The primary benefit of using a wet mill is to produce coffee with a cleaner, brighter, and more consistent flavor profile. This method, formally known as the washed process, meticulously removes the fruit surrounding the coffee bean before drying. This allows the bean's intrinsic characteristics—its origin, variety, and terroir—to define the final taste in the cup.

The choice between wet milling (washed process) and dry milling (natural process) is not a matter of one being superior. It is a deliberate decision to target a specific flavor profile: wet milling aims for clarity and precision, while dry milling cultivates fruit-forward complexity and body.

Clarifying the Terminology: Wet vs. Dry Processing

Before diving deeper, it's critical to understand what these terms mean in the context of coffee production. The user's question touches on a common point of confusion.

The Two Meanings of "Dry Mill"

The term "dry mill" can refer to two very different things. First, it can describe the natural process, where the entire coffee cherry is dried whole. This is the direct counterpart to the wet process.

However, "dry mill" also refers to the final stage of preparation for all coffees, where the dried beans have their final protective layers (parchment or husk) removed and are then sorted and graded before export. For clarity, this article will use "wet mill" to mean the washed process and "dry mill" to mean the natural process.

The Core Goal of Wet Milling: Precision and Purity

The washed process is a method of control. By removing all external variables from the fruit, producers can present a coffee in its purest form.

How the Washed Process Works

The process involves several key steps. First, the coffee cherry's outer skin and pulp are mechanically removed in a machine called a depulper.

The bean is then left with a sticky layer of mucilage. This layer is broken down and removed, typically through controlled fermentation in water tanks or by using high-pressure mechanical scrubbers.

Finally, the clean beans are thoroughly washed before being laid out to dry. This entire sequence happens within hours of the coffee being picked.

The Impact on Flavor

By removing the fruit early, the fermentation of fruit sugars does not impart flavor to the bean. The resulting coffee has a "clean" taste profile, allowing the subtle notes of its origin to shine through.

This method typically produces coffees with higher acidity, a lighter body, and bright, often floral or citrusy, tasting notes. It highlights the work done on the farm level—from soil health to the specific coffee plant variety.

Consistency as a Key Advantage

The washed process offers producers a high degree of control over the outcome. Timed fermentation and mechanical scrubbing reduce the risk of mold, over-fermentation, and other defects that can ruin a batch.

This leads to a more uniform and predictable product, which is highly valued by specialty coffee roasters and consumers seeking a consistent experience.

The Alternative Approach: Dry Milling (Natural Process)

The natural process is the oldest method of processing coffee. Instead of removing the fruit, it uses the whole cherry to shape the final flavor.

How the Natural Process Works

In this method, the freshly picked coffee cherries are laid out to dry in the sun on raised beds or patios, with the entire fruit still intact.

They are raked and turned frequently to ensure even drying and prevent mold. This process can take several weeks, during which the sugars and flavors from the drying fruit pulp are absorbed by the bean inside.

The Impact on Flavor

This absorption of fruit sugars creates a dramatically different flavor profile. Natural process coffees are known for their heavy body, low acidity, and intense, fruit-forward flavors.

Common tasting notes include strawberry, blueberry, and tropical fruits, often accompanied by a winey or even fermented quality. This method is celebrated for the unique and complex cup profiles it can produce.

Understanding the Trade-offs

Neither method is perfect; each comes with a distinct set of advantages and disadvantages that producers must weigh.

Water Usage: The Environmental Consideration

The most significant trade-off of the wet mill (washed) process is its high water consumption. In coffee-growing regions where water is a scarce resource, this poses a serious environmental and economic challenge.

The natural process, by contrast, requires almost no water, making it a far more sustainable choice in dry climates.

Flavor Profile: Clarity vs. Complexity

The choice is fundamentally about the desired outcome. The wet process is for producers who want to showcase the pure, unadulterated flavor of their coffee beans.

The dry process is for those who want to create a complex, fruit-driven flavor profile, where the processing itself becomes a signature part of the final taste.

Defect Risk and Skill

While the washed process is more controlled, the natural process is far riskier. Uneven drying can easily lead to mold or sour, over-fermented flavors.

Producing a high-quality, clean natural coffee requires immense skill, ideal weather conditions, and meticulous attention to detail, making it a more challenging and less consistent method.

Making the Right Choice for Your Goal

Ultimately, the decision to use a wet or dry mill is driven by the desired result, available resources, and local climate.

- If your primary focus is a consistent, bright, and clean flavor profile: The wet mill (washed process) is the definitive choice, as it minimizes fruit influence and highlights the coffee's origin.

