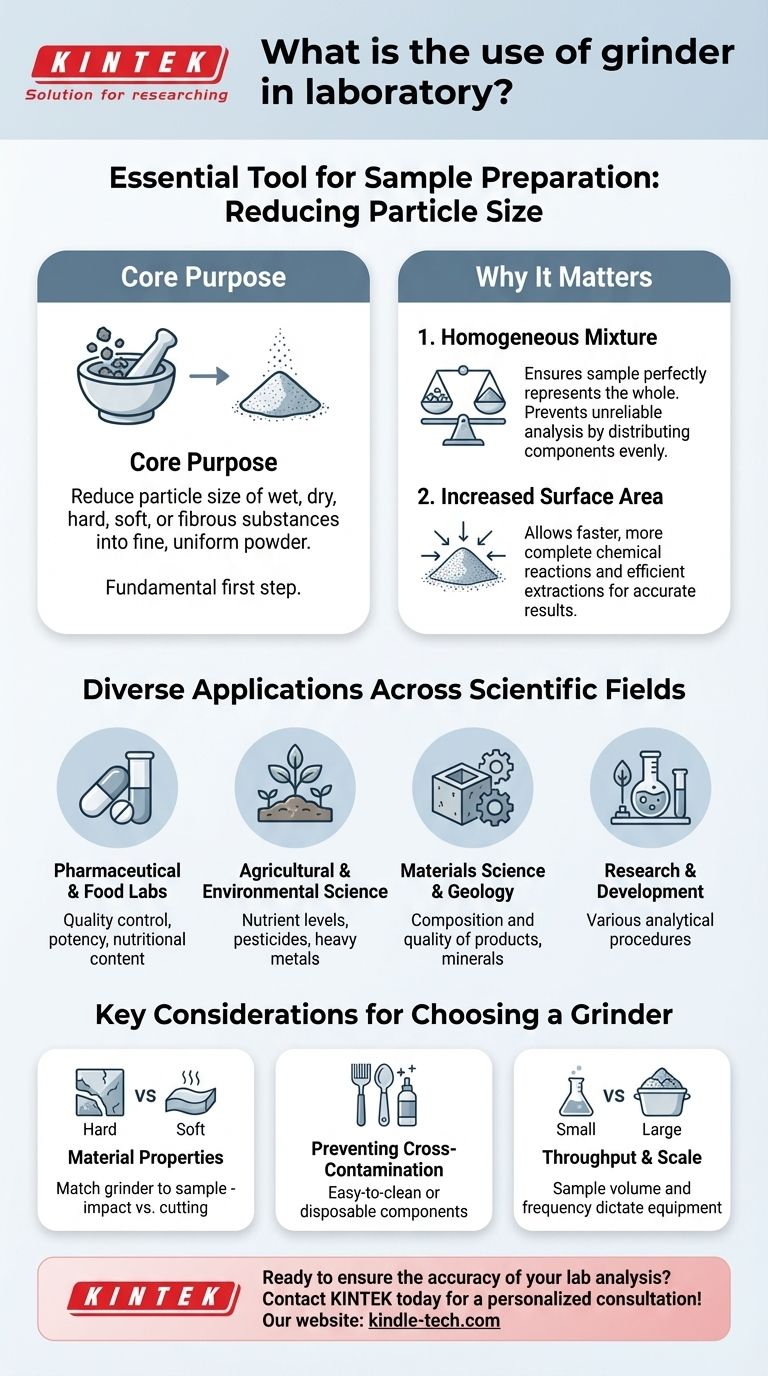

In short, a laboratory grinder is an essential tool used to reduce the particle size of a sample. Its core purpose is to grind or homogenize a wide variety of materials—including wet, dry, hard, soft, or fibrous substances—into a fine, uniform powder. This process is a fundamental first step for countless analytical procedures.

The true value of a laboratory grinder isn't just about making things smaller. It's about creating a perfectly uniform and representative sample, which is the non-negotiable foundation for achieving accurate, repeatable, and reliable scientific results.

The Core Function: Why Sample Preparation Matters

Nearly every analytical measurement in a lab is performed on a tiny fraction of a much larger original material. The grinder's job is to ensure that this tiny fraction perfectly represents the whole.

Creating a Homogeneous Mixture

Homogenization is the process of making something uniform throughout. A lab grinder achieves this by crushing and mixing a sample until its components are evenly distributed.

Without this step, your analysis would be unreliable. Imagine testing a chunk of rock with a visible vein of gold; the results would be wildly different depending on whether your subsample came from the gold vein or the surrounding rock. Grinding the entire chunk ensures the gold is evenly dispersed, making any subsample truly representative.

