In laboratory settings, a range of specialized mills are used for grinding samples, with the most common being ball mills, vibratory (or swing) mills, planetary mills, and cutting mills. The specific equipment chosen depends entirely on the sample's properties—such as its hardness and texture—and the final particle size required for analysis. Jaw crushers are also used for the preliminary coarse crushing of larger, very hard materials.

The central challenge of lab grinding is not finding a machine that grinds, but selecting a machine whose grinding mechanism—be it impact, friction, vibration, or cutting—is perfectly matched to your sample's unique physical properties and your analytical goals.

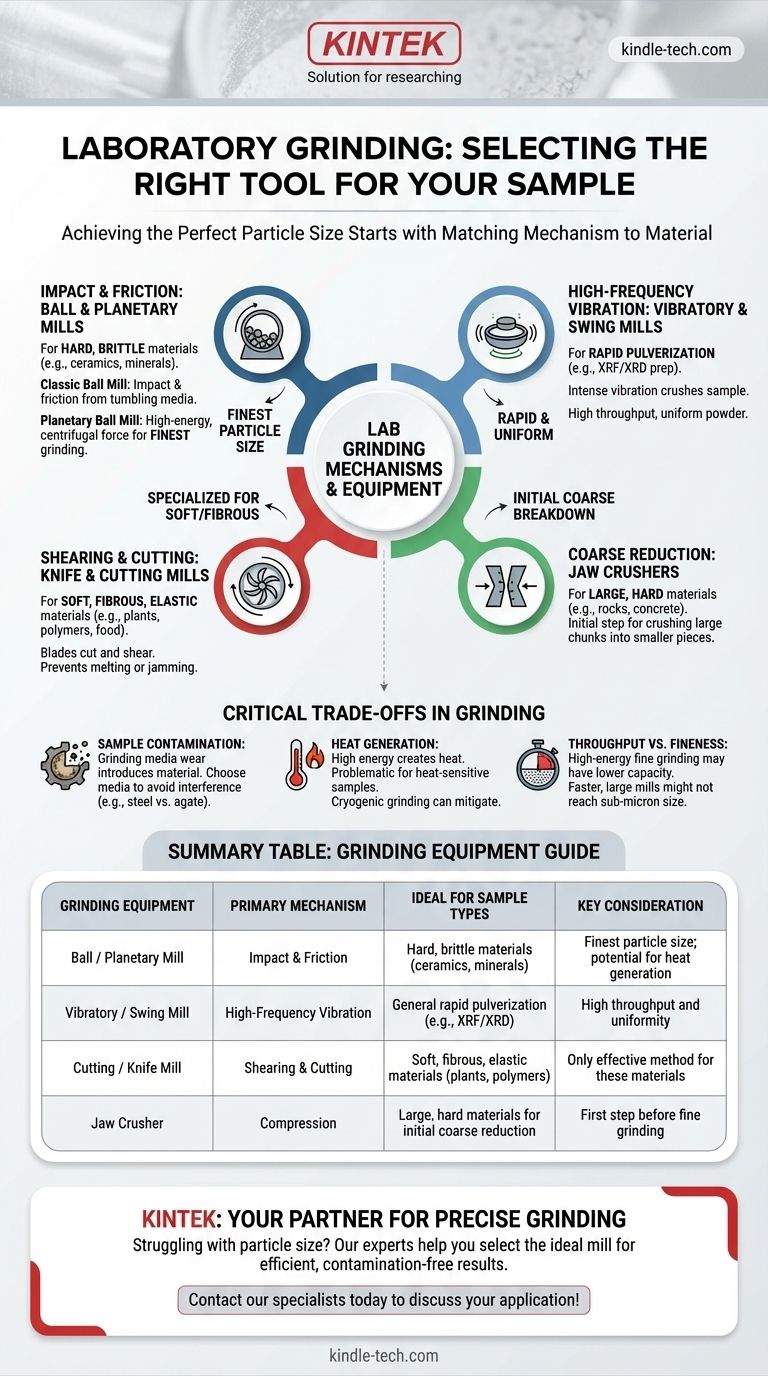

The Core Grinding Mechanisms Explained

To choose the right tool, you must first understand how they work. Laboratory grinders operate on a few key principles, each suited for different types of materials.

Impact and Friction: Ball and Planetary Mills

A ball mill is a classic and versatile tool. It consists of a hollow jar or drum filled with the sample and grinding media, typically ceramic or metal balls. As the jar rotates, the balls cascade and tumble, grinding the sample through a combination of impact and friction.

A planetary ball mill is a high-energy version of this concept. Multiple grinding jars are mounted on a large "sun wheel" that rotates in one direction while the jars themselves rotate in the opposite direction. This creates immense centrifugal forces, resulting in much faster and finer grinding than a standard ball mill. These are ideal for hard, brittle materials.

High-Frequency Vibration: Vibratory and Swing Mills

Vibratory mills, often called "swing mills" or "shatterboxes," are workhorses in many analytical labs. The sample is placed in a sealed grinding dish, usually with a puck and ring or with several balls. The entire assembly is then subjected to intense, high-frequency vibration.

