For a pyrolysis reactor, the material selection is a critical engineering choice balancing cost against performance under extreme conditions. Reactors are typically made from specific grades of carbon steel boiler plates, such as Q245R and Q345R, or more resilient alloys like 304 and 316 stainless steel. The final decision is dictated by the chemical makeup of the feedstock and the desired operational lifespan of the unit.

The core decision in selecting a reactor material comes down to a trade-off between the upfront cost of carbon steel and the long-term durability and corrosion resistance of stainless steel. Your specific feedstock is the single most important factor that should guide this choice.

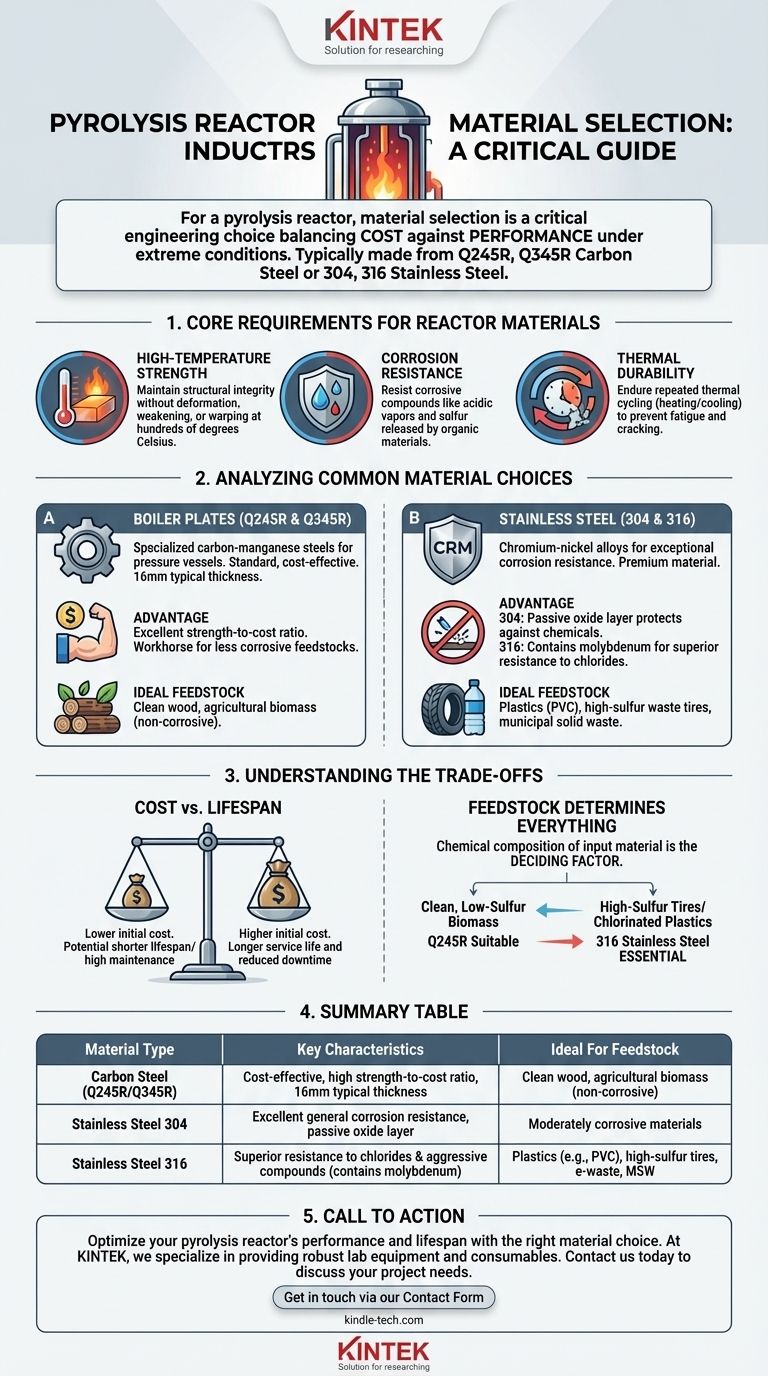

The Core Requirements for Reactor Materials

Pyrolysis is the thermal decomposition of materials at elevated temperatures in an inert atmosphere. The material containing this reaction must withstand significant stress.

High-Temperature Strength

A pyrolysis reactor operates at high temperatures, often several hundred degrees Celsius. The chosen material must maintain its structural integrity and not deform, weaken, or warp under this constant thermal load.

Corrosion Resistance

When organic materials are heated, they can release a variety of corrosive compounds, including acidic vapors and sulfur compounds. The reactor's inner wall must be able to resist this chemical attack to prevent premature failure.

