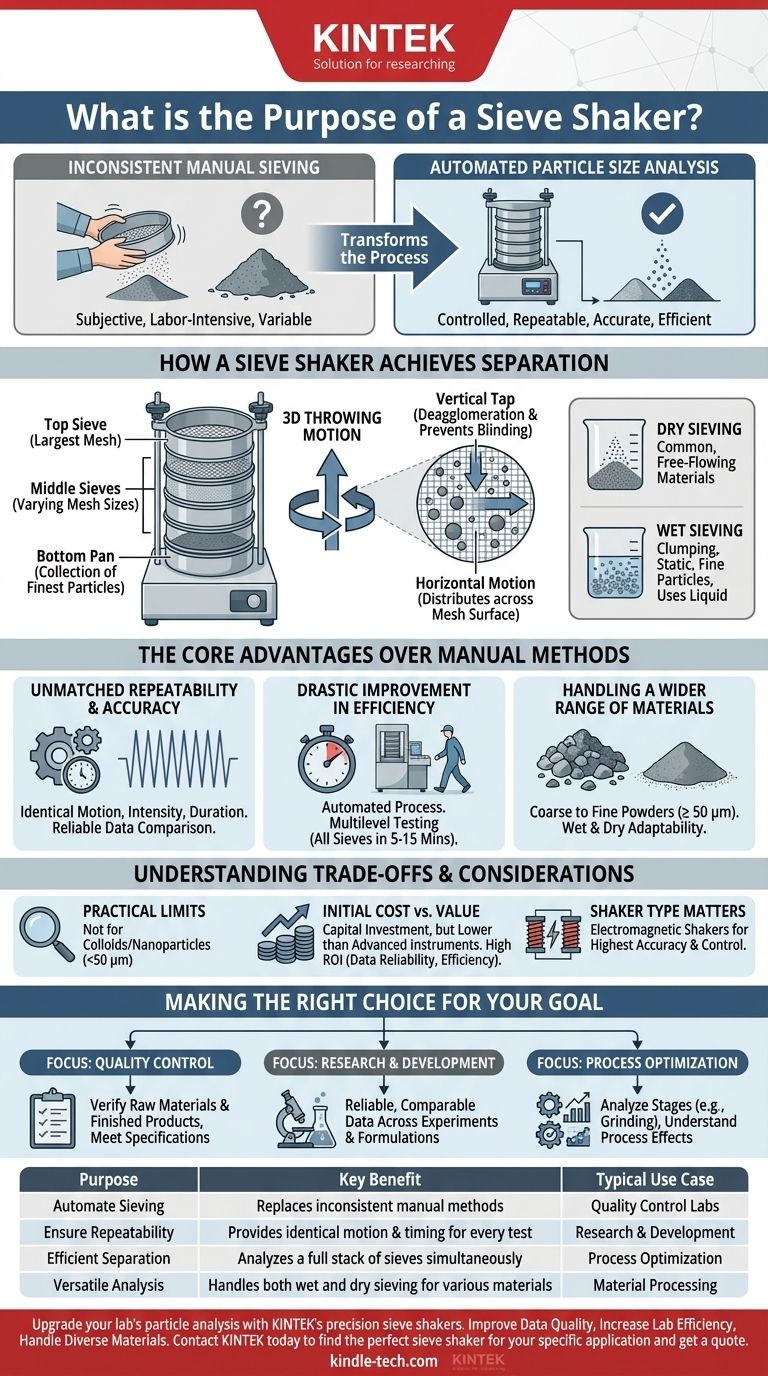

The primary purpose of a sieve shaker is to automate the process of particle size analysis. It uses mechanical agitation to consistently and efficiently separate a granular sample through a stack of test sieves, each with a different mesh size, allowing you to determine the particle size distribution of the material.

While manual hand sieving can provide a rough estimate, it is fundamentally inconsistent and labor-intensive. A sieve shaker replaces this subjective process with a controlled, repeatable, and accurate method, making it an indispensable tool for quality control, research, and material processing.

How a Sieve Shaker Achieves Separation

A sieve shaker’s function seems simple, but its design is engineered to ensure every particle is properly tested against the sieve mesh. This reliability is built on a few core principles.

The Sieve Stack Principle

A sieve shaker operates on a stack of test sieves. This stack is arranged vertically, with the sieve having the largest mesh openings on top and the one with the smallest openings at the bottom, followed by a solid collection pan.

As the shaker agitates the stack, larger particles are retained on the upper sieves while smaller particles pass through to the sieves below. This process continues until each particle is captured on a sieve with openings too small for it to pass through.

The Critical Role of Motion

Effective separation requires more than just simple back-and-forth shaking. High-quality sieve shakers impart a 3D throwing motion, combining a vertical tapping movement with a horizontal circular or orbital motion.

This complex movement is crucial. The vertical tap lifts the material, deagglomerates particles, and prevents the sieve mesh from becoming clogged (an issue known as blinding). The horizontal motion distributes the material across the entire surface of the sieve, ensuring every particle has a chance to pass through an opening.