This rapid shaking motion causes the grinding media to collide with the sample thousands of times per minute, pulverizing it very quickly. This method is exceptionally efficient for achieving a fine, uniform powder, making it popular for preparing samples for X-ray fluorescence (XRF) or X-ray diffraction (XRD).

Shearing and Cutting: Knife and Cutting Mills

For materials that are soft, fibrous, or elastic, impact-based methods are ineffective. These materials (like plant tissue, polymers, or food products) require a different approach.

Cutting and knife mills function much like a high-speed kitchen blender. A set of sharp, rotating blades cuts and shears the material against a stationary cutting edge or a sieve. This is the only effective method for homogenizing samples that would otherwise deform, melt, or jam a traditional ball or vibratory mill.

Coarse Reduction: Jaw Crushers

When your starting sample is too large to fit in a fine-grinding mill, you need a preliminary step. A jaw crusher is designed for this purpose. It uses two heavy jaws—one fixed and one that moves back and forth—to compress and break down large, hard materials like rocks, ores, or concrete into smaller, more manageable pieces suitable for further processing.

Understanding the Critical Trade-offs

Selecting a grinder involves more than just matching the material type. You must also consider the practical implications of each method.

Sample Contamination

This is a primary concern in trace element analysis. The grinding media (balls, jars, pucks, jaws) will inevitably wear down, introducing small amounts of their own material into your sample. Using steel media will add iron and chromium; tungsten carbide will add tungsten; agate is low-contamination but brittle. You must choose a grinding material that will not interfere with your subsequent analysis.

Heat Generation

All grinding is a high-energy process that generates heat. For heat-sensitive samples, such as certain polymers or biological materials with volatile compounds, this can be a significant problem. Some methods, like cryogenic grinding (where the sample is chilled with liquid nitrogen), can mitigate this, but it adds complexity.

Throughput vs. Fineness

There is often a trade-off between how fast you can process samples and how fine you can make them. High-energy planetary mills achieve very fine particle sizes but may have a smaller capacity and require longer cooling times between runs. A large vibratory mill can process larger samples more quickly but may not reach the same sub-micron fineness.

How to Select the Right Grinder

Your choice should be guided by a clear understanding of your sample and your goal.

- If your sample is hard and brittle (e.g., ceramics, minerals, glass): A planetary ball mill is your best choice for achieving the finest particles, while a standard ball mill is a reliable option for general use.

- If your sample is soft or fibrous (e.g., plant tissue, polymers, paper): A cutting or knife mill is essential, as other methods will fail.

- If you need rapid, high-throughput pulverization for analysis (e.g., preparing pressed pellets for XRF): A vibratory swing mill is the industry standard for speed and consistency.

- If you are starting with large, tough chunks of material (e.g., rocks from the field): Begin with a jaw crusher to perform primary size reduction before moving to a finer mill.

Ultimately, selecting the correct grinding equipment is about precisely matching the tool's mechanical action to your sample's physical properties.

Summary Table:

| Grinding Equipment | Primary Mechanism | Ideal For Sample Types | Key Consideration |

|---|---|---|---|

| Ball / Planetary Mill | Impact & Friction | Hard, brittle materials (ceramics, minerals) | Finest particle size; potential for heat generation |

| Vibratory / Swing Mill | High-Frequency Vibration | General rapid pulverization (e.g., for XRF/XRD) | High throughput and uniformity |

| Cutting / Knife Mill | Shearing & Cutting | Soft, fibrous, elastic materials (plants, polymers) | Only effective method for these materials |

| Jaw Crusher | Compression | Large, hard materials for initial coarse reduction | First step before fine grinding |

Struggling to achieve the perfect particle size for your analysis? The right lab grinder is critical for accurate results. KINTEK specializes in lab equipment and consumables, serving all your laboratory needs. Our experts can help you select the ideal mill—whether it's a high-energy planetary mill for hard ceramics or a gentle knife mill for sensitive polymers—ensuring your sample preparation is efficient and contamination-free.

Contact our grinding specialists today to discuss your specific application and request a personalized equipment recommendation!

Visual Guide

Related Products

- Laboratory Planetary Ball Mill Cabinet Planetary Ball Milling Machine

- Laboratory Single Horizontal Jar Mill

- Three-dimensional electromagnetic sieving instrument

- Laboratory Jaw Crusher

- Laboratory Hybrid Tissue Grinding Mill

People Also Ask

- What is a hammer mill used for in pharmaceuticals? Achieve Precise Particle Size Control for Better Drug Efficacy

- What is the difference between a hammer mill and a cutter mill? Choose the Right Size Reduction Method

- Why is an agate mortar and pestle preferred for melamine condensates? Achieve Molecular Purity in Nanomaterial Synthesis

- Why is grinding and sieving equipment used for waste tire hydrothermal liquefaction? Maximize Your Reaction Efficiency

- What is the function of an ultrasonic homogenizer in high-entropy metallic glass synthesis? Key to Stoichiometric Control

- What are the factors that affect milling machine? Master the Trade-offs for Peak Performance

- Why is grinding important in sample preparation? Ensure Accurate & Reliable Analytical Results

- What kind of balls are used in ball mills? Optimize Your Grinding with the Right Media