When choosing an ultra-low temperature (ULT) freezer, the decision extends far beyond the listed price and temperature range. The most critical factors to compare are those that ensure sample integrity, manage long-term operational costs, and support your lab's daily workflow. Key considerations include the cooling system's reliability, energy efficiency, and practical design features like internal configuration and alarm systems.

A ULT freezer is not a simple appliance; it is a critical piece of research infrastructure. The best choice is found not by comparing spec sheets in isolation, but by balancing the three core pillars of sample security, operational cost, and day-to-day usability.

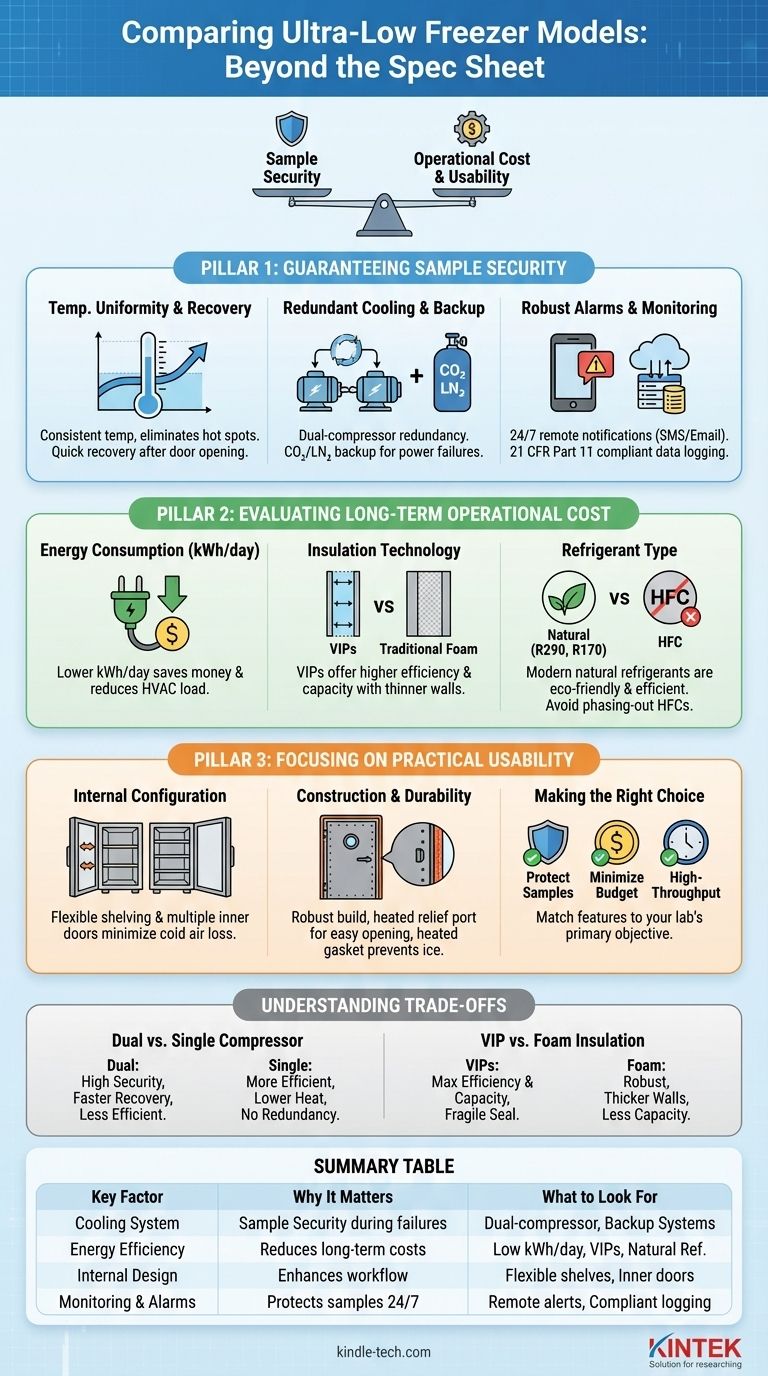

Pillar 1: Guaranteeing Sample Security

The absolute, non-negotiable function of a ULT freezer is to protect your samples. A failure here can result in the catastrophic loss of years of work.

Temperature Uniformity and Recovery

True performance is measured by temperature uniformity—the consistency of temperature throughout the entire cabinet, eliminating "hot spots" that could compromise samples.

Also, evaluate temperature recovery time. This is how quickly the freezer returns to its setpoint after a door opening, a critical metric in busy labs where frequent access is common.

Redundant Cooling and Backup Systems

Freezer compressors are mechanical systems that can fail. A dual-compressor system provides crucial redundancy; if one compressor fails, the other can typically maintain temperatures around -60°C to -70°C, preserving samples until a repair can be made.

For the highest level of security, consider models with integrated or optional CO₂ or LN₂ backup systems. These inject cryogen to maintain temperature during a power outage or complete system failure.

Robust Alarm and Monitoring Capabilities

A basic high/low temperature alarm is standard, but insufficient for valuable samples. Look for comprehensive systems that offer remote notifications via email or SMS, alerting personnel to issues 24/7.

