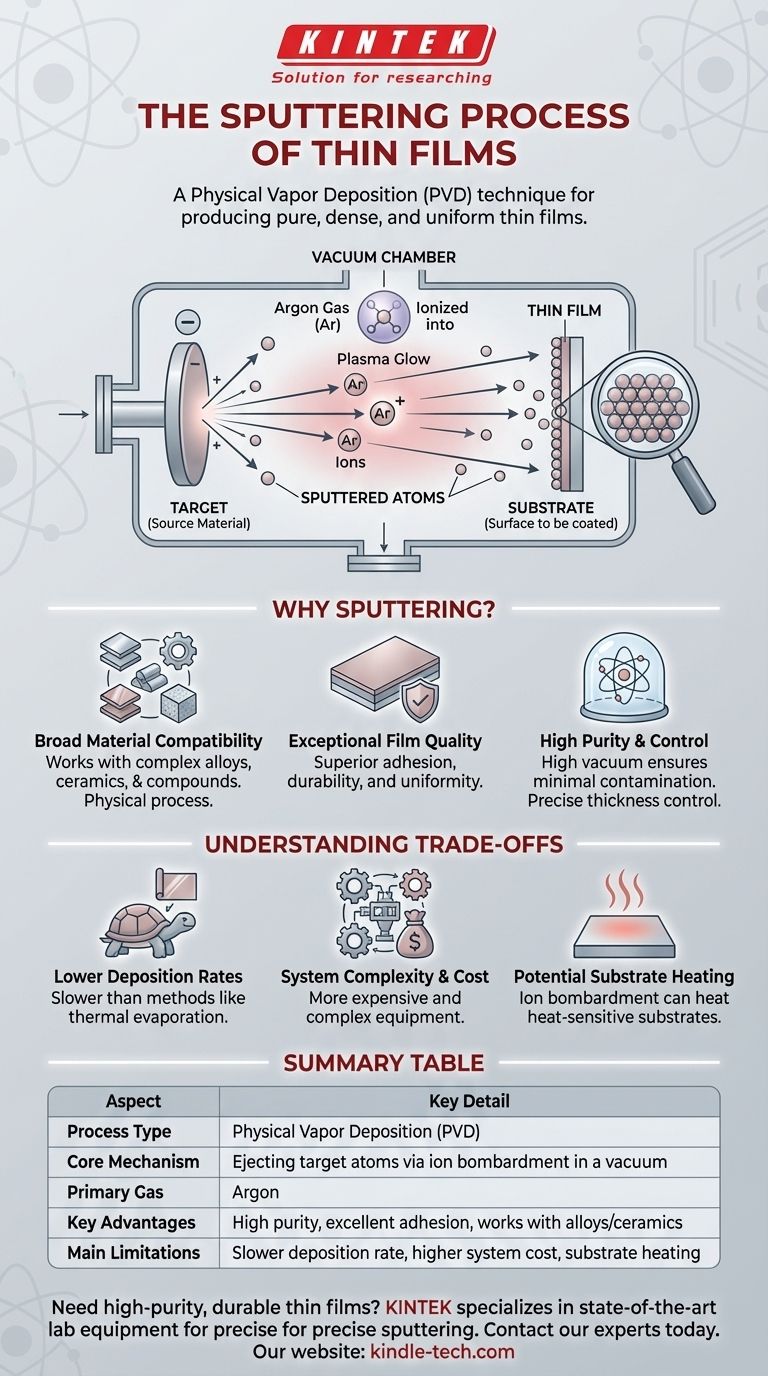

In the simplest terms, sputtering is a physical process used to deposit an exceptionally thin layer of material onto a surface. It works by ejecting atoms from a source material (called a "target") by bombarding it with energized ions inside a vacuum chamber. These ejected atoms then travel and coat a secondary surface (the "substrate"), forming the thin film.

Sputtering is a highly controlled and versatile Physical Vapor Deposition (PVD) technique. Its core value lies in its ability to produce very pure, dense, and uniform thin films from a vast range of materials, making it a cornerstone of modern manufacturing.

The Core Mechanism: From Ion to Film

To understand sputtering, it helps to visualize it as a microscopic game of atomic billiards. The entire process takes place inside a sealed vacuum chamber to prevent contamination.

Step 1: Creating the Environment

The process begins by creating a high vacuum in a chamber. A small amount of an inert gas, typically Argon, is then introduced. This gas provides the "projectiles" needed for the next step.

Step 2: Energizing the Ions

A powerful electric field is applied within the chamber, which strips electrons from the Argon atoms, turning them into positively charged ions. This creates a plasma, often visible as a characteristic glow.

Step 3: Bombarding the Target

The source material to be deposited, known as the target, is given a negative charge. This powerful negative potential aggressively attracts the positively charged Argon ions, causing them to accelerate and slam into the target with significant force.

