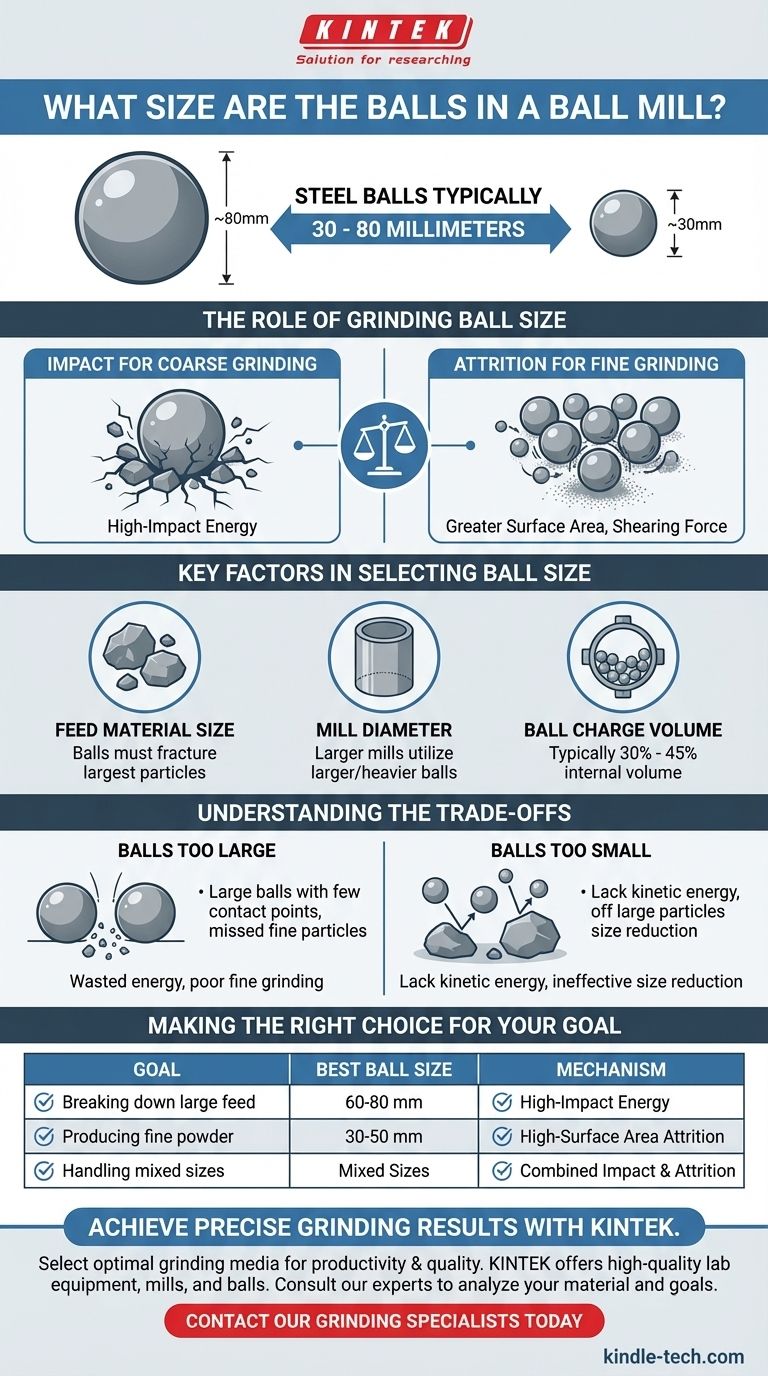

In short, the steel balls used in a ball mill typically have a diameter ranging from 30 to 80 millimeters. This size is not arbitrary; it is a critical variable selected based on the material being processed and the desired final particle size. The effectiveness of the entire grinding operation hinges on choosing the correct size of this grinding media.

The core principle is simple: Larger balls provide powerful impacts to break down large, coarse material, while smaller balls offer a greater surface area for the fine grinding and attrition needed to produce a powder. The optimal choice is always a balance between these two functions.

The Role of Grinding Ball Size

A ball mill works by tumbling grinding media (the balls) with the material to be ground. The size reduction happens through two primary mechanisms, both of which are directly dictated by the size and weight of the balls.

Impact for Coarse Grinding

Impact is the primary force responsible for breaking down large feed particles. Larger, heavier balls, when lifted by the rotation of the mill, fall with greater force.

This high-impact energy is essential for the initial stages of grinding, where you need to crack and fracture big, tough pieces of ore or other materials.