For regulated environments, ensure the system provides detailed data logging and audit trails that are compliant with standards like 21 CFR Part 11.

Pillar 2: Evaluating Long-Term Operational Cost

A freezer's purchase price is only a fraction of its total cost of ownership. Energy consumption and maintenance are significant ongoing expenses.

Energy Consumption (kWh/day)

Manufacturers often provide an energy consumption rating, typically in kilowatt-hours per day (kWh/day). Compare these figures directly, as a more efficient unit can save thousands of dollars in electricity over its lifespan.

These savings also reduce the freezer's heat output into the room, which can lower the load on your building's HVAC system, creating a secondary cost benefit.

Insulation Technology

The type of insulation directly impacts both energy efficiency and storage capacity. Vacuum Insulated Panels (VIPs) offer a much higher insulation value than traditional foam for the same wall thickness.

This allows freezers with VIPs to have thinner walls, increasing the internal storage volume for a given external footprint.

Refrigerant Type

Modern freezers are moving toward natural refrigerants (like R290 propane or R170 ethane) due to their low environmental impact and high thermodynamic efficiency. Older units may use HFC refrigerants, which are being phased out globally.

Understanding the Trade-offs

Every design choice involves a trade-off. Understanding these compromises is key to selecting the right model for your specific needs.

Dual vs. Single Compressor Systems

A dual-compressor system offers superior sample security through redundancy and faster temperature recovery. However, it is typically less energy-efficient and has a higher initial purchase price than a single-compressor system.

A single-compressor system is more energy-efficient and often has a lower heat output. The trade-off is the lack of redundancy; a compressor failure will lead to a rapid loss of cooling.

VIP Insulation vs. Traditional Foam

VIPs provide maximum thermal efficiency and storage capacity but can be compromised if the vacuum seal is punctured during shipping or relocation. Polyurethane foam is more physically robust but requires much thicker walls, reducing internal capacity for the same footprint.

Footprint vs. Internal Capacity

Always verify the freezer's external dimensions will fit your available space, including doorways and elevators. Be aware that two freezers with the same external footprint can have different internal capacities due to variations in wall thickness and insulation type.

Pillar 3: Focusing on Practical Usability

A freezer that is difficult to use can disrupt workflow and even risk sample integrity through extended door openings.

Internal Configuration

Look for flexible shelving that can be adjusted to fit your specific boxes and racks. Multiple inner doors are essential for minimizing cold air loss when accessing a specific section of the freezer.

Construction and Durability

A robust build with heavy-gauge steel will withstand the rigors of a lab environment. Key features include a heated vacuum relief port for easy door opening and a heated door gasket to prevent ice buildup that can compromise the seal.

Making the Right Choice for Your Lab

Your final decision should be guided by your lab's primary objective.

- If your primary focus is protecting irreplaceable samples: Prioritize a dual-compressor model with integrated CO₂/LN₂ backup and comprehensive remote monitoring.

- If your primary focus is minimizing operational budget: Focus on a single-compressor model with a low kWh/day rating, VIP insulation, and natural refrigerants.

- If your primary focus is a high-throughput workflow: Emphasize fast temperature recovery times, ergonomic door handles, and an internal configuration that matches your existing inventory system.

A thorough evaluation of these pillars ensures your freezer is not just a purchase, but a lasting investment in your research.

Summary Table:

| Key Comparison Factor | Why It Matters | What to Look For |

|---|---|---|

| Cooling System | Ensures sample security during failures | Dual-compressor redundancy, backup CO₂/LN₂ systems |

| Energy Efficiency | Reduces long-term operational costs | Low kWh/day rating, VIP insulation, natural refrigerants |

| Internal Design | Enhances workflow and usability | Flexible shelving, multiple inner doors, fast temperature recovery |

| Monitoring & Alarms | Protects samples 24/7 with real-time alerts | Remote notifications (SMS/email), 21 CFR Part 11 compliant data logging |

Protect your research and optimize your lab's efficiency with the right ultra-low freezer. At KINTEK, we specialize in providing reliable lab equipment tailored to your unique needs. Our ultra-low freezers are designed with sample security, energy efficiency, and user-friendly features to support your laboratory's success. Let our experts help you find the perfect solution—contact us today to discuss your requirements!

Visual Guide

Related Products

- 108L Vertical Ultra Low Temperature ULT Freezer

- 408L Advanced Vertical Laboratory Ultra Low Temperature Freezer for Critical Research Material Preservation

- 308L Precision Ultra Low Temperature Freezer for Laboratory Applications

- 608L Essential Laboratory Ultra Low Temperature Freezer For Critical Sample Preservation

- 708L Ultra Low Temperature Freezer High Performance Laboratory Freezer

People Also Ask

- What features do ultra-low temperature freezers typically include? Ensuring Absolute Sample Security

- What temperature ranges are typically associated with ultra-low temperature freezers? Preserve Samples from -40°C to -86°C

- What is the purpose of ultra-low temperature (ULT) freezers? Preserve Critical Biological Samples

- What are the recommendations for storing mRNA vaccines in ultra-low temperature freezers? Ensure Absolute Stability at -80°C

- What are ultra-low temperature freezers designed for? Preserving Your Most Valuable Biological Samples