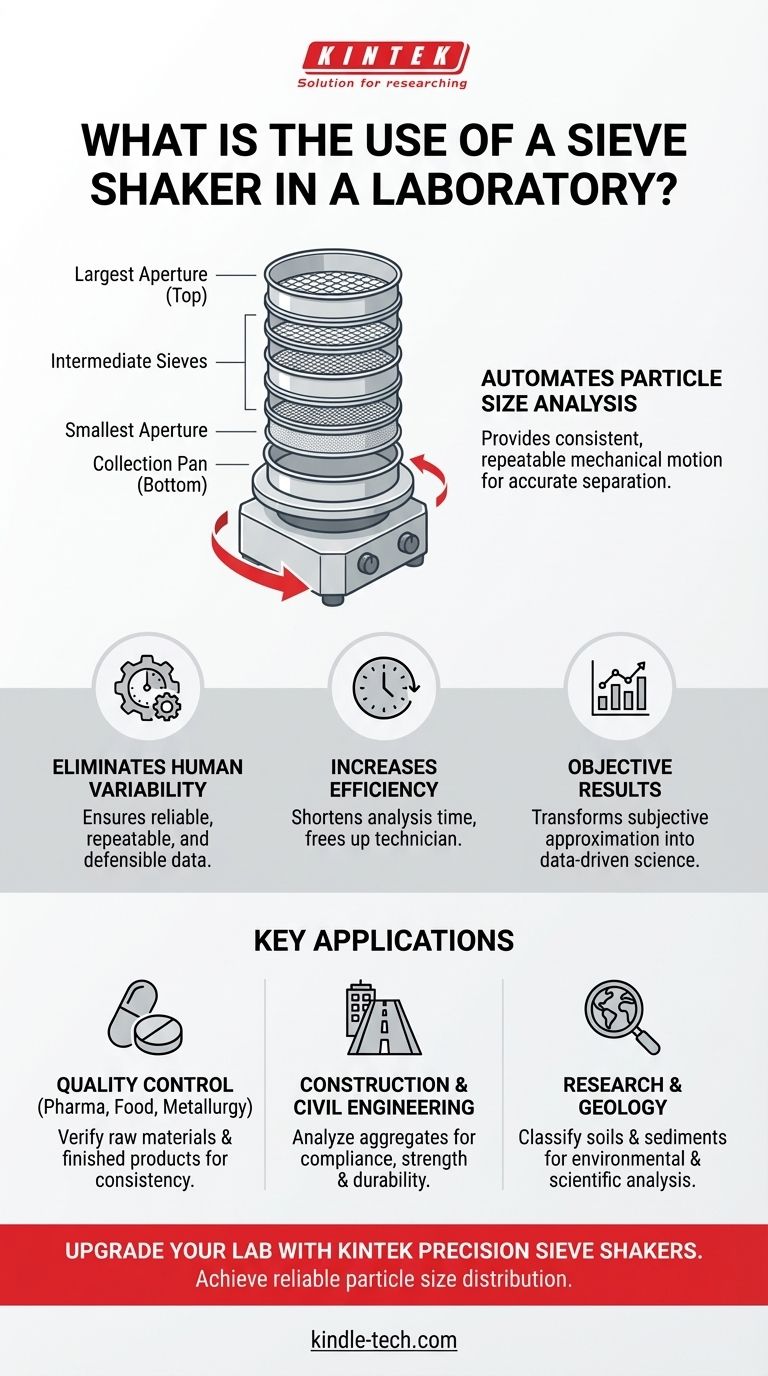

In the simplest terms, a sieve shaker is a laboratory instrument that automates the process of particle size analysis. Instead of manually shaking a stack of test sieves, the machine provides a consistent and repeatable mechanical motion to separate granular materials based on their size, ensuring accurate and efficient results.

The true purpose of a sieve shaker is not merely to shake particles; it is to eliminate human variability from the sieving process. This guarantees that particle size distribution data is reliable, repeatable, and defensible for critical quality control and research applications.

How a Sieve Shaker Achieves Particle Separation

A sieve shaker mechanizes the foundational process of sieving to produce a particle size distribution profile of a given sample. The method is straightforward but requires precision to be effective.

The Core Principle: Agitation and Segregation

The shaker imparts a specific, controlled motion—often a combination of vertical tapping and horizontal rotation—to a stack of sieves. This agitation fluidizes the material, allowing individual particles to move and present themselves to the sieve mesh openings.

Proper agitation ensures that finer particles have the opportunity to pass through to lower sieves, while larger particles are retained on upper sieves.