Attrition for Fine Grinding

Attrition is the grinding action that occurs from balls rubbing against each other and against the material particles. This shearing and rubbing force is what creates very fine powders.

Smaller balls are more effective at attrition because, for the same total weight, they provide a much greater number of contact points and a larger total surface area within the mill.

Key Factors in Selecting Ball Size

Choosing the right ball size isn't a guess; it's a calculated decision based on the physics of your milling operation. Several factors must be considered to achieve an efficient grind.

The Feed Material Size

The most important rule is that the grinding balls must be large and heavy enough to break the largest particles in the material you are feeding into the mill.

If the balls are too small, they will lack the necessary impact energy and will simply bounce off the larger particles, resulting in an extremely inefficient process.

The Mill Diameter

The diameter of the ball mill cylinder also plays a role. Larger diameter mills lift the balls higher before they tumble, generating more velocity and therefore more impact energy.

Because of this, larger mills can effectively utilize larger and heavier grinding balls than smaller mills.

The Ball Charge Volume

The "ball charge" refers to the total volume occupied by the balls, typically between 30% and 45% of the mill's internal volume.

This charge determines the number of impacts and the amount of attrition that occurs per revolution. It must be optimized alongside the ball size for peak efficiency.

Understanding the Trade-offs

Using the wrong size grinding media is a common and costly mistake. It leads to wasted energy, excessive wear on the equipment, and poor results.

The Problem with Balls That Are Too Large

If your grinding media is excessively large for the task, you will create powerful but infrequent impacts. This wastes energy and is ineffective for producing fine particles.

Furthermore, the limited number of contact points means the attrition process is severely hampered, making it nearly impossible to achieve a fine powder consistently.

The Downside of Balls That Are Too Small

Conversely, if the balls are too small for your feed material, they will lack the kinetic energy to fracture the larger particles.

The mill will run, consuming power, but little to no size reduction will occur. This is the most common reason for a failed or stalled grinding process.

Making the Right Choice for Your Goal

To select the correct grinding media, you must first define the primary objective of your milling process.

- If your primary focus is breaking down large, coarse feed material: You need larger balls (e.g., in the 60-80 mm range) that provide high impact energy.

- If your primary focus is producing a very fine, uniform powder: You need a charge of smaller balls (e.g., in the 30-50 mm range) to maximize surface area and attrition.

- If you are working with a mixed-size feed: An effective strategy is often to use a graded charge with a mix of ball sizes to handle both coarse impact and fine attrition in a single process.

Ultimately, matching the grinding media to the material and the desired outcome is the key to an efficient and successful milling operation.

Summary Table:

| Ball Size (Diameter) | Primary Grinding Mechanism | Best For |

|---|---|---|

| 60 - 80 mm | High-Impact Energy | Breaking down large, coarse feed material |

| 30 - 50 mm | High-Surface Area Attrition | Producing fine, uniform powders |

| Mixed Sizes | Combined Impact & Attrition | Handling a wide range of particle sizes |

Achieve precise and efficient grinding results with KINTEK.

Selecting the optimal grinding media is critical to your lab's productivity and the quality of your final product. KINTEK specializes in high-quality lab equipment and consumables, including a full range of grinding balls and mills tailored to your specific application—from coarse ore crushing to fine powder production.

Our experts can help you analyze your feed material and grinding goals to recommend the perfect media size and mill configuration, saving you time, energy, and costly trial-and-error.

Contact our grinding specialists today to optimize your milling process and unlock superior performance.

Visual Guide

Related Products

- Laboratory Single Horizontal Jar Mill

- High Energy Planetary Ball Mill Milling Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Milling Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Machine for Laboratory

- High Energy Planetary Ball Mill Milling Machine for Laboratory

People Also Ask

- What role does a high-frequency ultrasonic homogenizer play in PEO? Achieve Superior Coating Uniformity and Stability

- Why are high-power ultrasonic homogenizers essential for liquid metal nanodroplets? Overcome Surface Tension Barriers

- How does ultrasonic dispersion equipment assist in substrate pretreatment? Master Diamond Thin Film Nucleation

- What is the capacity of a colloid mill? A Guide to True Throughput vs. Rated Specs

- What is the primary function of mechanical grinding equipment in PHBV production? Optimize Feedstock for Maximum Yield

- What is the role of a laboratory-scale ball mill in the pretreatment of microalgae biomass? Boost Cell Wall Disruption

- What is the significance of using an automatic grinding and polishing machine for Boron Carbide? Achieve Mirror Finishes

- What role does the grinding process play in the synthesis of Pr3+: (Ca0.97Gd0.03)F2.03 nanopowders? Find out here!