In material analysis, accuracy is non-negotiable. Crushing and grinding, a process known as comminution, is the critical first step to transform a large, non-uniform (heterogeneous) material into a fine, uniform (homogeneous) powder. This ensures that the small portion taken for testing is a true representation of the entire original sample, which is the only way to generate reliable and repeatable data.

The primary goal of crushing and grinding is not simply to make a sample smaller. It is to overcome the fundamental problem of heterogeneity, ensuring that any sub-sample you test has the same composition as the bulk material it came from. Without this step, your analytical results would be a matter of chance.

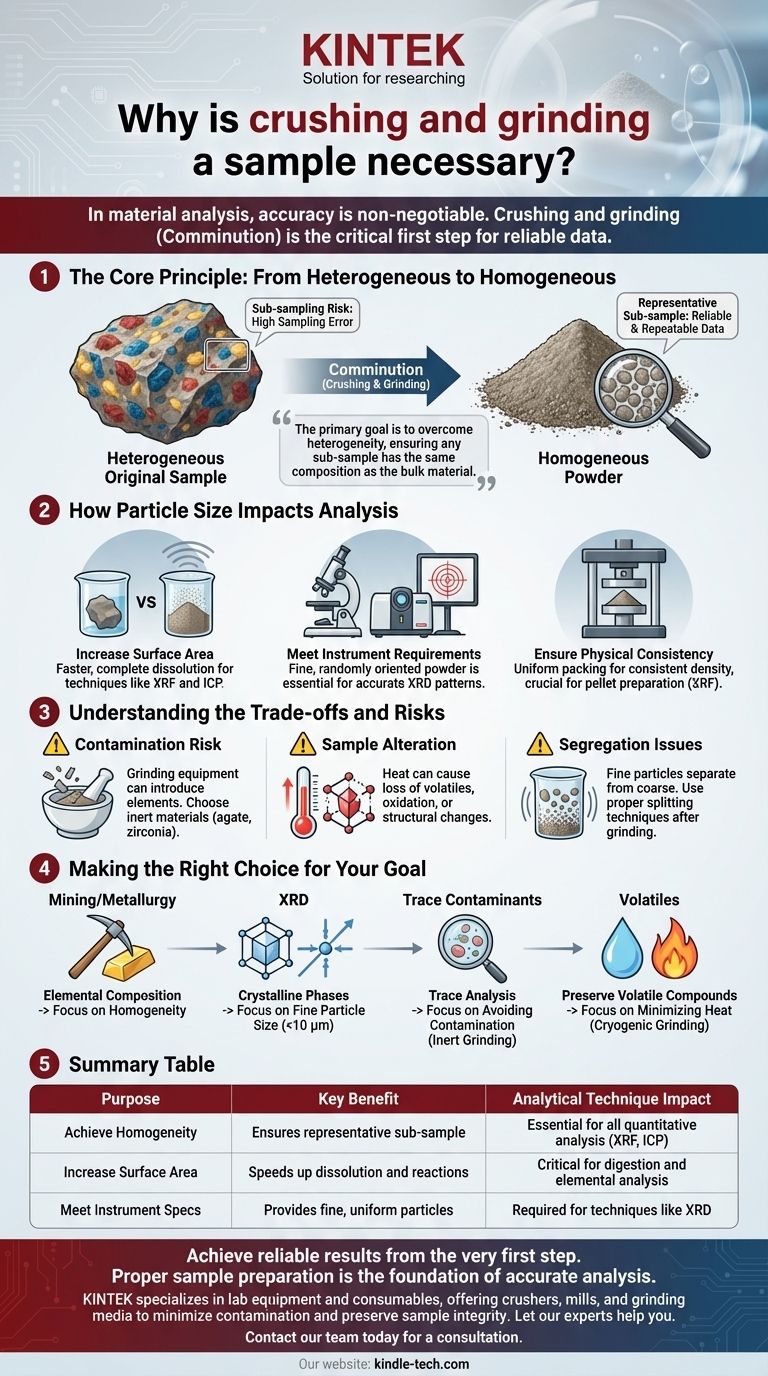

The Core Principle: From Heterogeneous to Homogeneous

The entire purpose of sample preparation is to create a small amount of material that is chemically and physically identical to a much larger source. Comminution is the mechanical process that makes this possible.

The Problem of the Original Sample

Most raw materials—be it a mineral ore, a soil sample, or a pharmaceutical batch—are heterogeneous. This means their constituent parts are unevenly distributed.

Imagine a piece of granite. It contains distinct crystals of quartz, feldspar, and mica. If you break off one small chip, you might get a piece that is mostly quartz. Another chip might be all feldspar. Neither chip accurately represents the overall composition of the granite block.

The Challenge of Sub-sampling

You cannot analyze an entire truckload of ore or a full batch of concrete. You must take a tiny sub-sample—often just a few grams or less—for laboratory analysis.

If you take a sub-sample from a heterogeneous source, your results are subject to a sampling error. The composition of your sub-sample will depend entirely on where you grabbed it from, making the analysis unreliable and not representative of the whole.