Stacking Sieves for Distribution Analysis

A sieve shaker is almost always used with a stack of test sieves. These are pans with a wire mesh screen of a specific, certified aperture size.

The sieves are arranged in a stack from the largest aperture size on top to the smallest on the bottom. A solid collection pan is placed at the very bottom to catch the finest particles.

Analyzing the Results

After the shaking cycle is complete, the material retained on each individual sieve is weighed. This data is used to calculate the percentage of the total sample that falls within each size range, creating a complete particle size distribution. This distribution is critical for understanding a material's physical properties.

Key Applications Across Industries

The ability to determine particle size distribution is fundamental to quality and performance in numerous fields. A sieve shaker is the standard tool for this task.

Quality Control in Manufacturing

In sectors like pharmaceuticals, food production, and metallurgy, particle size directly impacts factors like dissolution rates, texture, flowability, and reactivity. Sieve shakers are used to verify that raw materials and finished products meet precise specifications.

Construction and Civil Engineering

The strength and durability of materials like concrete, asphalt, and soil aggregates depend on a specific blend of particle sizes. Sieve shakers are used to analyze these materials to ensure they comply with construction and safety standards.

Research and Geology

In scientific research and geology, particle analysis helps classify soils, sediments, and other geological samples. This data is essential for understanding environmental processes and classifying raw materials in mining and exploration.

Understanding the Trade-offs: Sieve Shaker vs. Manual Sieving

While manual sieving is possible, it is rarely acceptable for professional applications due to its inherent flaws. A mechanical shaker directly addresses these shortcomings.

The Problem with Manual Sieving

Hand sieving is subject to immense operator variability. The force, duration, and type of shaking motion will differ from person to person and even from test to test with the same person. This makes it impossible to achieve truly repeatable results.

The Advantage of Repeatability

A sieve shaker eliminates this variability. By using a precisely controlled motion and a set timer, it ensures that every sample is subjected to the exact same conditions. This repeatability is the cornerstone of reliable quality control and valid scientific comparison.

The Benefit of Efficiency

Automating the process frees up valuable technician time and significantly shortens the analysis period. A machine can complete a thorough separation in minutes, a task that would be far more laborious and less effective if done by hand.

Making the Right Choice for Your Goal

Using a sieve shaker is about standardizing your measurement process. Your specific goal will determine how you interpret the results.

- If your primary focus is process quality control: Use the sieve shaker to verify that incoming raw materials and outgoing finished products consistently meet a predefined particle size distribution.

- If your primary focus is foundational research: Use the shaker to accurately characterize new materials or understand how particle size affects a particular chemical or physical process.

- If your primary focus is compliance and standards: Employ a sieve shaker to generate the official data required to certify that your materials (e.g., construction aggregates, soils) meet industry or government regulations.

Ultimately, a sieve shaker transforms particle analysis from a subjective approximation into an objective, data-driven science.

Summary Table:

| Application | Purpose | Key Benefit |

|---|---|---|

| Quality Control (Pharma, Food) | Verify raw materials & finished products | Ensures consistent product performance |

| Construction & Civil Engineering | Analyze aggregates for compliance | Guarantees material strength & durability |

| Research & Geology | Classify soils and sediments | Provides accurate data for scientific analysis |

Upgrade your lab's particle analysis with KINTEK's precision sieve shakers.

Tired of inconsistent manual sieving? KINTEK specializes in high-quality lab equipment that delivers the repeatable, accurate particle size data your quality control and research demand. Our sieve shakers are designed to save you time, eliminate operator variability, and generate defensible results for compliance and R&D.

Ready to achieve reliable particle size distribution? Contact our experts today to find the perfect sieve shaker for your laboratory's needs!

Visual Guide

Related Products

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Laboratory Oscillating Orbital Shaker

- Shaking Incubators for Diverse Laboratory Applications

- Laboratory Vortex Mixer Orbital Shaker Multifunctional Rotation Oscillation Mixer

- Double Plate Heating Press Mold for Lab

People Also Ask

- What role does a laboratory vibrating sieve shaker play in the LiFePO4 powder processing workflow? Ensure Batch Quality

- What is the principle of vibratory sieve shaker? Achieve Accurate Particle Size Analysis

- What are the components of a sieving machine? Unlock the Anatomy of Precision Particle Separation

- What is the amplitude of a sieve shaker? A Guide to Optimizing Particle Separation

- What are the disadvantages of sieve machine? Key Limitations in Particle Size Analysis