The most common materials used for coating carbide tools are ceramic compounds applied in thin layers, primarily Titanium Nitride (TiN), Titanium Aluminum Nitride (TiAlN), and Titanium Carbonitride (TiCN). These coatings create an extremely hard, lubricious, and heat-resistant barrier between the cutting tool and the workpiece, dramatically improving performance and tool life.

The core principle is not about a single "best" material, but about selecting a specific coating system whose properties—hardness, thermal stability, and lubricity—are precisely matched to the machining operation and the material being cut.

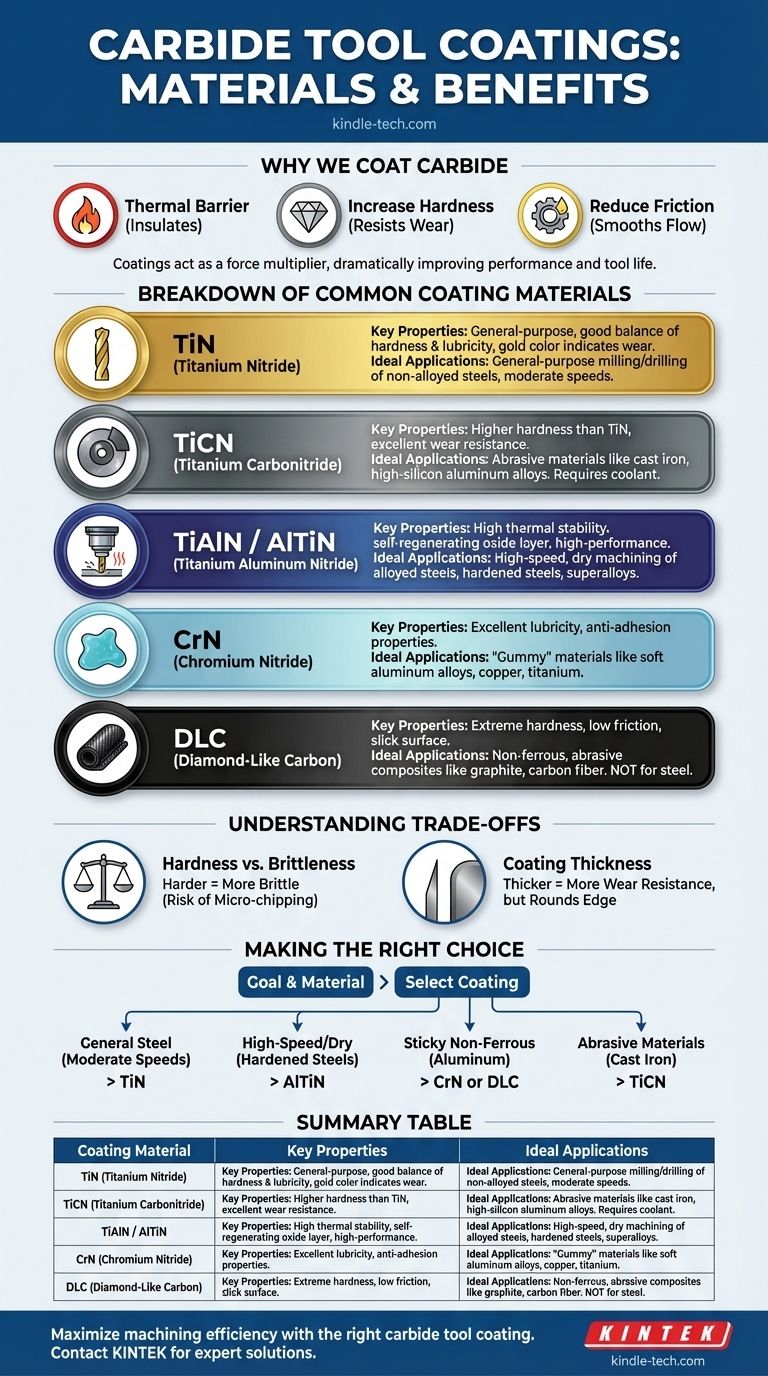

Why We Coat Carbide in the First Place

Carbide is inherently hard and wear-resistant, but modern machining pushes tools to their absolute limits. Coatings act as a force multiplier, providing critical advantages that the raw carbide substrate cannot deliver on its own.

The Thermal Barrier Effect

High-speed machining generates immense heat at the cutting edge. This heat can soften the carbide substrate and accelerate wear.

A ceramic coating acts as an insulator, preventing much of that heat from reaching the carbide. This is especially true for coatings containing aluminum, like TiAlN.

Increasing Surface Hardness

Coatings are significantly harder than the underlying carbide. This ultra-hard surface provides exceptional resistance to abrasive wear, which is common when cutting materials like cast iron or high-silicon aluminum.

Reducing Friction

A lower coefficient of friction means less heat generation and smoother chip evacuation. Coatings like Chromium Nitride (CrN) or Diamond-Like Carbon (DLC) provide a highly lubricious surface that prevents material from sticking to the tool, a phenomenon known as "built-up edge."

