At its core, a laboratory sieve is used to measure and separate particles based on their size. This process, known as sieve analysis, is fundamental for determining the particle size distribution of granular materials, from fine powders in pharmaceuticals to coarse aggregates in construction.

The true purpose of a lab sieve isn't just to separate big particles from small ones. It's to provide quantitative data on the distribution of different particle sizes within a sample, a critical factor for quality control and performance in countless industries.

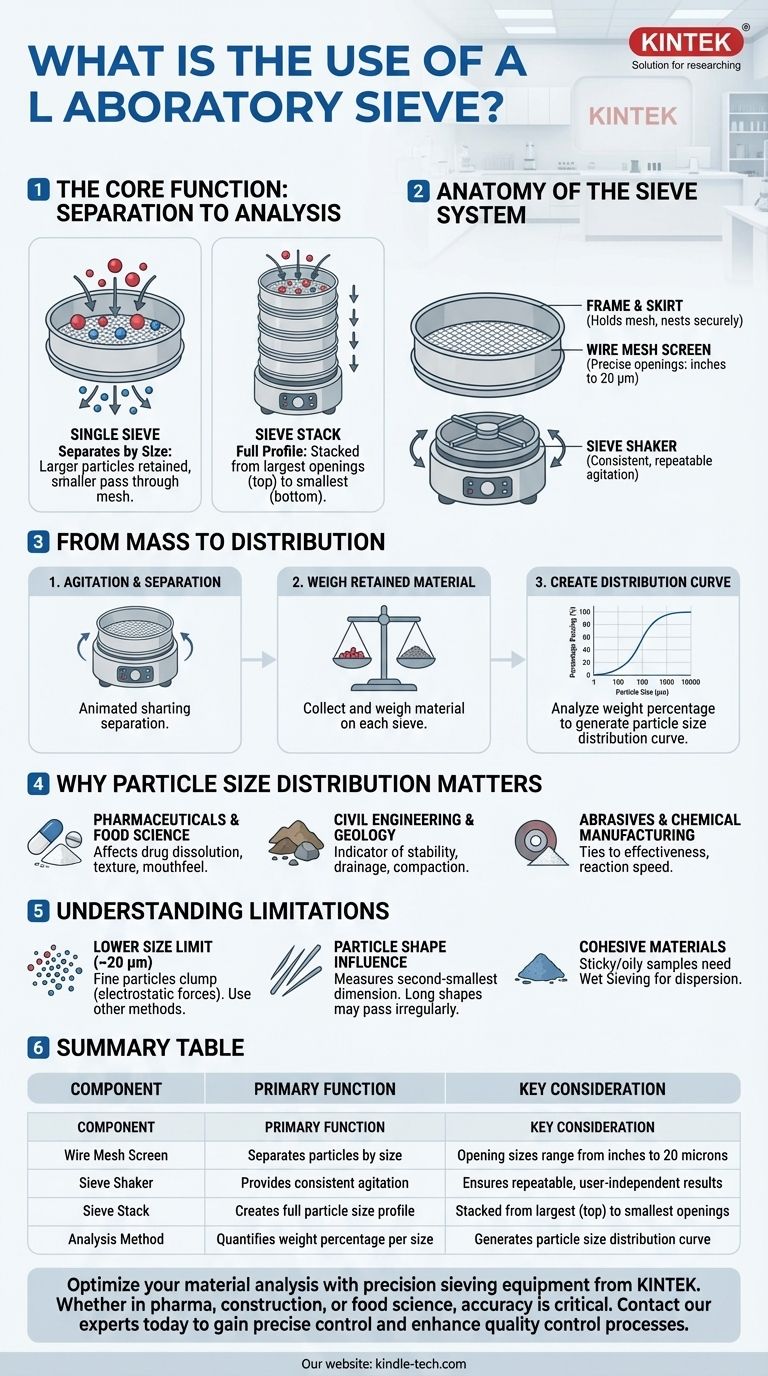

The Core Function: From Separation to Analysis

Sieve analysis is a methodical process that turns a simple mechanical separation into valuable data. The goal is to understand the composition of a sample not by its chemistry, but by its physical dimensions.

How a Single Sieve Works

The principle is straightforward. A sample of material is placed onto a screen with openings of a precise, uniform size. The sieve is then agitated, typically with a mechanical shaker.

Particles smaller than the screen's openings pass through, while larger particles are retained on top.

Stacking Sieves for a Full Profile

To get a detailed analysis, sieves are not used individually. Instead, they are stacked in a column, or "sieve stack," on a shaker.

The sieve with the largest openings is placed at the top, and each subsequent sieve below it has progressively smaller openings. A solid collection pan is placed at the very bottom.

From Mass to Distribution

After a set period of agitation, the entire stack is disassembled. The material retained on each individual sieve is carefully collected and weighed.

By calculating the weight percentage of material on each sieve, you can create a particle size distribution curve. This graph provides a detailed picture of the sample, showing the proportion of particles present in each size range.

Anatomy of the Sieve System

A laboratory sieve is more than just a screen. It's a precision instrument where each component plays a critical role in ensuring accurate and repeatable results.

The Frame and Skirt

The frame is the rigid circular ring, typically made of brass or stainless steel, that holds the mesh screen under tension.

