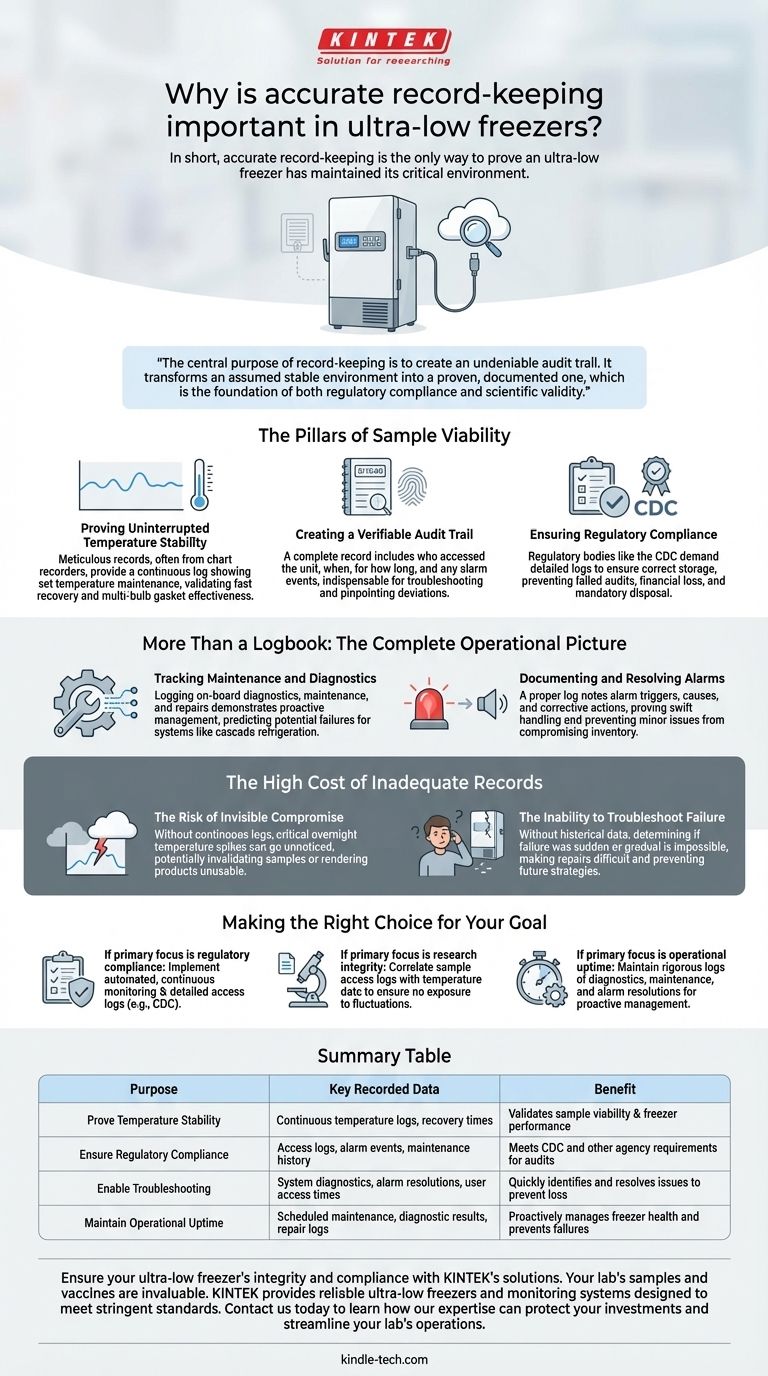

In short, accurate record-keeping is the only way to prove an ultra-low freezer has maintained its critical environment. This documentation is essential for protecting valuable temperature-sensitive products, ensuring compliance with strict regulatory guidelines like the CDC's Vaccine Storage and Handling Toolkit, and guaranteeing the scientific integrity of the items stored inside.

The central purpose of record-keeping is to create an undeniable audit trail. It transforms an assumed stable environment into a proven, documented one, which is the foundation of both regulatory compliance and scientific validity.

The Pillars of Sample Viability

Accurate records provide the objective evidence needed to trust the materials stored within an ultra-low freezer. Without this history, the viability of every sample is questionable.

Proving Uninterrupted Temperature Stability

The most fundamental job of an ultra-low freezer is to stay cold. Meticulous records, often gathered by a temperature chart recorder, provide a continuous log of the internal temperature.

This data proves that the set temperature was maintained, even during door openings. It validates the effectiveness of features like fast temperature recovery and multi-bulb gaskets, which are designed to minimize fluctuations.

Creating a Verifiable Audit Trail

A complete record goes beyond temperature. It includes a history of who accessed the unit, when, and for how long, as well as any alarm events.

