In short, there is no single standard size for a vibrating screen. Their dimensions are defined by width and length, ranging from small, portable units around 4 feet by 8 feet (approximately 1.2m x 2.4m) to massive, stationary models exceeding 12 feet by 28 feet (approximately 3.7m x 8.5m). The "right" size is entirely dependent on the specific application's required throughput and separation efficiency.

The most critical takeaway is to stop thinking about screen size as a simple physical dimension. Instead, view it as the outcome of a careful engineering calculation designed to match a specific material, capacity, and efficiency target. The width and length are simply the results of solving for your operational goals.

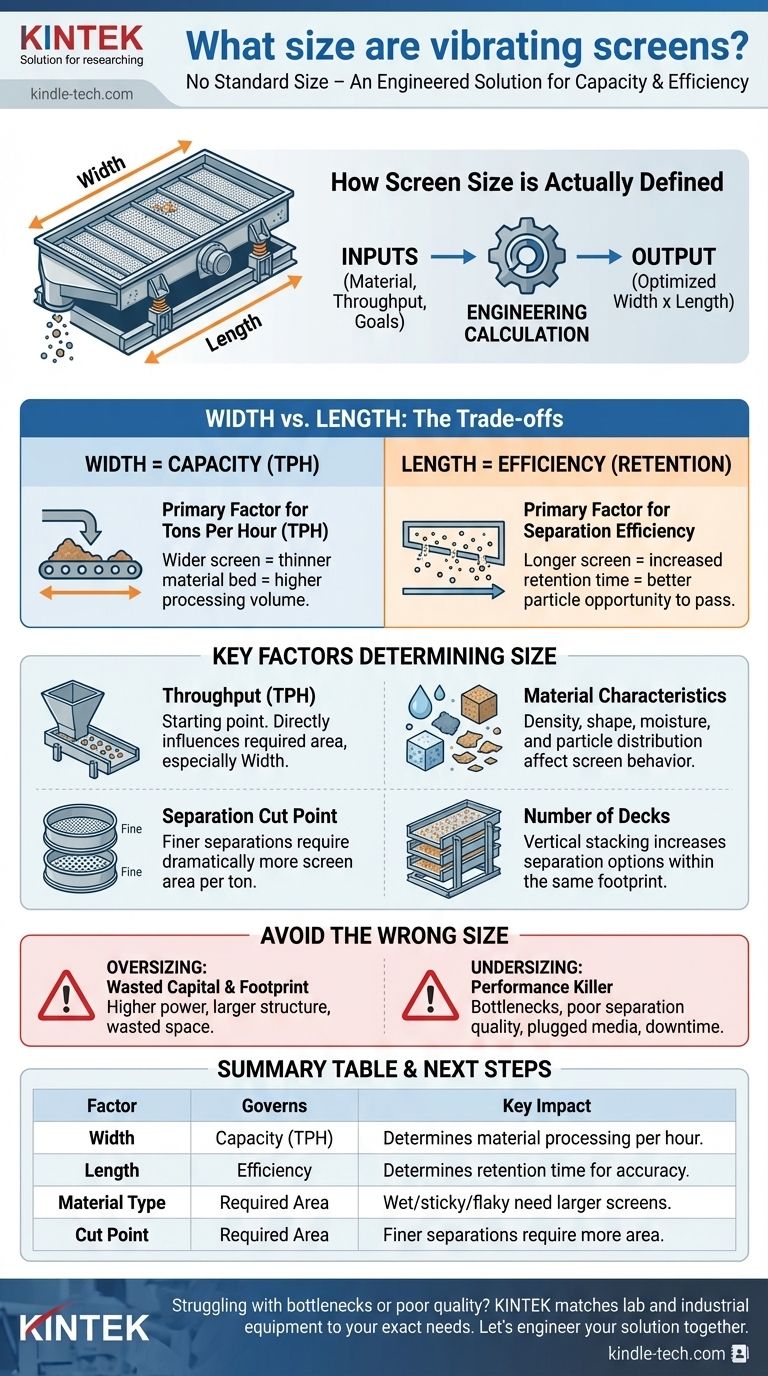

How Screen Size is Actually Defined

A vibrating screen's size is almost universally described by two numbers: its width and its length. Understanding the distinct role of each dimension is the first step toward proper selection.

Width: The Key to Capacity

The width of the screen is the primary factor that determines its capacity, or the tons per hour (TPH) it can process.

A wider screen allows the material bed to be spread more thinly as it travels across the deck. This thin bed depth is crucial because it ensures more particles come into direct contact with the screen media, giving them a better chance to pass through the openings.

Length: The Key to Efficiency

The length of the screen is the primary factor that determines separation efficiency. It dictates the material's retention time on the screen deck.

A longer screen gives each particle more opportunities to find an opening. This is especially critical for "near-size" particles—those that are only slightly smaller than the screen apertures and require more time and vibration to orient correctly and pass through.