Achieving Homogeneity

Crushing and grinding solves this problem by reducing the particle size to a point where the individual components are thoroughly mixed.

Think of it like making a soup. A chunky vegetable soup is heterogeneous; one spoonful might have a carrot and a potato, while the next has only broth. By blending that soup into a smooth puree, you create a homogeneous mixture. Now, every single spoonful has the exact same flavor and nutritional content. This is what grinding does for a solid sample.

How Particle Size Impacts Analysis

Beyond creating a representative sample, reducing particle size is often a technical prerequisite for the analytical instruments themselves.

Increasing Reactive Surface Area

Chemical reactions, including dissolution for analysis, occur on the surface of a particle. By grinding a sample into a fine powder, you dramatically increase its total surface area.

This allows acids or other reagents to digest the sample much faster and more completely. For techniques like X-ray Fluorescence (XRF) or Inductively Coupled Plasma (ICP) analysis, complete dissolution is essential for accuracy.

Meeting Instrument Requirements

Many analytical instruments have strict requirements for sample particle size.

For example, X-ray Diffraction (XRD), used to identify crystalline structures, requires a fine, randomly oriented powder to produce a clean and accurate diffraction pattern. Large particles can lead to "spotty" patterns and incorrect phase identification.

Ensuring Physical Consistency

Fine powders tend to pack more uniformly and predictably than coarse, irregular particles. This is important for techniques where sample density can affect the result, such as when pressing pellets for XRF analysis.

Understanding the Trade-offs and Risks

While necessary, comminution is not without its pitfalls. An effective process minimizes these risks.

The Risk of Contamination

The grinding equipment itself can contaminate your sample. A steel grinding bowl can introduce iron, chromium, and nickel, which is a disaster if you are trying to measure those elements at trace levels.

Choosing the right grinding material (e.g., agate, zirconia, tungsten carbide) is critical to avoid adding elements that would interfere with your analysis.

The Danger of Altering the Sample

The energy from grinding generates heat. This heat can alter the sample in undesirable ways.

It can cause a loss of volatile components (like water), induce oxidation, or even change the crystalline structure of the material. This is a significant risk, as you might inadvertently change the very property you intend to measure.

Creating Segregation Issues

Ironically, grinding can sometimes lead to segregation. Very fine particles can separate from coarser ones due to vibration, a process similar to how shaking a can of mixed nuts causes the largest nuts to rise to the top.

Proper sample splitting techniques, such as using a rotary splitter after grinding, are essential to ensure the final sub-sample is still representative.

Making the Right Choice for Your Goal

The right approach to crushing and grinding depends entirely on your analytical objective.

- If your primary focus is elemental composition (like in mining or metallurgy): Your absolute priority is achieving homogeneity to ensure the analysis reflects the true economic value of the bulk material.

- If your primary focus is identifying crystalline phases (with XRD): Achieving a specific, fine particle size (typically <10 microns) is critical for obtaining a clean diffraction pattern without bias from large crystals.

- If your primary focus is analyzing for trace contaminants: Your main concern is avoiding contamination from the grinding equipment itself; choosing an inert material like agate is paramount.

- If your primary focus is preserving volatile compounds (like moisture content): You must minimize grinding energy and time to avoid heat-induced changes, sometimes requiring specialized techniques like cryogenic (freeze) grinding.

Ultimately, proper sample preparation is the foundation upon which all reliable analytical data is built.

Summary Table:

| Purpose | Key Benefit | Analytical Technique Impact |

|---|---|---|

| Achieve Homogeneity | Ensures sub-sample represents the entire bulk material | Essential for all quantitative analysis (e.g., XRF, ICP) |

| Increase Surface Area | Speeds up dissolution and chemical reactions | Critical for digestion and elemental analysis |

| Meet Instrument Specs | Provides fine, uniform particles for accurate readings | Required for techniques like XRD |

Achieve reliable results from the very first step. Proper sample preparation is the foundation of accurate analysis. KINTEK specializes in lab equipment and consumables, offering a range of crushers, mills, and grinding media designed to minimize contamination and preserve sample integrity. Let our experts help you select the right equipment for your specific material and analytical goals. Contact our team today for a consultation and ensure your data is built on a solid foundation.

Visual Guide

Related Products

- Laboratory Ball Mill Jar Mill with Metal Alloy Grinding Jar and Balls

- Laboratory Sealed Hammer Crusher for Efficient Sample Preparation

- Laboratory Grinding Mill Mortar Grinder for Sample Preparation

- Laboratory Four-Body Horizontal Jar Mill

- Stainless Steel Laboratory Ball Mill for Dry Powder and Liquid with Ceramic Polyurethane Lining

People Also Ask

- What is the preventive maintenance of ball mill? Ensure Maximum Uptime and Reliability

- What is the purpose of ball milling? A Versatile Tool for Material Synthesis and Modification

- What are the factors affecting grinding efficiency? Optimize Your Process for Maximum Output

- What is the primary function of the grinding process in LiCoO2/LSPS mixtures? Optimize Solid-State Battery Conductivity

- What is the average speed of a ball mill? Optimize Grinding with Critical Speed Calculations