technique used for particle size reduction. The process involves placing a material into a high-energy ball mill that is submerged in a cryogenic liquid, typically liquid nitrogen. This extreme cold makes the material brittle, allowing the milling media to efficiently fracture it into a very fine, often nanocrystalline, powder.

The core purpose of cryo-milling is not simply to make particles smaller. It is a strategic method for processing materials that are otherwise difficult to mill—such as soft polymers or ductile metals—and for creating unique nanostructures while preventing heat-induced degradation.

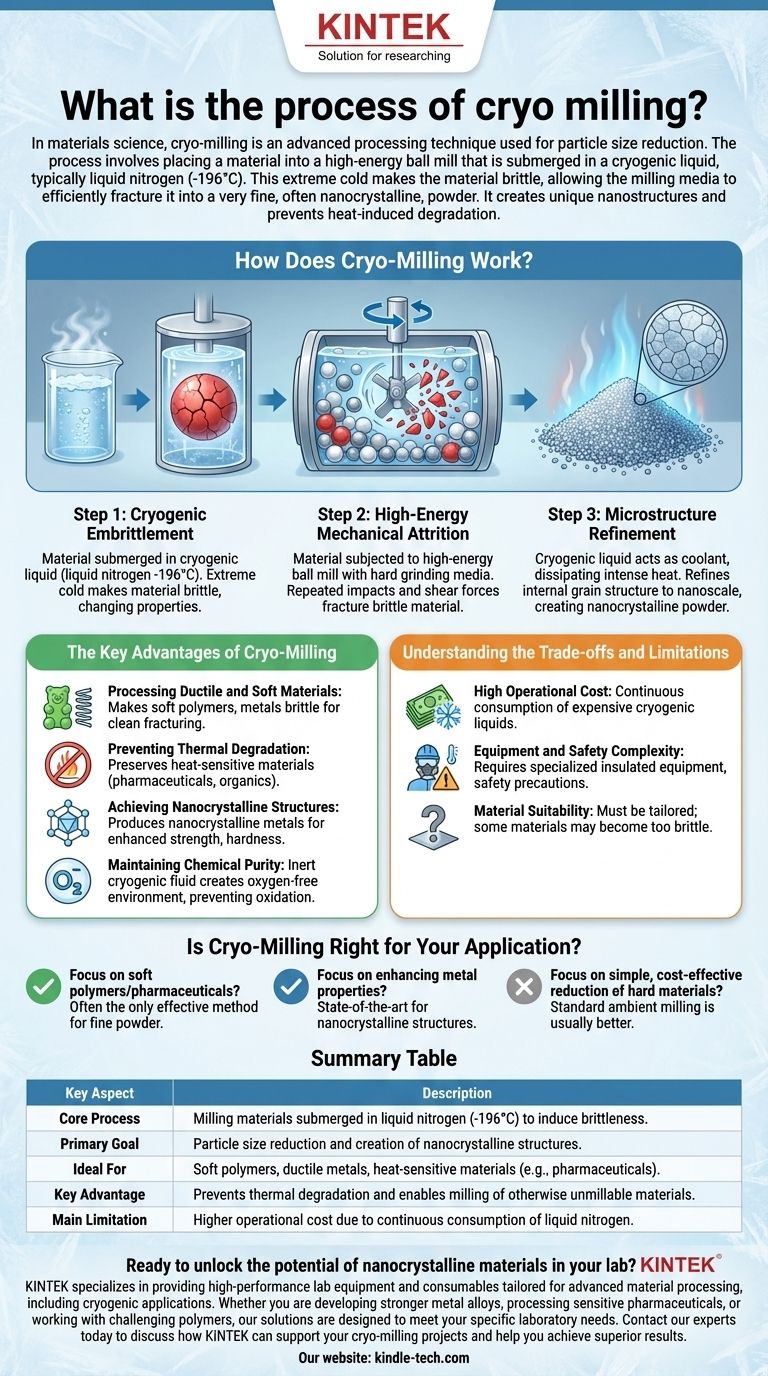

How Does Cryo-Milling Work?

The process combines two fundamental principles: cryogenic embrittlement and high-energy mechanical attrition. Each step is critical to the final outcome.

Step 1: Cryogenic Embrittlement

The material to be milled is first submerged in a cryogenic liquid, most commonly liquid nitrogen at -196°C (-321°F).

This extreme cold dramatically changes the material's properties, causing it to become very hard and brittle. This is the key enabler of the process.

Step 2: High-Energy Mechanical Attrition

Once embrittled, the material is subjected to a high-energy ball mill. This mill contains hard grinding media, such as steel or ceramic balls.

The mill's agitator causes constant, high-velocity collisions between the grinding media and the material particles. These repeated impacts and shear forces, known as attrition, effectively fracture the now-brittle material into smaller pieces.