Step 4: Deposition on the Substrate

This high-energy collision physically knocks atoms loose from the target material, "sputtering" them away. These ejected atoms travel in a straight line through the vacuum until they strike the object being coated—the substrate—where they condense and build up, layer by layer, to form a thin film.

Why Sputtering is a Foundational Technique

While several methods exist for creating thin films, sputtering is exceptionally common due to its unique advantages in control and material flexibility.

Broad Material Compatibility

Unlike some methods that rely on melting and evaporating materials, sputtering is a physical process. This means it can be used to deposit almost any material, including complex alloys, ceramics, and compounds, without altering their chemical composition.

Exceptional Film Quality

The kinetic energy of the sputtered atoms helps them form a very dense and tightly packed film on the substrate. This results in coatings with superior adhesion, durability, and uniformity compared to other techniques.

High Purity and Control

Because the process occurs in a high vacuum, there are very few stray molecules to contaminate the film. This allows for the creation of extremely pure coatings. Furthermore, the rate of deposition can be precisely controlled, allowing for films of a specific, repeatable thickness down to the atomic level.

Understanding the Trade-offs

No single process is perfect for every application. Building trust requires acknowledging the limitations of a technique.

Lower Deposition Rates

Sputtering is generally a slower process compared to other methods like thermal evaporation. When the goal is to deposit a very thick coating quickly, sputtering may not be the most efficient choice.

System Complexity and Cost

Sputtering systems, with their high-vacuum pumps, power supplies, and control electronics, are more complex and expensive than simpler deposition methods.

Potential Substrate Heating

The constant bombardment of atoms and ions can transfer a significant amount of energy to the substrate, causing it to heat up. This can be a challenge when coating heat-sensitive materials like certain plastics or organic compounds.

Making the Right Choice for Your Application

Selecting a deposition method depends entirely on the desired outcome for the final product.

- If your primary focus is high-purity, dense coatings with strong adhesion: Sputtering is almost always the superior choice, especially for complex materials like alloys or optical coatings.

- If your primary focus is depositing a simple metal film as quickly and cheaply as possible: A technique like thermal evaporation might be a more practical alternative.

- If your primary focus is coating a complex, three-dimensional shape with a uniform layer: A non-line-of-sight method like Chemical Vapor Deposition (CVD) may be better suited for the task.

Ultimately, understanding the core principles of sputtering empowers you to select the right tool for creating high-performance materials.

Summary Table:

| Aspect | Key Detail |

|---|---|

| Process Type | Physical Vapor Deposition (PVD) |

| Core Mechanism | Ejecting target atoms via ion bombardment in a vacuum |

| Primary Gas Used | Argon |

| Key Advantages | High purity, excellent adhesion, works with alloys/ceramics |

| Main Limitations | Slower deposition rate, higher system cost, substrate heating |

Need a high-purity, durable thin film for your project? Sputtering is the ideal solution for demanding applications in semiconductor manufacturing, advanced optics, and R&D. KINTEK specializes in providing state-of-the-art lab equipment and consumables for precise sputtering processes. Our expertise ensures you achieve the uniform, contaminant-free coatings your work requires. Contact our experts today to discuss how we can support your laboratory's thin film deposition needs.

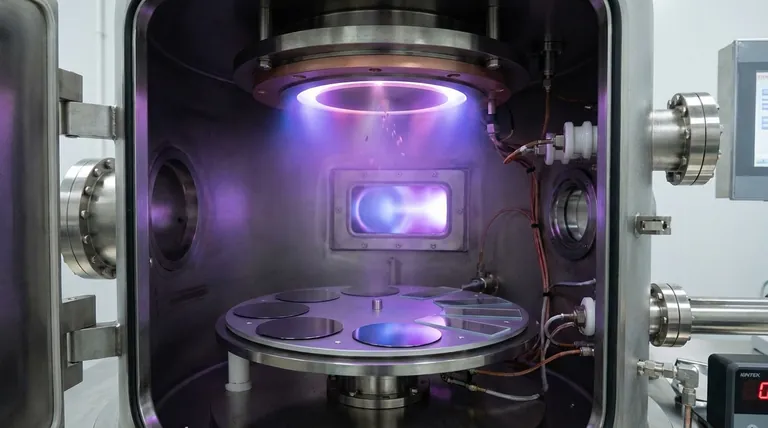

Visual Guide

Related Products

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Benchtop Laboratory Vacuum Freeze Dryer

People Also Ask

- How are reactants introduced into the reaction chamber during a CVD process? Mastering Precursor Delivery Systems

- How is something diamond coated? A Guide to CVD Growth vs. Plating Methods

- How does PACVD equipment improve DLC coatings? Unlock Low Friction and High Heat Resistance

- What is microwave plasma CVD? A Guide to High-Purity Diamond and Material Synthesis

- What is the role of the HF-CVD system in preparing BDD electrodes? Scalable Solutions for Boron-Doped Diamond Production