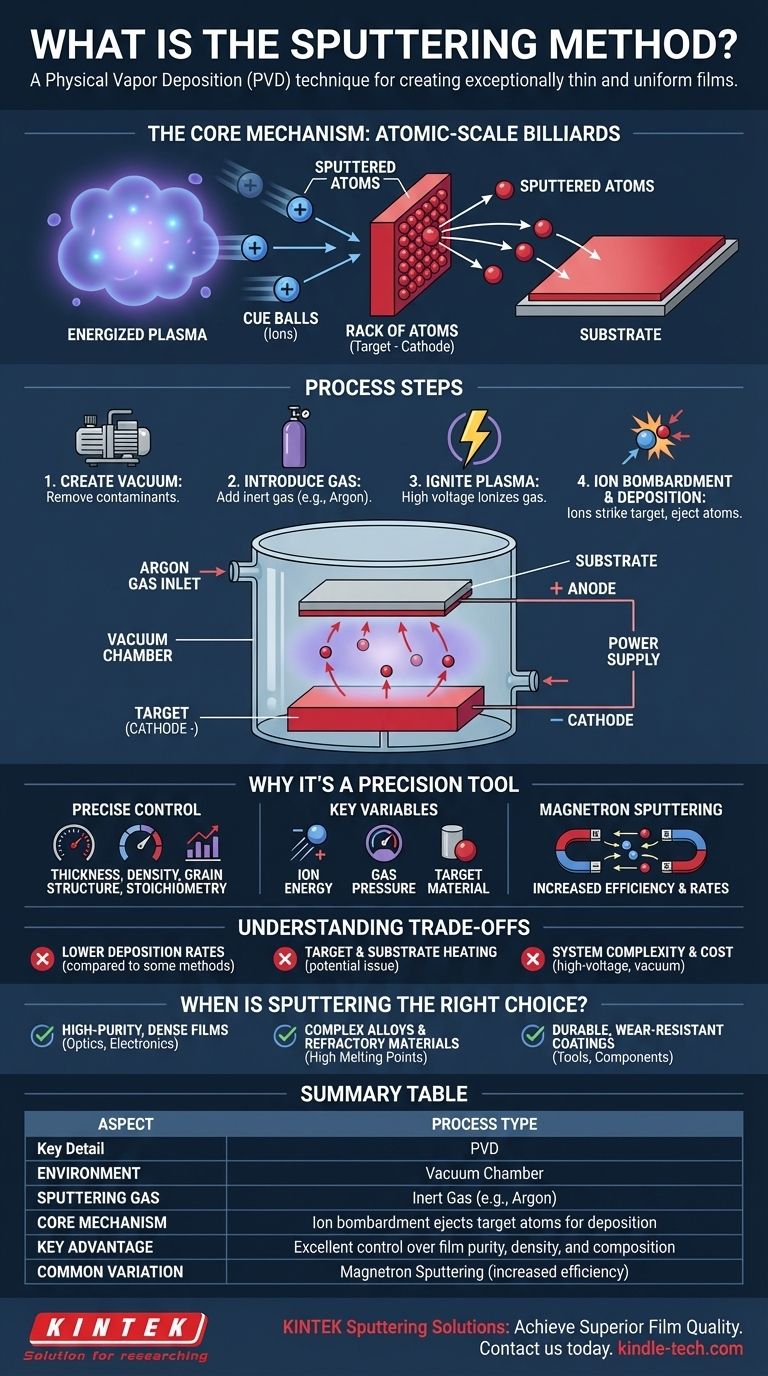

In essence, sputtering is a physical vapor deposition (PVD) method used to deposit exceptionally thin and uniform layers of material onto a surface. The process takes place in a vacuum and uses an energized gas, or plasma, to physically knock atoms from a source material (the "target") and deposit them onto a substrate, forming a high-performance film atom by atom.

Sputtering is fundamentally a process of atomic-scale billiards. By energizing an inert gas into a plasma, we create "cue balls" (ions) that strike a "rack" of atoms (the target), knocking them loose to land precisely on a nearby surface (the substrate).

The Core Mechanism: From Plasma to Thin Film

To understand sputtering, it's best to visualize it as a sequence of controlled events happening inside a vacuum chamber. Each step is critical for the final quality of the film.

Creating the Vacuum Environment

The entire process occurs in a vacuum chamber. This is crucial to remove air and other particles that could contaminate the film or interfere with the movement of sputtered atoms.

Introducing the Sputtering Gas

A small, controlled amount of a high-purity inert gas, most commonly Argon, is introduced into the chamber. This gas is the "ammunition" for the process; its atoms will be energized to bombard the target.

Igniting the Plasma

A high voltage is applied within the chamber, with the target material acting as the cathode (negative charge). This powerful electric field strips electrons from the Argon atoms, creating a glowing, ionized gas known as a plasma—a mix of positively charged Argon ions and free electrons.