Step 3: Microstructure Refinement

The cryogenic liquid serves a dual purpose: it not only causes embrittlement but also acts as a highly efficient coolant. It instantly dissipates the intense heat generated during milling.

This combination of severe plastic deformation at cryogenic temperatures can refine the material's internal grain structure down to the nanoscale, creating a nanocrystalline powder with enhanced properties.

The Key Advantages of Cryo-Milling

Engineers and scientists choose this method to solve specific challenges that conventional milling cannot address.

Processing Ductile and Soft Materials

Standard milling is ineffective for soft, elastic, or "gummy" materials like polymers and certain metals. At room temperature, these materials deform rather than fracture.

Cryo-milling makes them brittle, allowing them to be cleanly shattered into a fine powder.

Preventing Thermal Degradation

High-energy milling generates significant heat, which can damage or destroy heat-sensitive materials like pharmaceuticals, plastics, and organic compounds.

The cryogenic environment provides a constant, ultra-low temperature, preserving the material's chemical and structural integrity.

Achieving Nanocrystalline Structures

For metallurgists, cryo-milling is a primary method for producing nanocrystalline metals and alloys.

Reducing the grain size to the nanoscale can dramatically increase a material's strength, hardness, and wear resistance, opening up new possibilities for high-performance components.

Maintaining Chemical Purity

Milling in open air can cause oxidation, especially with reactive metal powders.

Using an inert cryogenic fluid like liquid nitrogen creates an oxygen-free environment, preventing contamination and preserving the material's purity.

Understanding the Trade-offs and Limitations

While powerful, cryo-milling is a specialized process with significant trade-offs that must be considered.

High Operational Cost

Cryogenic liquids are expensive consumables. The continuous need for liquid nitrogen or argon makes the process significantly more costly than ambient temperature milling.

Equipment and Safety Complexity

The process requires specialized, insulated milling equipment and careful handling of cryogenic fluids, which pose safety risks such as cold burns and asphyxiation in enclosed spaces.

Material Suitability

Not all materials are good candidates. While it excels for soft materials, some materials may become too brittle, leading to uncontrolled fracturing or undesirable properties. The process must be tailored to the specific material.

Is Cryo-Milling Right for Your Application?

Your choice depends entirely on your material and your ultimate goal.

- If your primary focus is processing soft polymers, elastomers, or heat-sensitive pharmaceuticals: Cryo-milling is often the only effective method to achieve a fine powder without degrading the material.

- If your primary focus is enhancing the mechanical properties of metals: Cryo-milling is a state-of-the-art tool for creating nanocrystalline structures that dramatically improve strength and hardness.

- If your primary focus is simple, cost-effective size reduction for hard, non-sensitive materials: Standard ambient temperature ball milling is almost always the more practical and economical choice.

By understanding its principles, you can leverage cryo-milling not just for size reduction, but as a strategic tool for advanced material design.

Summary Table:

| Key Aspect | Description |

|---|---|

| Core Process | Milling materials submerged in liquid nitrogen (-196°C) to induce brittleness. |

| Primary Goal | Particle size reduction and creation of nanocrystalline structures. |

| Ideal For | Soft polymers, ductile metals, heat-sensitive materials (e.g., pharmaceuticals). |

| Key Advantage | Prevents thermal degradation and enables milling of otherwise unmillable materials. |

| Main Limitation | Higher operational cost due to continuous consumption of liquid nitrogen. |

Ready to unlock the potential of nanocrystalline materials in your lab?

Cryo-milling is a sophisticated process that requires precision equipment and expertise. KINTEK specializes in providing high-performance lab equipment and consumables tailored for advanced material processing, including cryogenic applications.

Whether you are developing stronger metal alloys, processing sensitive pharmaceuticals, or working with challenging polymers, our solutions are designed to meet your specific laboratory needs.

Contact our experts today to discuss how KINTEK can support your cryo-milling projects and help you achieve superior results.

Visual Guide

Related Products

- Laboratory Planetary Ball Mill Rotating Ball Milling Machine

- Laboratory Horizontal Planetary Ball Mill Milling Machine

- 10L Chilling Circulator Cooling Water Bath Low Temperature Constant Temperature Reaction Bath

- High Energy Vibratory Laboratory Ball Mill Double Tank Type

- High-Energy Omnidirectional Planetary Ball Mill Milling Machine for Laboratory

People Also Ask

- What is the difference between a ball mill and a planetary mill? Choose the Right Grinding Tool for Your Lab

- What is the principle of planetary ball mill? Achieve Rapid, High-Energy Grinding for Your Materials

- How does a planetary mill work? Harnessing High-Energy Impact for Nano-Grinding

- What is the difference between a ball mill and a planetary ball mill? Unlock the Right Grinding Technology for Your Lab

- What are the parameters of a planetary ball mill? Master Speed, Time, and Media for Perfect Grinding