A Breakdown of Common Coating Materials

While there are many specialized coatings, a few dominate the industry. Understanding their individual strengths is key to selecting the right tool for the job.

TiN (Titanium Nitride)

Key Properties: This is the foundational, general-purpose coating, easily identified by its gold color. It offers a good balance of hardness and lubricity.

Ideal Applications: Excellent for general-purpose milling and drilling of non-alloyed steels and softer materials where cutting speeds and temperatures are moderate. Its distinct color also provides a clear visual indicator of tool wear.

TiCN (Titanium Carbonitride)

Key Properties: By adding carbon to the TiN structure, TiCN becomes significantly harder and more wear-resistant.

Ideal Applications: It excels in machining abrasive materials like cast iron and high-silicon aluminum alloys. It's also effective on stainless steels, but typically requires coolant due to lower thermal stability compared to TiAlN.

TiAlN / AlTiN (Titanium Aluminum Nitride)

Key Properties: These are high-performance workhorses for modern machining. The addition of aluminum creates a protective, self-regenerating layer of aluminum oxide at high temperatures.

Ideal Applications: Perfect for high-speed, dry machining of alloyed steels, hardened steels, and superalloys like Inconel. AlTiN, with a higher aluminum-to-titanium ratio, offers even greater thermal stability for the most demanding applications.

CrN (Chromium Nitride)

Key Properties: CrN is not as hard as titanium-based coatings, but it has excellent lubricity and anti-adhesion properties.

Ideal Applications: It is the preferred choice for "gummy" or sticky materials that tend to build up on the cutting edge, such as soft aluminum alloys, copper, and titanium.

DLC (Diamond-Like Carbon)

Key Properties: DLC coatings are exceptionally hard and have an extremely low coefficient of friction, creating a slick, graphite-like surface.

Ideal Applications: Unbeatable for machining non-ferrous and abrasive composite materials like high-silicon aluminum, graphite, and carbon fiber. Note: DLC should not be used on steel, as the high heat can cause a chemical reaction that degrades the coating.

Understanding the Trade-offs

Choosing a coating is a matter of balancing competing factors. There is no single coating that is superior in all situations.

Hardness vs. Brittleness

An extremely hard coating can sometimes be more brittle. A coating that is too brittle can micro-chip on a sharp cutting edge, especially during interrupted cuts (like milling), leading to premature tool failure.

Coating Thickness

A thicker coating provides more wear resistance, but it can also round the cutting edge. For finishing operations that require a very sharp edge to achieve a fine surface finish, a thinner coating is often preferable.

Cost vs. Performance

Advanced multi-layer coatings like AlTiN are more expensive to produce than basic TiN. The goal is to select a coating that provides a significant enough increase in tool life and productivity to justify the higher initial cost.

Making the Right Choice for Your Application

Selecting the correct coating begins with a clear understanding of your goal and the material you are machining.

- If your primary focus is general-purpose machining of steels at moderate speeds: TiN is a reliable and cost-effective starting point.

- If your primary focus is high-speed or dry machining of hardened steels and superalloys: AlTiN is the superior choice due to its exceptional thermal stability.

- If your primary focus is machining "sticky" non-ferrous materials like aluminum: CrN or DLC will prevent material buildup and improve surface finish.

- If your primary focus is cutting highly abrasive materials like cast iron: The superior hardness of TiCN will provide the best resistance to abrasive wear.

Ultimately, viewing a coating not as a feature but as an integral component of the cutting system empowers you to maximize performance and efficiency.

Summary Table:

| Coating Material | Key Properties | Ideal Applications |

|---|---|---|

| TiN (Titanium Nitride) | Good hardness & lubricity, gold color | General-purpose milling/drilling of non-alloyed steels |

| TiCN (Titanium Carbonitride) | Higher hardness than TiN, wear-resistant | Abrasive materials (cast iron, high-silicon aluminum) |

| TiAlN / AlTiN (Titanium Aluminum Nitride) | High thermal stability, self-regenerating oxide layer | High-speed/dry machining of hardened steels & superalloys |

| CrN (Chromium Nitride) | Excellent lubricity, anti-adhesion | Sticky materials (aluminum, copper, titanium) |

| DLC (Diamond-Like Carbon) | Extreme hardness, low friction | Non-ferrous & abrasive composites (graphite, carbon fiber) |

Maximize your machining efficiency with the right carbide tool coating. At KINTEK, we specialize in lab equipment and consumables, serving all your laboratory needs. Our experts can help you select the optimal coating solution to extend tool life, improve performance, and reduce costs for your specific application. Contact us today to discuss your requirements and discover how our solutions can enhance your operations!

Visual Guide

Related Products

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

People Also Ask

- What is microwave plasma CVD? A Guide to High-Purity Diamond and Material Synthesis

- What is the role of the HF-CVD system in preparing BDD electrodes? Scalable Solutions for Boron-Doped Diamond Production

- What is the hot filament chemical vapour deposition of diamond? A Guide to Synthetic Diamond Coating

- What are the advantages of using HFCVD for BDD electrodes? Scaling Industrial Diamond Production Efficiently

- What machine is used to make lab-grown diamonds? Discover the HPHT & CVD Technologies