At its core, twin screw compounding is a sophisticated manufacturing process used to melt and intensively mix polymers with a wide range of additives like fillers, reinforcements, and colorants. This process occurs inside a specialized machine called a twin-screw extruder (TSE), which uses two intermeshing, co-rotating screws to create new plastic compounds with tailored properties.

Twin screw compounding is not just simple mixing. It is a highly engineered and versatile platform that provides precise control over temperature, shear, and residence time, enabling the creation of complex, high-performance materials that are impossible to produce with simpler methods.

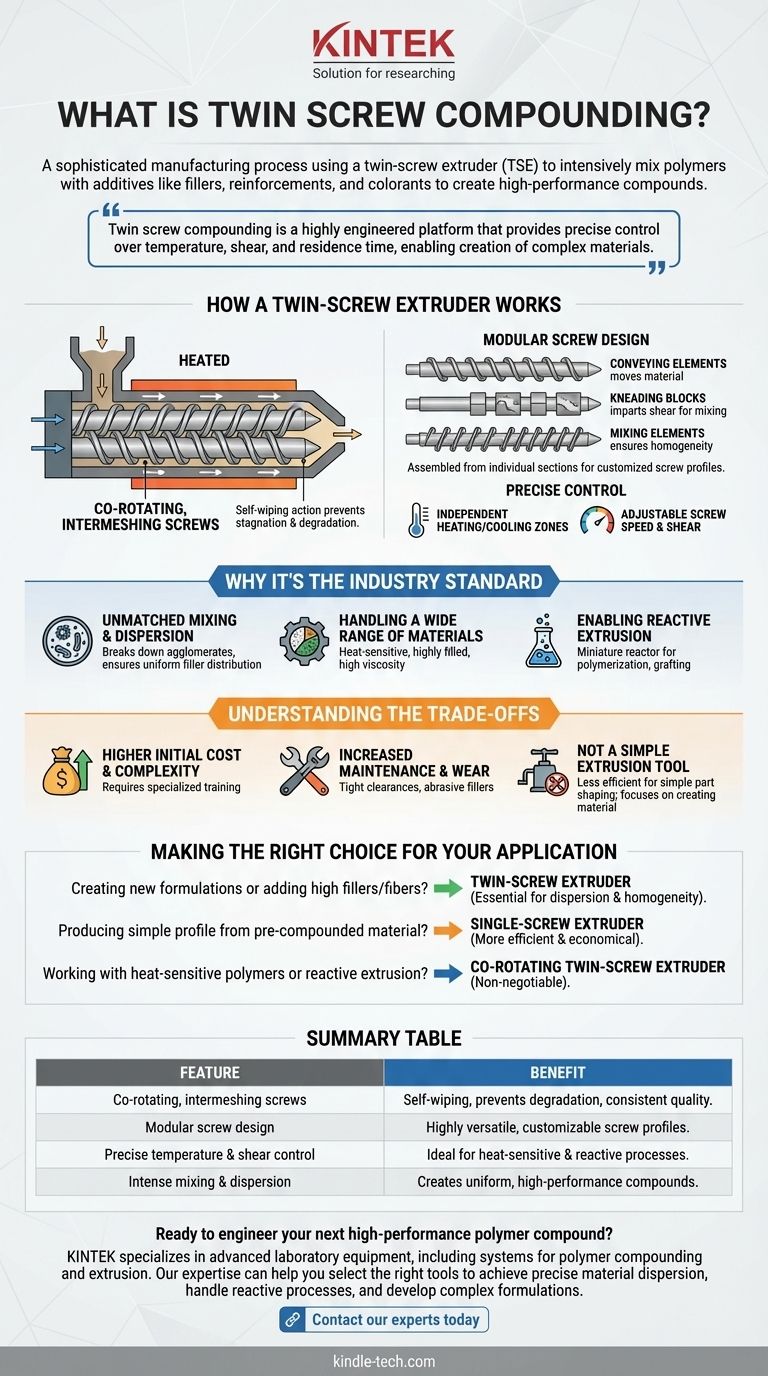

How a Twin-Screw Extruder Works

The magic of twin screw compounding lies in the design of the extruder itself. Unlike a single-screw extruder which primarily acts as a pump, the twin-screw system is a highly active and configurable mixer.

The Two Intermeshing Screws

The system is built around two screws that are positioned side-by-side inside a heated barrel. They rotate in the same direction (co-rotating) and are designed to intermesh with each other.

This intermeshing geometry creates a self-wiping action. As the screws turn, the flight of one screw cleans the channel of the other, preventing material from stagnating, burning, or degrading. This is critical for process stability and product quality.

