At its core, screw extrusion is a continuous manufacturing process that uses a rotating screw inside a heated barrel to transform raw plastic pellets into a continuous, shaped product. The screw melts, mixes, and pressurizes the material, forcing it through a specially designed opening called a die to create a profile with a constant cross-section, such as a pipe, tube, or window frame.

Screw extrusion is not just about pushing material; it's a precisely controlled thermal and mechanical process that melts, conveys, and shapes raw polymers into a continuous profile. The screw's design and rotational speed are the primary controls for both quality and production rate.

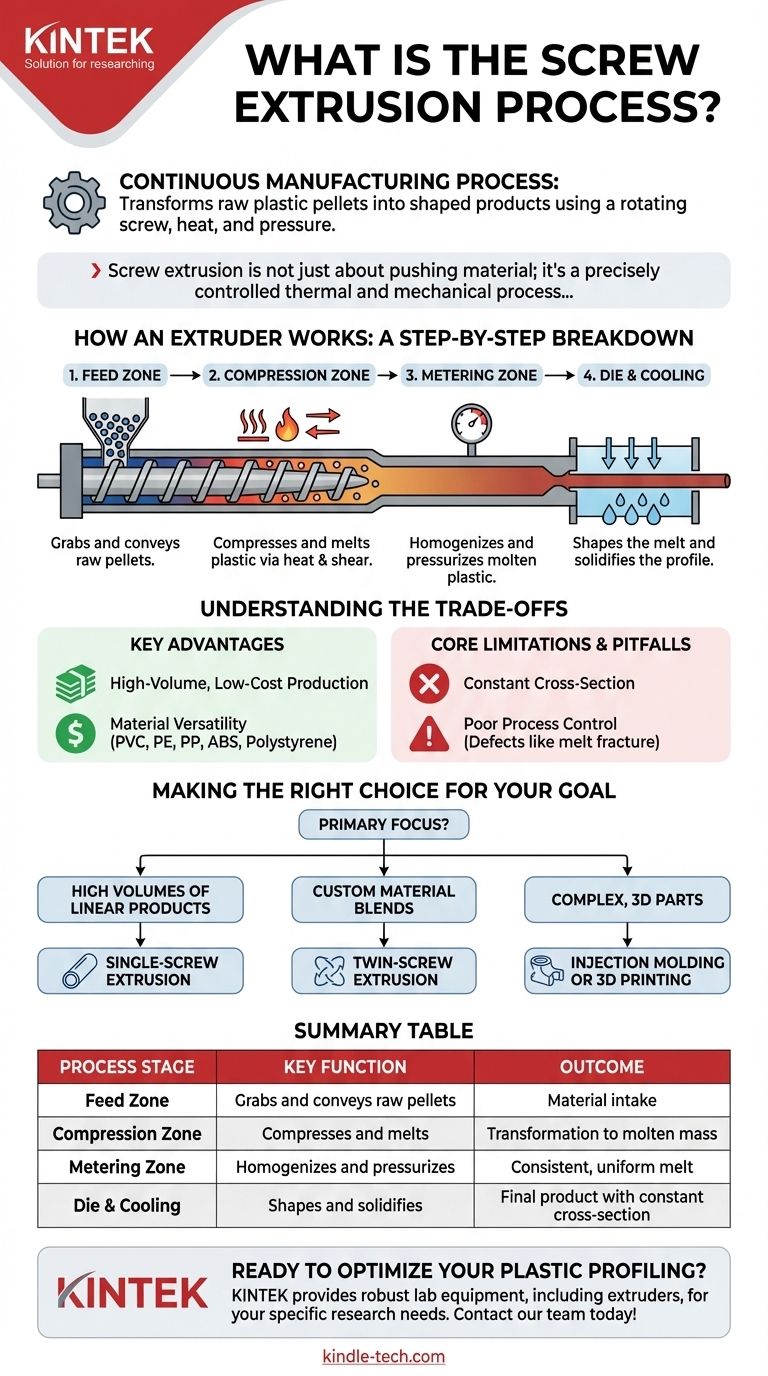

How an Extruder Works: A Step-by-Step Breakdown

To truly understand the process, you must see the extruder as a system with distinct functional zones, each with a specific purpose. The journey from raw pellet to finished profile happens in stages along the length of the screw and barrel.

The Feed Zone

This is the entry point. Raw plastic material, typically in pellet or powder form, is gravity-fed from a hopper into the barrel. The screw channels in this section are deep, designed simply to grab the material and convey it forward into the machine.