The Ion Bombardment

The positively charged Argon ions are now strongly accelerated by the electric field, causing them to collide with the negatively charged target at high velocity and energy.

Atomic Ejection and Deposition

This bombardment is a pure momentum transfer event. When the energetic ions strike the target, they initiate a collision cascade within the material's atomic structure. When this cascade reaches the surface, it ejects individual atoms from the target.

These ejected atoms travel through the vacuum chamber, typically in a line of sight, until they strike the substrate (such as a silicon wafer, glass pane, or plastic part). Upon arrival, they stick and condense, gradually building up a thin, uniform film.

Why Sputtering is a Precision Tool

Sputtering is valued not just for its ability to coat a surface, but for the incredible degree of control it offers. The properties of the final film can be precisely engineered.

Control Over Film Properties

Because sputtering builds a film atom by atom, it allows for exquisite control over film thickness, density, grain structure, and stoichiometry (the precise ratio of elements in a compound). This makes it indispensable for creating materials with specific electrical, optical, or protective properties.

Key Control Variables

The process is highly tunable. Experts adjust several variables to achieve the desired outcome, including:

- Ion Energy: Higher energy results in more sputtered atoms per ion.

- Gas Pressure: Affects the plasma density and the path of the sputtered atoms.

- Target Material: The binding energy and atomic mass of the target material determine how easily atoms are ejected.

A Common Variation: Magnetron Sputtering

To make the process more efficient, most modern systems use magnetron sputtering. Powerful magnets are placed behind the target to trap the free electrons from the plasma. These trapped electrons are forced to spiral near the target surface, dramatically increasing the number of collisions with Argon atoms and creating a much denser, more effective plasma. This significantly increases deposition rates.

Understanding the Trade-offs

While powerful, sputtering is not the universal solution for all coating needs. Understanding its limitations is key to making an informed decision.

Deposition Rates

Compared to some other methods like thermal evaporation, sputtering can have a lower deposition rate. While magnetron sputtering improves speed, it can still be a slower process, which is a factor in high-volume manufacturing.

Target and Substrate Heating

The constant ion bombardment generates significant heat in the target. Furthermore, the energy from the plasma and depositing atoms can heat the substrate, which may be a problem for heat-sensitive materials like certain plastics.

System Complexity and Cost

Sputtering systems require a vacuum chamber, high-voltage power supplies, gas handling, and often advanced cooling and magnetic arrays. This makes the equipment more complex and expensive than simpler deposition techniques.

When is Sputtering the Right Choice?

Choosing a deposition method depends entirely on the technical requirements of your final product.

- If your primary focus is high-purity, dense films with precise thickness: Sputtering offers exceptional control over film morphology and composition, making it ideal for optics, electronics, and medical devices.

- If your primary focus is coating complex alloys or refractory materials: Sputtering excels at depositing materials with very high melting points (like tungsten or titanium) that are difficult or impossible to evaporate thermally.

- If your primary focus is creating durable, wear-resistant coatings: The high energy of sputtered atoms leads to excellent adhesion and dense film structures, perfect for hard coatings on tools and components.

Ultimately, sputtering serves as a cornerstone of modern materials science, enabling the fabrication of the advanced thin films that power our technology.

Summary Table:

| Aspect | Key Detail |

|---|---|

| Process Type | Physical Vapor Deposition (PVD) |

| Environment | Vacuum Chamber |

| Sputtering Gas | Inert Gas (e.g., Argon) |

| Core Mechanism | Ion bombardment ejects target atoms for deposition |

| Key Advantage | Excellent control over film purity, density, and composition |

| Common Variation | Magnetron Sputtering (increased efficiency) |

Ready to integrate precision sputtering into your lab's capabilities?

KINTEK specializes in high-quality lab equipment and consumables for all your thin film deposition needs. Our sputtering solutions are designed to help you achieve superior film quality, precise control, and reliable results for applications in electronics, optics, and durable coatings.

Contact us today to discuss how our expertise can advance your materials science projects!

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Electron Beam Evaporation Coating Oxygen-Free Copper Crucible and Evaporation Boat

- Aluminized Ceramic Evaporation Boat for Thin Film Deposition

People Also Ask

- What is the difference between PECVD and APCVD? Choose the Right CVD Method for Your Application

- What is the process of PECVD in semiconductor? Enabling Low-Temperature Thin Film Deposition

- Can plasma enhanced CVD deposit metals? Why PECVD is rarely used for metal deposition

- What are the process capabilities of ICPCVD systems? Achieve Low-Damage Film Deposition at Ultra-Low Temperatures

- What is the difference between plasma CVD and thermal CVD? Choose the Right Method for Your Substrate