At its core, an ultra-low temperature (ULT) freezer's insulation is built from high-density polyurethane foam, often supplemented with advanced vacuum-insulated panels (VIPs). This insulation is not merely a feature; it is the freezer's primary defense against the constant infiltration of ambient heat. Its effectiveness is directly responsible for maintaining the extreme cold necessary for sample preservation, ensuring temperature stability, and reducing the operational strain on the entire cooling system.

The battle to maintain -80°C is fundamentally a battle against heat. Superior insulation is the most critical factor in winning that fight, directly impacting sample integrity, energy consumption, and the longevity of the freezer itself.

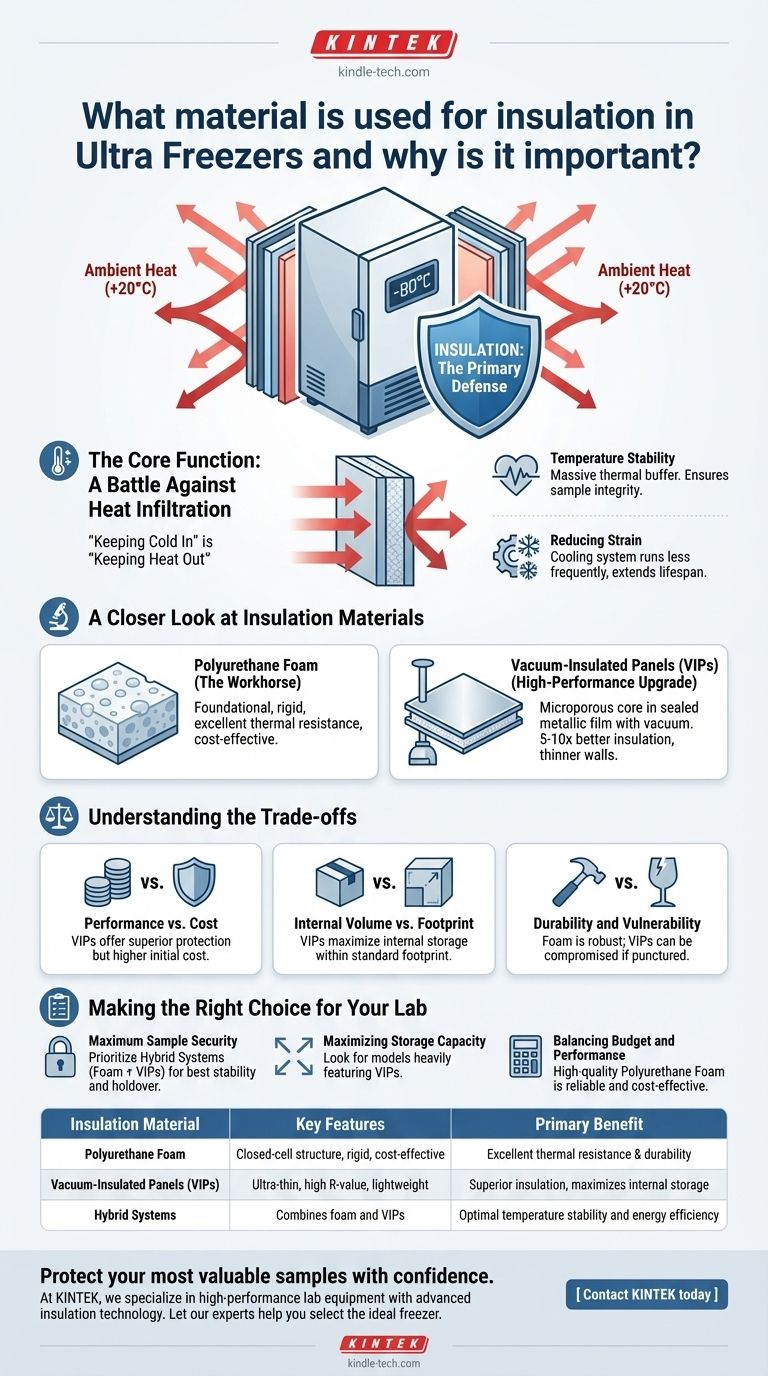

The Core Function: A Battle Against Heat Infiltration

To understand why insulation is so critical, it's essential to reframe the problem. A freezer doesn't "create cold"; it actively removes heat. Insulation is the barrier that slows down the rate at which new heat can enter from the surrounding room.

Why "Keeping Cold In" Is Really "Keeping Heat Out"

Heat naturally moves from a warmer area to a colder one. Your freezer cabinet is a -80°C environment sitting in a room that is likely +20°C. Without a barrier, heat would rush in, and the internal temperature would quickly rise.

Insulation, like polyurethane foam, works by trapping gas in millions of tiny, separate pockets. This structure makes it very difficult for heat energy to conduct its way from the outer wall of the freezer to the inner chamber.

The Critical Role of Temperature Stability

For sensitive biological samples, vaccines, and reagents, even minor temperature fluctuations can cause degradation and render them useless. High-quality insulation acts as a massive thermal buffer.

