In short, a hammer mill excels at grinding dry, brittle, and low-fat materials. It is the ideal tool for processing samples like grains, cereals, most spices, and dried beans, where the goal is to rapidly reduce them to a uniform, fine powder. Its effectiveness hinges on the material's ability to shatter upon high-speed impact.

The suitability of a food sample for a hammer mill is determined not by its category (e.g., "fruit" or "grain") but by its physical properties. The critical factors are low moisture, low oil content, and a brittle structure that shatters rather than smears or deforms.

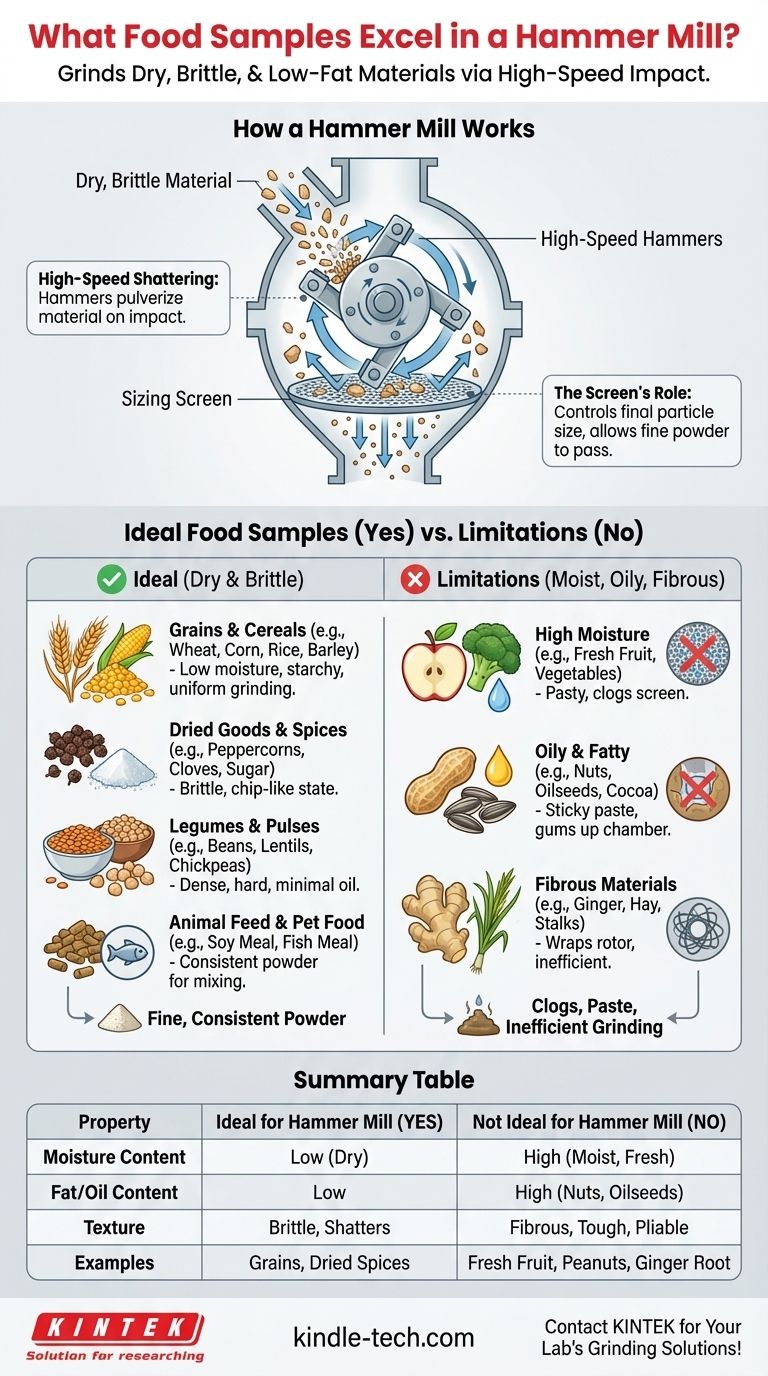

How a Hammer Mill Works: The Principle of Impact

To understand which foods work well, you must first understand the mechanism. A hammer mill doesn't cut or shear; it pulverizes.

High-Speed Shattering

Inside the grinding chamber, a central rotor spins at thousands of RPM. Attached to this rotor are multiple swinging or fixed "hammers." As the material enters the chamber, these hammers strike it with tremendous force, causing it to shatter.

The Role of the Screen

The grinding chamber is lined with a perforated metal screen. Material remains in the chamber, continuously struck by the hammers, until its particles are small enough to pass through the holes in this screen. The size of these holes dictates the final particle size of the ground sample.

Why Brittle Materials Excel

This impact-based method is highly efficient for brittle materials. Think of shattering glass with a hammer—it's an instant and complete breakdown. Dry grains, crystalline sugar, or hard-baked goods behave similarly, breaking cleanly along their internal structures.