Thermal Durability

The reactor must endure repeated thermal cycling—heating up for operation and cooling down for maintenance. The material must resist thermal fatigue and cracking that can result from this constant expansion and contraction.

Analyzing the Common Material Choices

The two primary classes of materials used each offer a distinct set of advantages suited for different operational contexts.

Boiler Plates (Q245R & Q345R)

These are specialized carbon-manganese steels designed for building pressure vessels and boilers. They represent the standard, cost-effective choice for many pyrolysis systems.

Their primary advantage is an excellent strength-to-cost ratio. They provide the necessary high-temperature strength for many applications, with a typical thickness of 16mm ensuring structural robustness. They are the workhorse material for processing less corrosive feedstocks like clean wood or agricultural biomass.

Stainless Steel (304 & 316)

These are chromium-nickel alloys known for their exceptional resistance to corrosion and rust. They are considered the premium material for more demanding pyrolysis applications.

The high chromium content in 304 stainless steel creates a passive, self-healing oxide layer that protects it from a wide range of chemical attacks.

For even harsher environments, 316 stainless steel is used. It includes molybdenum, which significantly enhances its resistance to chlorides and other aggressive compounds often found when processing plastics (like PVC) or municipal solid waste.

Understanding the Trade-offs

Choosing a material is not just about performance; it's about aligning technical requirements with your budget and operational goals.

Cost vs. Lifespan

Carbon steel boiler plate offers a much lower upfront investment, making it attractive for budget-constrained projects or applications with non-corrosive feedstock.

However, if the feedstock is even mildly corrosive, the initial savings can be quickly erased by higher maintenance costs and a shorter reactor lifespan. Stainless steel's higher initial cost is often justified by its significantly longer service life and reduced downtime in demanding applications.

Feedstock Determines Everything

The chemical composition of your input material is the deciding factor.

Processing clean, low-sulfur biomass may be perfectly suitable for a Q245R reactor. In contrast, attempting to process high-sulfur waste tires or chlorinated plastics in the same reactor would lead to rapid corrosion and failure. For these aggressive feedstocks, 316 stainless steel is not a luxury but a necessity.

Making the Right Choice for Your Operation

The optimal material is dictated entirely by your specific operational and financial goals.

- If your primary focus is cost-efficiency with non-corrosive feedstock (e.g., clean wood, paper): Carbon steel boiler plates like Q245R offer the best balance of performance and initial investment.

- If your primary focus is processing corrosive materials (e.g., plastics, e-waste, high-sulfur tires): Investing in 304 or, more robustly, 316 stainless steel is essential to ensure reactor longevity and operational safety.

- If your primary focus is producing high-purity oils or specialty chemicals: The non-reactive surface of stainless steel is the superior choice to prevent product contamination from metal leaching.

Ultimately, a thorough chemical analysis of your feedstock is the most critical step in selecting a durable and effective reactor material.

Summary Table:

| Material Type | Key Characteristics | Ideal For Feedstock |

|---|---|---|

| Carbon Steel (Q245R/Q345R) | Cost-effective, high strength-to-cost ratio, 16mm typical thickness | Clean wood, agricultural biomass (non-corrosive) |

| Stainless Steel 304 | Excellent general corrosion resistance, passive oxide layer | Moderately corrosive materials |

| Stainless Steel 316 | Superior resistance to chlorides & aggressive compounds (contains molybdenum) | Plastics (e.g., PVC), high-sulfur tires, e-waste, MSW |

Optimize your pyrolysis reactor's performance and lifespan with the right material choice. The selection between carbon steel and stainless steel is critical for balancing cost, durability, and resistance to corrosive feedstocks. At KINTEK, we specialize in providing robust lab equipment and consumables, including reactors designed for demanding thermal processes. Our experts can help you analyze your specific feedstock and operational goals to recommend the ideal reactor material, ensuring long-term reliability and efficiency for your laboratory. Contact us today to discuss your project needs and let KINTEK be your partner in advanced laboratory solutions. Get in touch via our Contact Form

Visual Guide

Related Products

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Stainless High Pressure Autoclave Reactor Laboratory Pressure Reactor

- Mini SS High Pressure Autoclave Reactor for Laboratory Use

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

People Also Ask

- What is the contribution of a hydrothermal reactor to graded pore construction? Precision Templates for TAS

- What role does an autoclave play in simulating PWR conditions? Advanced Material Validation for Nuclear Safety

- Why are high-pressure autoclaves essential for preparing bio-based polyamide curing agents from dimeric acid?

- What is the role of high-pressure reactors in the study of alloy oxidation? Essential Tools for Supercritical Research

- How does a high-pressure reactor demonstrate its value in accelerated aging? Predict Catalyst Durability Fast