At its core, sieving is a precise method of particle size separation. This process involves agitating a powder on a screen or mesh, which allows particles smaller than the mesh openings to pass through while retaining larger particles on the surface. This fundamental technique is not just for cleaning; it is a critical step for controlling the properties of both the powder and the final product you intend to create.

The primary reason for sieving powder is to achieve a specific and controlled particle size distribution. This control is essential because the size and arrangement of particles directly dictate the powder's behavior during processing and determine the final material's density, strength, and overall uniformity.

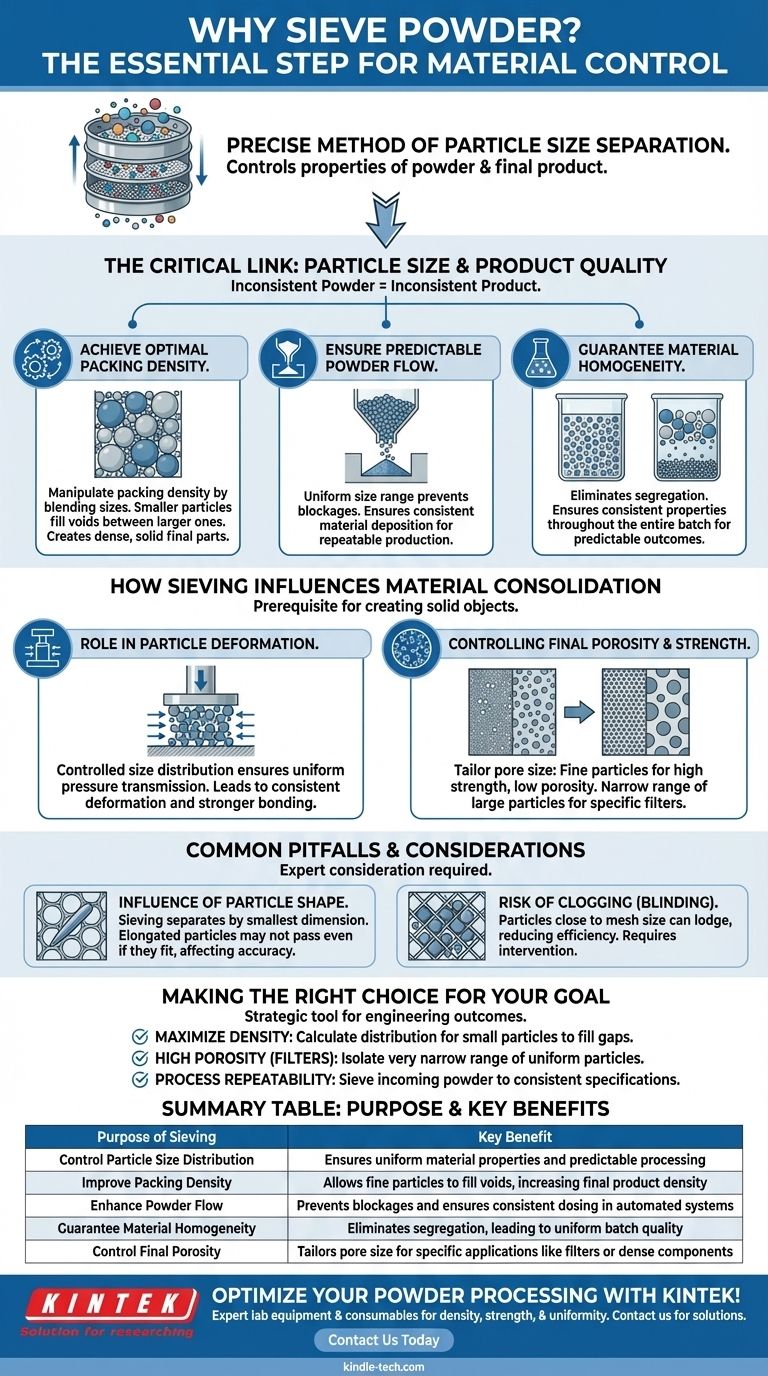

The Critical Link Between Particle Size and Product Quality

Controlling particle size is fundamental to materials science and manufacturing. An inconsistent powder leads to an inconsistent product. Sieving is the primary tool for establishing this crucial consistency from the very beginning.

Achieving Optimal Packing Density

The way powder particles fit together is known as packing density. Sieving allows you to manipulate this property with precision.

By separating sizes, you can create a specific blend where smaller particles fill the voids, or gaps, between larger ones. This process, as noted in pressing, forces grains into "closer contact" and a "closer packing," which is essential for creating a dense, solid final part.