Standard Sizing Nomenclature

You will typically see screen sizes listed in a "Width x Length" format, such as 6' x 20' (a 6-foot wide by 20-foot long screen). While imperial units (feet) are common in North America, metric dimensions are used elsewhere. The principle remains the same. For multi-deck screens, this dimension refers to the size of each individual deck.

Key Factors That Determine the Required Size

Selecting a screen is not like picking a size off a shelf. The final dimensions are calculated based on a detailed analysis of your specific operational needs.

Throughput (Tons Per Hour)

This is the starting point for any sizing calculation. The amount of material you need to process per hour directly influences the required screen area, with a heavy emphasis on width.

Material Characteristics

Not all materials behave the same. A sizing calculation must account for material density, particle shape (e.g., cubical stone vs. flat, flaky material), moisture content, and the overall particle size distribution. Wet, sticky materials are notoriously difficult to screen and will require a significantly larger screen area per ton compared to dry, free-flowing sand.

Separation Cut Point

The fineness of the separation is a major factor. Making a coarse separation, like removing +4" rock, is much easier and requires less screen area than making a fine separation at 1/8" (approx. 3mm). As the cut point gets smaller, the required screen area per ton of feed increases dramatically.

Number of Decks

A screen's footprint is its width and length, but it can have multiple decks (typically one to three) stacked vertically. A triple-deck screen allows you to make four product separations simultaneously within the same physical footprint as a single-deck machine.

Understanding the Trade-offs

Choosing the wrong size is one of the costliest mistakes in material processing. Both oversizing and undersizing have significant consequences.

Oversizing: Wasted Capital and Footprint

A screen that is too large for the job represents wasted capital expenditure. It consumes more power, requires a larger and more expensive support structure, and occupies a valuable physical footprint that could be used for other equipment.

Undersizing: The Performance Killer

This is the more common and operationally damaging error. An undersized screen will create a bottleneck for the entire operation. It leads to poor separation quality, where valuable product is carried over into the waste stream (or vice versa), and can cause screen media to become overloaded and "plugged," forcing costly shutdowns for cleaning.

The Width vs. Length Dilemma

For high-tonnage "scalping" applications where the goal is simply to remove oversized boulders, width is the most important factor to handle the volume. For fine-sizing applications where accuracy is paramount, ensuring sufficient length for retention time is critical to achieving the desired product quality.

How to Select the Correct Screen Size

Your goal is not to "pick a size" but to provide the right information to determine the correct size for your process.

- If your primary focus is maximizing throughput: Prioritize screen width and work with a manufacturer to ensure the drive system and screen media can handle the high tonnage without blinding.

- If your primary focus is achieving high separation efficiency: Ensure the screen has sufficient length to provide the necessary retention time for your specific material and cut point.

- If you are dealing with difficult materials (wet, sticky, or flaky): Be conservative with standard sizing calculations and consult an expert, as you will likely need a larger screen or a specialized high-energy model.

- If you are starting a new project: The most crucial step is to gather accurate data on your feed material and operational goals. Provide a potential supplier with the material type, TPH, feed gradation, and desired products to allow for a proper engineering analysis.

Ultimately, proper screen sizing is a calculated engineering decision that balances capacity and efficiency to meet your specific production targets.

Summary Table:

| Factor | Governs | Key Impact |

|---|---|---|

| Width | Capacity (TPH) | Determines how much material can be processed per hour. |

| Length | Efficiency | Determines retention time for accurate particle separation. |

| Material Type | Required Screen Area | Wet, sticky, or flaky materials need larger screens. |

| Cut Point | Required Screen Area | Finer separations require significantly more screen area. |

Struggling with capacity bottlenecks or poor product quality? The right vibrating screen is an engineered solution, not just a physical dimension. At KINTEK, we specialize in matching lab and industrial equipment to your exact operational needs. Our experts will analyze your material, throughput, and efficiency goals to recommend the ideal screen size and configuration.

Let's engineer your solution together. Contact our screening specialists today for a personalized consultation.

Visual Guide

Related Products

- Three-dimensional electromagnetic sieving instrument

- Laboratory Test Sieves and Vibratory Sieve Shaker Machine

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Laboratory Vibratory Sieve Shaker Machine for Dry and Wet Three-Dimensional Sieving

- Laboratory Wet Three-Dimensional Vibratory Sieve Shaker Machine

People Also Ask

- What are the different types of sieving machines? Choose the Right Motion for Your Material

- What are the disadvantages of sieve machine? Key Limitations in Particle Size Analysis

- What are the applications of sieving machine? From Mining to Pharmaceuticals

- What is the principle of sieving machine? Achieve Accurate Particle Size Separation

- What is the use of vibrating sieve machine? Achieve Precise Particle Size Analysis for Your Lab