The Compression (or Transition) Zone

This is where the transformation begins. The depth of the screw channel gradually decreases, compressing the plastic pellets. This compression, combined with heat from external barrel heaters and the immense shear friction from the rotating screw, causes the plastic to melt and compact.

The Metering Zone

In the final section of the screw, the channel depth is shallow and constant. The primary purpose here is to homogenize the molten plastic, ensuring a consistent temperature and eliminating any remaining solid particles. This zone builds the final, stable pressure needed to push the melt through the die at a uniform rate.

The Die and Cooling

The fully molten, pressurized plastic exits the screw and is forced through the die. The die is a precisely machined tool that imparts the final shape to the material. After exiting the die, the continuous profile is immediately cooled, typically in a water bath or by air jets, to solidify it and lock in its shape.

Understanding the Trade-offs

Like any manufacturing process, screw extrusion has distinct capabilities and limitations that make it ideal for some applications and unsuitable for others.

Key Advantage: High-Volume, Low-Cost Production

For creating products with a constant cross-section, extrusion is one of the most efficient and cost-effective methods available. Its continuous nature makes it ideal for producing thousands of feet of pipe, tubing, or weather stripping with minimal labor.

Key Advantage: Material Versatility

The process works with a massive range of thermoplastic materials, including PVC, Polyethylene (PE), Polypropylene (PP), ABS, and Polystyrene. This allows for a wide array of product characteristics, from rigid pipes to flexible seals.

Core Limitation: Constant Cross-Section

The fundamental limitation of extrusion is that it can only produce parts with a uniform profile along their length. It cannot create discrete, complex parts with varying geometry, which is the domain of processes like injection molding.

Common Pitfall: Poor Process Control

The quality of an extruded product is highly sensitive to process variables. Improper temperature profiles, inconsistent screw speed, or variations in raw material can lead to defects such as rough surfaces ("melt fracture"), dimensional inaccuracies, or internal voids.

Making the Right Choice for Your Goal

Selecting the right manufacturing process depends entirely on your end goal. Use these guidelines to determine if screw extrusion fits your needs.

- If your primary focus is producing high volumes of linear products: For items like pipes, decking, wire insulation, or window frames, single-screw extrusion is the most efficient and economical choice.

- If your primary focus is creating custom material blends: For applications requiring the mixing of additives, fillers, or colorants into a base polymer, a more complex twin-screw extruder is the necessary tool.

- If your primary focus is creating complex, three-dimensional parts: Extrusion is the wrong process; you should investigate discrete manufacturing methods like injection molding or 3D printing.

Understanding the fundamentals of the extrusion process transforms it from a simple machine into a powerful tool for material transformation.

Summary Table:

| Process Stage | Key Function | Outcome |

|---|---|---|

| Feed Zone | Grabs and conveys raw pellets into the barrel. | Material intake and initial forward movement. |

| Compression Zone | Compresses and melts plastic via heat and shear. | Transformation from solid pellets to a molten mass. |

| Metering Zone | Homogenizes and pressurizes the molten plastic. | Consistent, uniform melt ready for shaping. |

| Die & Cooling | Shapes the melt and solidifies the profile. | Final product with a constant cross-section. |

Ready to optimize your plastic profiling or material compounding? The right equipment is critical for achieving high-quality, consistent results. At KINTEK, we specialize in providing robust and reliable lab equipment, including extruders, to meet your specific research and development needs. Whether you're working with standard thermoplastics or developing new custom blends, our experts can help you select the perfect solution. Contact our team today to discuss how KINTEK can support your laboratory's extrusion and material processing goals!

Visual Guide

Related Products

- Twin Screw Extruder Plastic Granulation Machine

- Filter Testing Machine FPV for Dispersion Properties of Polymers and Pigments

- Laboratory Test Sieves and Sieving Machines

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Anti-Cracking Press Mold for Lab Use

People Also Ask

- What are the disadvantages of the extrusion process? High Costs and Geometric Limits Explained

- What is the difference between extrusion and co-extrusion? Engineer Multi-Material Parts

- What is the meaning of blowing film? A Guide to Biaxial Orientation and Stronger Plastic Films

- What are the advantages of coextrusion? Achieve Multi-Material Efficiency and Superior Performance

- What are the advantages of waste plastic pyrolysis? Transform Waste into Valuable Fuel and Chemicals