Ensuring Predictable Powder Flow

For any automated manufacturing process, from pharmaceuticals to metallurgy, the powder must flow consistently from a hopper into a die or mold.

The size and shape of particles heavily influence this flowability. Sieving to achieve a uniform size range prevents blockages and ensures that the same amount of material is deposited each time, leading to repeatable and reliable production.

Guaranteeing Material Homogeneity

Without sieving, a batch of powder can have significant variations, with finer particles settling at the bottom and larger ones on top.

This segregation leads to non-uniform products. Sieving ensures that the powder you start with is homogeneous, meaning its properties are consistent throughout the batch. This is the foundation for a predictable outcome.

How Sieving Influences Material Consolidation

The reference to "pressing powder samples" highlights a common application: creating a solid object from loose powder. Sieving is a prerequisite for success in this process.

The Role in Particle Deformation

When pressure is applied to a powder, the particles are forced together, deforming elastically and plastically to bond.

A controlled particle size distribution ensures that pressure is transmitted more uniformly throughout the powder mass. This leads to more consistent deformation and stronger, more reliable bonding between particles.

Controlling Final Porosity and Strength

The spaces between particles become the pores in the final product. The size of these pores is directly related to the size of the starting particles.

To create a high-strength, low-porosity material, you would typically use a distribution of fine particles. Conversely, to create a specific type of filter, you might sieve for a narrow range of larger particles to produce consistent, open pores.

Common Pitfalls and Considerations

While essential, sieving is a physical process with practical limitations that require an expert's consideration.

The Influence of Particle Shape

Sieving separates based on a particle's smallest dimension. An elongated or needle-shaped particle may fail to pass through a mesh opening that it could theoretically fit through if oriented differently. This can affect the accuracy of the size separation.

The Risk of Clogging (Blinding)

During the process, particles that are very close to the size of the mesh openings can become lodged, blocking the screen. This phenomenon, known as "blinding," reduces the efficiency of the sieve and requires intervention to correct.

It's a Single-Variable Control

Sieving provides excellent control over particle size, but it is only one piece of the puzzle. Other critical factors like particle shape, surface chemistry, and moisture content also heavily influence the powder's behavior and the final product's properties.

Making the Right Choice for Your Goal

Sieving is not a one-size-fits-all step; it is a tool to be used strategically to achieve a specific engineering outcome.

- If your primary focus is maximizing final density: Sieve to create a calculated distribution of particle sizes, allowing smaller particles to efficiently fill the gaps between larger ones.

- If your primary focus is high porosity (e.g., for filters): Sieve to isolate a very narrow range of uniformly sized particles to create predictable and consistent voids.

- If your primary focus is process repeatability: Sieve all incoming raw powder to a consistent, documented specification to ensure every batch behaves identically in your manufacturing line.

Ultimately, sieving transforms a raw, variable powder into a predictable and engineered material component.

Summary Table:

| Purpose of Sieving | Key Benefit |

|---|---|

| Control Particle Size Distribution | Ensures uniform material properties and predictable processing |

| Improve Packing Density | Allows fine particles to fill voids, increasing final product density |

| Enhance Powder Flow | Prevents blockages and ensures consistent dosing in automated systems |

| Guarantee Material Homogeneity | Eliminates segregation, leading to uniform batch quality |

| Control Final Porosity | Tailors pore size for specific applications like filters or dense components |

Optimize your powder processing with precision sieving solutions from KINTEK! Whether you're in pharmaceuticals, metallurgy, or materials science, achieving consistent particle size is critical for product quality and manufacturing efficiency. Our expert team provides reliable lab equipment and consumables tailored to your specific needs—ensuring you get the density, strength, and uniformity your applications demand. Contact us today to discuss how we can support your laboratory's success!

Visual Guide

Related Products

- Laboratory Test Sieves and Vibratory Sieve Shaker Machine

- Three-dimensional electromagnetic sieving instrument

- Laboratory Vibratory Sieve Shaker Machine for Dry and Wet Three-Dimensional Sieving

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Laboratory Multifunctional Small Speed-Adjustable Horizontal Mechanical Shaker for Lab

People Also Ask

- What are the disadvantages of sieve machine? Key Limitations in Particle Size Analysis

- What function does a sieving system perform during HPS powder pretreatment? Ensure Uniform Particle Size Distribution

- Why is a precision vibratory sieving system important for Pt/Pd alloy analysis? Ensure Data Integrity & XRD Accuracy

- What is the significance of using a fine sieving system for catalyst particles? Optimize Size for Maximum Reactivity

- Why is powder classification using standard sieves essential for SHS reactions? Unlock Superior Nitriding Results