Ideal Food Samples for Hammer Milling

Based on the principle of impact, the following categories of food samples are excellent candidates for hammer milling.

Grains and Cereals

This is the most common application. Wheat, corn, rice, barley, oats, and sorghum are all ideal. Their low moisture content and starchy, brittle structure allow for fast and uniform grinding.

Dried Goods and Spices

Most dried spices, such as peppercorns, cloves, and coriander seeds, grind exceptionally well. Dehydrated vegetables and fruits can also be processed, provided they are dried to a very brittle, chip-like state. Crystalline materials like sugar are also ground effortlessly.

Legumes and Pulses

Dried beans, chickpeas, lentils, and peas are easily pulverized in a hammer mill. They are dense, hard, and contain minimal oil, making them perfect for this type of size reduction.

Animal Feed and Pet Food Components

Hammer mills are a cornerstone of the feed industry. They are used to grind components like soy meal, fish meal, and bone meal into a consistent powder for mixing and pelletizing.

Understanding the Limitations and Trade-offs

A hammer mill is not a universal solution. Attempting to grind unsuitable materials leads to poor results, equipment damage, and sample degradation.

The Problem with High Moisture Content

Moist samples do not shatter. Instead, they deform, smear, and turn into a paste. This pasty material will not break down efficiently and will quickly clog the holes of the screen, halting the process entirely. Grinding fresh fruit or vegetables is not feasible.

The Challenge of Oily and Fatty Samples

High-fat samples like nuts (almonds, peanuts), oilseeds (flax, sunflower), and cocoa beans present a major challenge. The pressure and friction from milling release oils, creating a sticky, oily paste that clogs the screen and gums up the grinding chamber.

The Issue with Fibrous Materials

Tough, fibrous materials like ginger root, hay, or some plant husks do not shatter well. The fibers tend to get pulled and torn rather than breaking, and they can wrap around the rotor, leading to clogs and inefficient grinding. A cutting or knife mill is better suited for these materials.

Heat Generation

The high speed of the rotor generates significant heat. This can be a problem for heat-sensitive samples, potentially degrading vitamins, altering flavors, or denaturing proteins. For these applications, cryogenic grinding (using liquid nitrogen) or a different mill type may be necessary.

Making the Right Choice for Your Sample

To determine if a hammer mill is right for you, evaluate your material's core properties.

- If your primary sample is dry, brittle, and low in oil (like corn, wheat, or dried beans): A hammer mill is one of the most efficient and effective tools you can choose for rapid size reduction.

- If your primary sample has high moisture or fat content (like fresh produce, nuts, or oilseeds): You must consider a different method, such as a knife mill, or pre-process the sample through freeze-drying to make it brittle.

- If your primary sample is tough and fibrous (like plant stalks or tough roots): A cutting mill, which uses sharp blades to shear the material, will provide far superior results.

Ultimately, selecting the right grinding tool requires matching the mill's mechanical action to the physical properties of your sample.

Summary Table:

| Property | Ideal for Hammer Mill | Not Ideal for Hammer Mill |

|---|---|---|

| Moisture Content | Low (Dry) | High (Moist, Fresh) |

| Fat/Oil Content | Low | High (Nuts, Oilseeds) |

| Texture/Structure | Brittle, Shatters | Fibrous, Tough, Pliable |

| Example Materials | Grains, Dried Spices, Legumes | Fresh Fruit, Peanuts, Ginger Root |

Need to grind dry, brittle food samples efficiently? KINTEK specializes in laboratory equipment, including hammer mills designed for optimal particle size reduction of grains, spices, and dried goods. Our experts can help you select the right mill for your specific application to ensure consistent, high-quality results. Contact our team today to discuss your lab's grinding needs and find the perfect solution!

Visual Guide

Related Products

- Laboratory Sealed Hammer Crusher for Efficient Sample Preparation

- Laboratory Grinding Mill Mortar Grinder for Sample Preparation

- Laboratory Ball Mill Jar Mill with Metal Alloy Grinding Jar and Balls

- Laboratory Single Horizontal Jar Mill

- Laboratory Four-Body Horizontal Jar Mill

People Also Ask

- What is the laboratory apparatus used for grinding? Find the Perfect Mill for Your Sample

- What is the grinding media in ball mills? Choose the Right Media for Optimal Grinding & Purity

- What role does mechanochemical grinding play in the raw material preparation of lithium-based ceramics? Boost Efficiency

- What is the primary function of a ball mill in calcium thermal reduction? Optimize Your Raw Material Preparation

- What are the advantages of using 1mm zirconia milling balls? Optimize SnO2 and Li2SnO3 Anode Synthesis

- How does a high-energy ball mill contribute to L*LS synthesis? Engineering Advanced Composite Cathode Materials

- What is the impact of speed on ball mill performance? Optimize Grinding Efficiency & Particle Size

- What are 5 uses of hammer mill? Unlock Versatile Size Reduction for Your Industry