The skirt is the edge below the frame, designed to allow the sieves to nest neatly and securely into one another without tipping.

The Wire Mesh Screen

This is the most critical part of the sieve. The mesh is a woven wire cloth made to exacting standards (like ASTM or ISO) that define the precise size of the openings.

Opening sizes can range from several inches down to just 20 microns (a human hair is about 70 microns thick), allowing for analysis of a vast array of materials.

The Sieve Shaker

While manual shaking is possible, a mechanical sieve shaker is standard for any serious lab work.

These devices provide a consistent, repeatable agitation—often a combination of tapping and vibrating motion—to ensure that particles have every opportunity to pass through the appropriate apertures. This removes user variability and ensures results are comparable between tests.

Why Particle Size Distribution Matters

Understanding the distribution of particle sizes is not an academic exercise; it directly impacts the performance, safety, and quality of products across numerous fields.

Pharmaceuticals and Food Science

In a pill, particle size affects how quickly the drug dissolves in the body, influencing its bioavailability. In food, the size of particles in flour, sugar, or spices determines texture, mouthfeel, and how well ingredients mix.

Civil Engineering and Geology

For soils and aggregates, particle size distribution is a primary indicator of stability, load-bearing capacity, and water drainage. A well-graded soil (a mix of sizes) compacts much better than a poorly-graded one (all one size).

Abrasives and Chemical Manufacturing

The effectiveness of an abrasive material is directly tied to its particle size. In chemical production, the surface area of powdered reactants—a function of particle size—can dictate the speed and efficiency of a chemical reaction.

Understanding the Limitations

While powerful, sieve analysis is not a universal solution and has important limitations to consider.

The Lower Size Limit

Sieve analysis is highly effective for particles down to about 20 microns (µm). Below this threshold, electrostatic and cohesive forces cause fine particles to clump together, preventing them from passing through the mesh. Other methods, like laser diffraction, are required for these "sub-sieve" particles.

The Influence of Particle Shape

A sieve measures a particle's second-smallest dimension. Long, needle-shaped particles may be retained on a sieve even if their narrowest dimension would allow them to pass. This can lead to a skewed representation of the actual size distribution if the particles are not roughly spherical.

The Challenge of Cohesive Materials

Materials that are sticky, oily, or prone to static cling will not separate well with dry sieving. For these, a wet sieving process—where a liquid is used to disperse the particles and wash them through the stack—is necessary. However, the liquid must not react with or dissolve the sample.

Applying This to Your Analysis

Your approach to sieve analysis depends entirely on the material you are testing and the data you need to obtain.

- If your primary focus is routine quality control for dry, granular materials (like sand, grain, or plastic pellets): A standard stack of sieves on a mechanical shaker provides reliable and repeatable data for ensuring product consistency.

- If your primary focus is analyzing fine powders for pharmaceuticals or chemicals: You must be aware of the 20-micron limit and be prepared to use alternative methods like laser diffraction for sub-sieve analysis.

- If your primary focus is characterizing soils or aggregates for construction: Sieve analysis is the industry-standard method, and the resulting particle size distribution curve is a foundational piece of data for geotechnical reports.

- If your primary focus is on materials that clump or are oily: You will need to employ wet sieving techniques to ensure the particles are properly dispersed and accurately separated.

Ultimately, using a laboratory sieve is about gaining control over your material by understanding its fundamental physical properties.

Summary Table:

| Sieve Component | Primary Function | Key Consideration |

|---|---|---|

| Wire Mesh Screen | Separates particles by size | Opening sizes range from inches to 20 microns |

| Sieve Shaker | Provides consistent agitation | Ensures repeatable, user-independent results |

| Sieve Stack | Creates full particle size profile | Stacked from largest (top) to smallest openings |

| Analysis Method | Quantifies weight percentage per size | Generates particle size distribution curve |

Optimize your material analysis with precision sieving equipment from KINTEK.

Whether you work in pharmaceuticals, construction, food science, or chemical manufacturing, accurate particle size distribution is critical for product quality, performance, and safety. KINTEK specializes in high-quality lab sieves, shakers, and consumables designed for reliable, repeatable results.

Contact our experts today to discuss your specific application. We'll help you select the right equipment to gain precise control over your material's physical properties and enhance your quality control processes.

Visual Guide

Related Products

- Laboratory Test Sieves and Vibratory Sieve Shaker Machine

- Three-dimensional electromagnetic sieving instrument

- Laboratory Vibratory Sieve Shaker Machine for Dry and Wet Three-Dimensional Sieving

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Laboratory Wet Three-Dimensional Vibratory Sieve Shaker Machine

People Also Ask

- Why is a laboratory electromagnetic vibratory sieve shaker used? Optimize Walnut Shell Chemical Pretreatment

- Why is powder classification using standard sieves essential for SHS reactions? Unlock Superior Nitriding Results

- Why is a precision vibratory sieving system important for Pt/Pd alloy analysis? Ensure Data Integrity & XRD Accuracy

- What function does a sieving system perform during HPS powder pretreatment? Ensure Uniform Particle Size Distribution

- How do high-precision sieving systems benefit zeolite preparation? Maximize Adsorption for Wastewater Treatment