This trail is indispensable for troubleshooting. If a sample is ever compromised, the records can help pinpoint exactly when the deviation occurred, turning a mystery into a solvable problem.

Ensuring Regulatory Compliance

For many labs and clinics, record-keeping is not optional. Regulatory bodies like the CDC demand detailed logs to ensure that products like vaccines have been stored correctly throughout their lifecycle.

Failure to provide these records can result in failed audits, significant financial loss, and the mandatory disposal of valuable inventory.

More Than a Logbook: The Complete Operational Picture

Effective record-keeping integrates data from all of the freezer's systems to provide a holistic view of its health and performance.

Tracking Maintenance and Diagnostics

Modern ultra-low freezers often feature on-board system diagnostics. Logging the results of these checks, along with all scheduled maintenance and repairs, demonstrates proactive management.

This history helps predict potential failures and ensures the unit—from its cascade refrigeration system to its gaskets—is always performing optimally.

Documenting and Resolving Alarms

Every visual and audible alarm is a critical data point. A proper log will note when an alarm was triggered, its cause, and the corrective action taken.

This documentation proves that deviations were handled swiftly and correctly, preventing minor issues from compromising the entire inventory.

The High Cost of Inadequate Records

Neglecting documentation introduces unacceptable risks that can undermine an entire operation. The primary trade-off is sacrificing certainty for convenience, which is a dangerous gamble.

The Risk of Invisible Compromise

Without a continuous temperature log, a brief but critical temperature spike overnight could go completely unnoticed.

This leaves you in a position where you cannot guarantee the integrity of your samples, potentially invalidating research or rendering therapeutic products unusable.

The Inability to Troubleshoot Failure

When a freezer fails, the first question is always "when did the problem start?" Without historical data from system diagnostics and temperature logs, it is nearly impossible to determine if the failure was a sudden event or a gradual decline.

This lack of information makes repairs more difficult and prevents you from implementing strategies to avoid future failures.

Making the Right Choice for Your Goal

Implementing a robust record-keeping strategy is about defining your priorities and choosing the right tools to meet them.

- If your primary focus is regulatory compliance: You must implement automated, continuous temperature monitoring and detailed access logs that meet or exceed specific agency requirements (e.g., CDC).

- If your primary focus is research integrity: Correlate sample access logs with temperature data to ensure no sample was exposed to temperature fluctuations during handling.

- If your primary focus is operational uptime: Maintain rigorous logs of all system diagnostic checks, maintenance activities, and alarm resolutions to proactively manage freezer health.

Ultimately, meticulous record-keeping transforms your freezer from a passive storage container into a fully managed, validated, and trustworthy scientific instrument.

Summary Table:

| Purpose | Key Recorded Data | Benefit |

|---|---|---|

| Prove Temperature Stability | Continuous temperature logs, recovery times | Validates sample viability and freezer performance |

| Ensure Regulatory Compliance | Access logs, alarm events, maintenance history | Meets CDC and other agency requirements for audits |

| Enable Troubleshooting | System diagnostics, alarm resolutions, user access times | Quickly identifies and resolves issues to prevent loss |

| Maintain Operational Uptime | Scheduled maintenance, diagnostic results, repair logs | Proactively manages freezer health and prevents failures |

Ensure your ultra-low freezer's integrity and compliance with KINTEK's solutions.

Your lab's samples and vaccines are invaluable—don't leave their safety to chance. KINTEK specializes in lab equipment and consumables, providing reliable ultra-low freezers and monitoring systems designed to meet stringent regulatory standards. We help you maintain precise temperature control, detailed audit trails, and seamless compliance, so you can focus on your critical work.

Contact us today to learn how our equipment and expertise can protect your investments and streamline your lab's operations.

Visual Guide

Related Products

- 58L Precision Laboratory Ultra Low Temperature Upright Freezer for Critical Sample Storage

- 408L Advanced Vertical Laboratory Ultra Low Temperature Freezer for Critical Research Material Preservation

- 108L Vertical Ultra Low Temperature ULT Freezer

- 508L Advanced Vertical Ultra Low Temperature Freezer for Critical Laboratory Storage

- 208L Advanced Precision Laboratory Ultra Low Temperature Freezer for Cold Storage

People Also Ask

- What is the temperature control capability of ultra-low freezers? Precise Stability Down to -86°C

- What are the recommendations for storing mRNA vaccines in ultra-low temperature freezers? Ensure Absolute Stability at -80°C

- What are the key features to look for in an ultra-low temperature freezer for mRNA vaccine storage? Essential Features for Absolute Vaccine Integrity

- How do ultra-low temperature freezers work? Unlocking the Secrets of -86°C Sample Preservation

- What features do ultra-low temperature freezers typically include? Ensuring Absolute Sample Security