Increasing Surface Area for Analysis

Breaking a material down into a fine powder dramatically increases its total surface area. This is critical for any process that involves dissolving the sample or extracting a specific compound from it.

A larger surface area allows solvents and reagents to interact with the sample material more quickly and completely. This leads to faster reactions, more efficient extractions, and ultimately, more accurate measurements.

Diverse Applications Across Scientific Fields

The fundamental need for uniform samples means grinders are indispensable across a vast range of industries and research areas. The type of grinder may change, but the principle remains the same.

In Pharmaceutical and Food Labs

These labs rely on grinders for quality control. To verify the potency of a medication or the nutritional content of a food product, a sample must be homogenized before chemical analysis. This ensures that the measured amount of an active ingredient or nutrient is accurate.

In Agricultural and Environmental Science

When testing soil, seeds, or plant tissue, grinders are used to prepare samples for analysis of nutrient levels, pesticides, or heavy metal contamination. This ensures that the results reflect the overall condition of the sample, not just one isolated spot.

In Materials Science and Geology

Manufacturers of building materials use grinders to test the composition and quality of products like cement and ceramics. Geologists grind down rocks and minerals to prepare them for compositional analysis, which is crucial for identifying their properties and origin.

Understanding the Trade-offs and Considerations

Not all grinders are the same, and choosing the right one involves understanding key practical factors. The scale of the equipment can range from large floor-standing machines to delicate benchtop units.

Matching the Grinder to the Material

The physical properties of the sample dictate the grinding method. A brittle material might require an impact-based mill, while a fibrous, elastic material might need a cutting mill. Using the wrong type can be ineffective or even damage the equipment.

Preventing Cross-Contamination

A significant challenge in sample preparation is preventing cross-contamination between samples. After grinding one material, the equipment must be meticulously cleaned to ensure no residue is left behind to corrupt the next one. This is why many high-precision labs use grinders with easily cleanable or disposable components.

Throughput and Scale

The required sample volume and frequency of use are critical factors. A quality control lab testing hundreds of samples daily will need a robust "workhorse" grinder designed for repetitive use. In contrast, a research lab preparing a few unique samples may use more delicate, specialized equipment.

Making the Right Choice for Your Goal

The specific objective of your analysis should guide your approach to sample preparation.

- If your primary focus is highly sensitive chemical analysis: You need to produce a very fine, homogenous powder to maximize surface area and ensure complete extraction of the target compound.

- If your primary focus is quality control of a bulk product: You need a grinder capable of processing a large enough initial sample to be statistically representative of the entire batch.

- If your primary focus is preserving heat-sensitive molecules: You may need specialized cryogenic grinding methods that use liquid nitrogen to keep the sample frozen and prevent degradation.

Ultimately, proper grinding is the foundational step that ensures the integrity and validity of all subsequent laboratory work.

Summary Table:

| Purpose | Key Benefit | Common Applications |

|---|---|---|

| Homogenization | Creates a uniform, representative sample | Pharmaceutical QC, Food Testing |

| Particle Size Reduction | Increases surface area for efficient analysis | Soil Testing, Material Science |

| Sample Preparation | Foundation for accurate, repeatable results | Geology, Environmental Science |

Ready to ensure the accuracy of your lab analysis?

The right grinder is the foundation of reliable results. KINTEK specializes in high-quality lab equipment and consumables, offering a range of grinders perfect for your specific sample preparation needs—whether for pharmaceuticals, food, agriculture, or materials science.

Let our experts help you select the ideal grinder to achieve perfect homogenization and maximize your lab's efficiency. Contact KINTEK today for a personalized consultation!

Visual Guide

Related Products

- Mini Planetary Ball Mill Machine for Laboratory Milling

- Liquid Nitrogen Cryogenic Grinder Mill Cryomill Airflow Ultrafine Pulverizer

- Laboratory Test Sieves and Vibratory Sieve Shaker Machine

- Powerful Plastic Crusher Machine

- High Energy Planetary Ball Mill Machine for Laboratory Horizontal Tank Type

People Also Ask

- How are planetary ball mills used for Li2ZrCl6 electrolytes? Achieve High-Conductivity Metastable Phases

- What is the function of a planetary ball mill in MAX phase powder preparation? Unlock High-Purity Atomic Homogeneity

- How does a planetary ball mill demonstrate process versatility? Powering NaNbOCl4 and NaTaOCl4 Synthesis

- What is the function of a planetary ball mill in the preparation of Li7P2S8I? Master High-Energy Mechanochemical Synthesis

- What role does a planetary ball mill play in SHS? Optimize Powder Activation for Superior Alloy Synthesis