Modular Screw Design: The Key to Versatility

The screws are not single, continuous pieces. Instead, they are assembled from a series of individual sections called screw elements, which are slid onto a splined shaft.

Each element has a specific function. Conveying elements move the material forward, kneading blocks impart intense shear for mixing and dispersion, and mixing elements ensure the final melt is homogeneous.

By arranging these elements in a specific sequence, an engineer can design a screw profile that is perfectly optimized for a particular polymer system and desired outcome. This modularity is what makes the TSE so incredibly versatile.

Precise Control Over the Process

The TSE offers operators multiple levers to control the material transformation. The barrel is divided into several independent heating and cooling zones, allowing for a precise temperature profile along the length of the process.

Combined with the ability to adjust screw speed, this gives operators unparalleled control over the amount of energy and shear imparted to the material at every stage.

Why It's the Industry Standard

The unique capabilities of the TSE make it the preferred choice for nearly all demanding polymer compounding applications.

Unmatched Mixing and Dispersion

The intense shear generated in the kneading zones is highly effective at breaking down agglomerates of fillers (like carbon black or talc) and ensuring fibers (like glass or carbon) are thoroughly and uniformly dispersed throughout the polymer matrix. This directly translates to improved mechanical properties and performance.

Handling a Wide Range of Materials

The positive conveyance and self-wiping action make the TSE ideal for processing difficult materials, including heat-sensitive polymers, highly filled compounds, and materials with very high viscosity.

Enabling Reactive Extrusion

The extruder can be used as a miniature, continuous chemical reactor. By injecting liquids or adding reactive agents, processes like polymerization, grafting, or controlled degradation can be performed directly within the machine, creating unique and high-value materials.

Understanding the Trade-offs

While powerful, the twin-screw extruder is not a universal solution. Its sophistication comes with specific challenges that must be considered.

Higher Initial Cost and Complexity

Twin-screw extruders are significantly more expensive and mechanically complex than their single-screw counterparts. Operating them effectively requires a higher level of training and process knowledge.

Increased Maintenance and Wear

The tight clearances between the screws and the barrel (often less than a millimeter) are critical for performance but also make the system susceptible to wear, especially when processing abrasive fillers. Regular monitoring and replacement of worn elements are essential maintenance costs.

Not a Simple Extrusion Tool

A TSE is an exceptional compounder but a less efficient pump. For simple, high-volume manufacturing of a finished part like a pipe or sheet from a pre-made pellet, a single-screw extruder is almost always the more cost-effective choice. The TSE is for creating the material, not just shaping it.

Making the Right Choice for Your Application

Selecting the right technology depends entirely on your end goal.

- If your primary focus is creating new material formulations or adding high levels of fillers/fibers: A twin-screw extruder is the essential tool for achieving the required dispersion and homogeneity.

- If your primary focus is producing a simple profile (pipe, sheet, film) from a pre-compounded raw material: A single-screw extruder is the more efficient and economical choice for the job.

- If your primary focus is working with heat-sensitive polymers or performing reactive extrusion: The superior control and self-wiping design of a co-rotating twin-screw extruder are non-negotiable.

Ultimately, mastering twin screw compounding allows you to move beyond simply processing plastics and begin engineering materials with precision.

Summary Table:

| Feature | Benefit |

|---|---|

| Co-rotating, intermeshing screws | Self-wiping action prevents material degradation and ensures consistent quality. |

| Modular screw design | Highly versatile; screw profiles can be customized for specific materials and outcomes. |

| Precise temperature and shear control | Ideal for heat-sensitive polymers and reactive extrusion processes. |

| Intense mixing and dispersion | Creates uniform, high-performance compounds with superior mechanical properties. |

Ready to engineer your next high-performance polymer compound?

KINTEK specializes in advanced laboratory equipment, including systems for polymer compounding and extrusion. Our expertise can help you select the right tools to achieve precise material dispersion, handle reactive processes, and develop complex formulations.

Contact our experts today to discuss how we can support your laboratory's compounding and material development needs.

Visual Guide

Related Products

- Laboratory Test Sieves and Sieving Machines

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Anti-Cracking Press Mold for Lab Use

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

People Also Ask

- How is a vibratory sieve shaker used in the particle size analysis of mechanically alloyed powders? Expert Guide

- What is the role of standard sieves in gold scrap leaching kinetic studies? Ensure Precision in Particle Classification

- Why is a precision vibrating sieve shaker essential for metal leaching research? Optimize Your Particle Size Analysis

- What are the specifications for test sieves? A Guide to ASTM & ISO Standards for Accurate Particle Analysis

- What is the primary function of a mechanical sieve shaker for biomass analysis? Optimize Particle Size Distribution