This high insulation coefficient ensures that if a door is opened or if there is a temporary power failure, the internal temperature rises much more slowly. This provides a crucial window of time to protect invaluable assets.

Reducing Strain on the Cooling System

The freezer's refrigeration system—its compressors and condensers—only runs when it needs to remove heat that has penetrated the cabinet.

Better insulation means less heat gets in per hour. This directly translates to the cooling system running less frequently, which significantly lowers energy consumption and reduces wear and tear on critical mechanical components, extending the freezer's operational lifespan.

A Closer Look at Insulation Materials

Modern ULT freezers typically use a combination of materials to optimize performance, internal volume, and cost.

Polyurethane Foam: The Workhorse Insulator

This is the foundational material used in the walls, door, and cabinet of a freezer. It is a closed-cell foam that is injected between the inner and outer steel walls, where it expands and hardens.

It provides both excellent thermal resistance and structural rigidity to the unit. Modern formulations are also designed to be environmentally friendly and free of polluting substances.

Vacuum-Insulated Panels (VIPs): The High-Performance Upgrade

VIPs represent a significant leap in insulation technology. They consist of a microporous core material that is sealed inside a gas-impermeable metallic film, with all the air evacuated to create a vacuum.

Because a vacuum has virtually no molecules to conduct heat, VIPs offer an insulation value that is five to ten times higher than traditional foam for the same thickness. This allows for thinner walls, which maximizes internal storage capacity.

Understanding the Trade-offs

The choice and implementation of insulation involve balancing performance, space, and cost.

Performance vs. Cost

VIPs provide vastly superior thermal protection and temperature stability, but they are also significantly more expensive to manufacture than polyurethane foam. Freezers that rely heavily on VIPs will carry a higher initial purchase price.

Internal Volume vs. External Footprint

Because VIPs are so much thinner than foam for the same insulating power, they are key to maximizing storage space. A freezer using VIPs can offer a larger internal capacity without increasing its external footprint, a critical factor in crowded laboratory spaces.

Durability and Vulnerability

Polyurethane foam is extremely robust. VIPs, on the other hand, can be compromised. If the outer barrier of a panel is punctured, the vacuum is lost, and its insulating capability drops dramatically to that of its core material. This is why they are always protected within the freezer's steel walls.

Making the Right Choice for Your Lab

The optimal insulation strategy depends directly on your operational priorities and the value of the samples being stored.

- If your primary focus is maximum sample security: Prioritize freezers with a hybrid insulation system that combines a thick layer of foam with comprehensive VIP coverage, as this provides the best temperature stability and longest holdover time during a power outage.

- If your primary focus is maximizing storage capacity: Look for models that heavily feature Vacuum-Insulated Panels (VIPs), as their thin profile allows for the most internal storage volume within a standard external footprint.

- If your primary focus is balancing budget and performance: A freezer using high-quality, modern polyurethane foam provides a reliable and cost-effective solution that delivers excellent temperature management for a wide range of applications.

Ultimately, understanding the role of insulation empowers you to select a freezer that not only protects your valuable samples but also operates efficiently for years to come.

Summary Table:

| Insulation Material | Key Features | Primary Benefit |

|---|---|---|

| Polyurethane Foam | Closed-cell structure, rigid, cost-effective | Excellent thermal resistance and durability |

| Vacuum-Insulated Panels (VIPs) | Ultra-thin, high R-value, lightweight | Superior insulation, maximizes internal storage |

| Hybrid Systems | Combines foam and VIPs | Optimal temperature stability and energy efficiency |

Protect your most valuable samples with confidence. The right insulation is the heart of a reliable ultra-low temperature freezer. At KINTEK, we specialize in providing high-performance lab equipment, including ULT freezers designed with advanced insulation technology to ensure unmatched temperature stability, energy efficiency, and sample security. Let our experts help you select the ideal freezer for your laboratory's specific needs. Contact KINTEK today for a personalized consultation!

Visual Guide

Related Products

- 58L Precision Laboratory Ultra Low Temperature Upright Freezer for Critical Sample Storage

- 158L Precision Vertical Ultra Low Freezer for Laboratory Applications

- 408L Advanced Vertical Laboratory Ultra Low Temperature Freezer for Critical Research Material Preservation

- 308L Precision Ultra Low Temperature Freezer for Laboratory Applications

- 28L Compact Upright Ultra Low Temperature Freezer for Laboratory

People Also Ask

- How does fast temperature recovery benefit ultra-low freezers? Protect Sample Integrity and Lab Efficiency

- What is the role of an ultra-low temperature (ULT) freezer in the freeze-thaw synthesis of hydrogel nanocomposites?

- How do ultra-low temperature freezers achieve such low temperatures? The Science Behind -80°C Cooling

- What temperature ranges are typically associated with ultra-low temperature freezers? Preserve Samples from -40°C to -86°C

- What are the key features to look for in an ultra-low temperature freezer for mRNA vaccine storage? Essential Features for Absolute Vaccine Integrity