Wet vs. Dry Sieving

Sieve shakers can be used for both wet and dry analysis. Dry sieving is the most common method, suitable for free-flowing materials.

Wet sieving is used when a material is prone to clumping, static electricity, or contains very fine particles that can agglomerate. A liquid (usually water) is used to disperse the particles and carry them through the sieves, ensuring an accurate separation.

The Core Advantages Over Manual Methods

Moving from manual sieving to a mechanical shaker is a significant upgrade in data quality and operational efficiency. The benefits extend far beyond simply saving labor.

Unmatched Repeatability and Accuracy

The single greatest advantage is repeatability. A sieve shaker delivers the exact same motion, at the same intensity, for the exact same duration, every single time.

This removes the variability introduced by different operators or even the same operator on different days. The result is accurate and reproducible particle sizing data that can be reliably compared over time, a requirement for any serious quality control program or scientific research.

Drastic Improvement in Efficiency

A sieve shaker automates what is otherwise a tedious and time-consuming manual task. It allows a technician to load the sample, set the timer, and walk away.

Furthermore, it enables multilevel testing by agitating an entire stack of sieves at once, providing a complete particle size distribution in a single run that might take 5-15 minutes.

Handling a Wider Range of Materials

Modern shakers are versatile instruments. They are capable of analyzing a broad spectrum of materials, from coarse aggregates down to fine powders as small as 50 micrometers (µm). Their ability to perform both wet and dry sieving makes them adaptable to nearly any type of granular sample.

Understanding the Trade-offs and Considerations

While highly effective, a sieve shaker is a specific tool with its own set of practical considerations. Understanding its limitations is key to using it correctly.

It Is Not a Universal Solution

Sieve analysis has a practical lower limit. For particles in the very fine or sub-micron range, other methods like laser diffraction or dynamic light scattering become more appropriate. A sieve shaker is the standard for granular and powdered materials but not for colloids or nanoparticles.

Initial Cost vs. Long-Term Value

Compared to a set of pans and manual labor, a sieve shaker represents a capital investment. However, its cost is often significantly lower than more advanced particle analysis instruments. The return on investment is realized through improved data reliability, reduced labor costs, and enhanced product quality.

The Importance of Shaker Type

Not all shakers are created equal. Basic mechanical shakers are common, but electromagnetic sieve shakers are often recommended for applications demanding the highest levels of accuracy. These units use electromagnetic pulses to create a precise and controllable 3D motion, ensuring superior repeatability.

Making the Right Choice for Your Goal

Ultimately, a sieve shaker transforms particle analysis from a subjective task into a quantitative measurement. How you apply it depends on your specific objective.

- If your primary focus is routine quality control: A sieve shaker provides the essential repeatability to quickly verify that incoming raw materials and outgoing finished products meet specifications.

- If your primary focus is research and development: The accuracy and controlled parameters of a sieve shaker ensure your particle size data is reliable and comparable across different experiments and formulations.

- If your primary focus is process optimization: Use a sieve shaker to analyze materials at different stages, helping you understand how processes like grinding or granulation are affecting your particle size distribution.

By automating and standardizing the separation process, a sieve shaker provides the reliable data needed to make informed decisions about your materials.

Summary Table:

| Purpose | Key Benefit | Typical Use Case |

|---|---|---|

| Automate Sieving | Replaces inconsistent manual methods | Quality Control Labs |

| Ensure Repeatability | Provides identical motion & timing for every test | Research & Development |

| Efficient Separation | Analyzes a full stack of sieves simultaneously | Process Optimization |

| Versatile Analysis | Handles both wet and dry sieving for various materials | Material Processing |

Upgrade your lab's particle analysis with KINTEK's precision sieve shakers.

Are inconsistent manual sieving methods impacting your quality control data? KINTEK specializes in lab equipment that delivers the accuracy and repeatability your laboratory demands. Our range of sieve shakers is engineered to provide the controlled, 3D motion necessary for reliable particle size distribution analysis, saving you time and ensuring your results are trustworthy.

Let us help you achieve superior results:

- Improve Data Quality: Eliminate operator variability with automated, repeatable shaking.

- Increase Lab Efficiency: Free up your technicians from tedious manual sieving.

- Handle Diverse Materials: Perform both wet and dry sieving for a wide range of samples.

Contact KINTEK today to find the perfect sieve shaker for your specific application and get a quote.

Visual Guide

Related Products

- Laboratory Test Sieves and Sieving Machines

- Three-dimensional electromagnetic sieving instrument

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Filter Testing Machine FPV for Dispersion Properties of Polymers and Pigments

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

People Also Ask

- What is the primary function of a mechanical sieve shaker for biomass analysis? Optimize Particle Size Distribution

- What are the factors affecting sieving performance and efficiency? Optimize Your Particle Separation Process

- What are the specifications for test sieves? A Guide to ASTM & ISO Standards for Accurate Particle Analysis

- What is the primary purpose of using standard sieves? Master Particle Uniformity for High-Quality Catalyst Preparation

- Why is a precision vibrating sieve shaker essential for metal leaching research? Optimize Your Particle Size Analysis