- If your primary focus is a complex, fruit-forward, and heavy-bodied cup: The dry mill (natural process) is the method that will deliver those unique, fermented characteristics.

- If your primary focus is environmental sustainability in a water-scarce region: The dry process is often the more responsible and practical choice.

Understanding these fundamental processing methods empowers you to select coffees with intention, aligning the final cup with your desired taste.

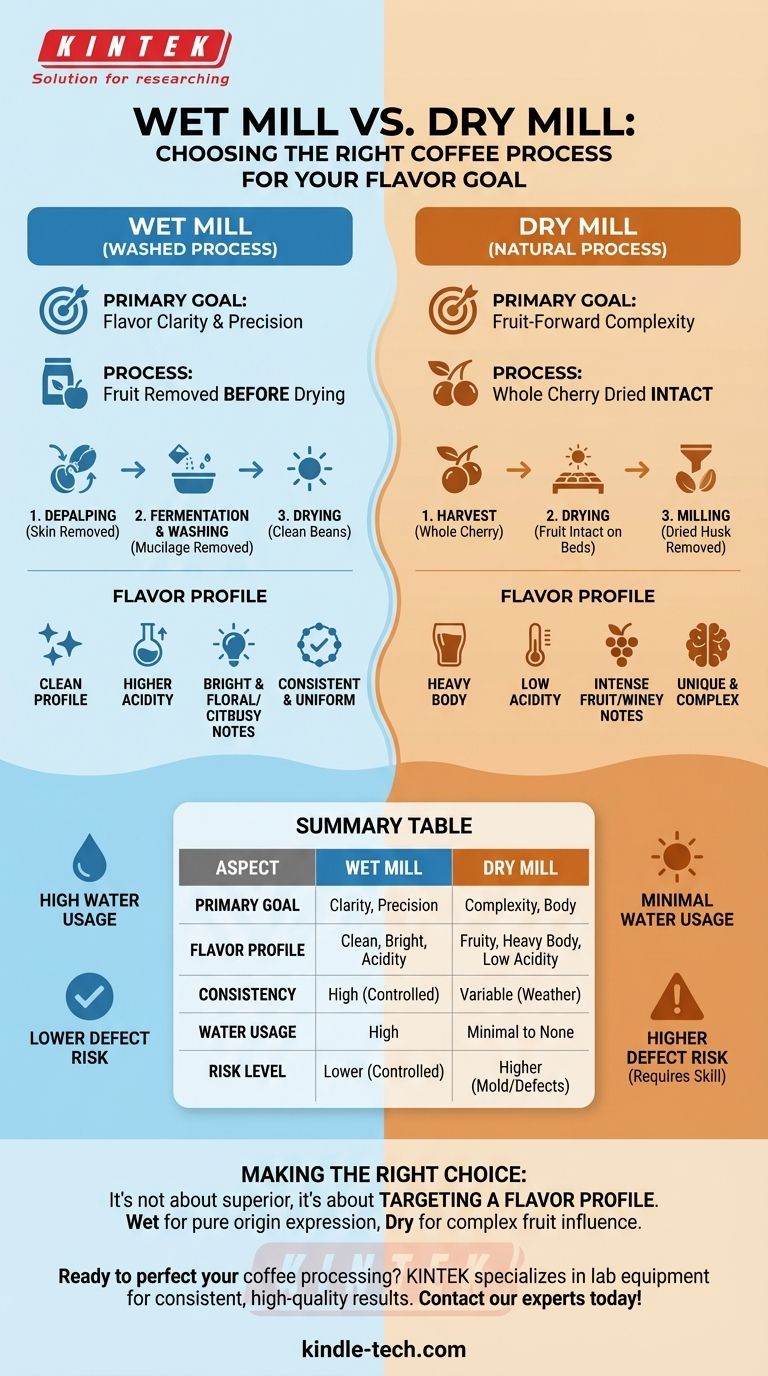

Summary Table:

| Aspect | Wet Mill (Washed Process) | Dry Mill (Natural Process) |

|---|---|---|

| Primary Goal | Flavor clarity and precision | Fruit-forward complexity |

| Flavor Profile | Clean, bright, higher acidity | Heavy body, low acidity, fruity |

| Consistency | High (controlled process) | Variable (weather-dependent) |

| Water Usage | High | Minimal to none |

| Risk Level | Lower (controlled fermentation) | Higher (risk of mold/defects) |

Ready to perfect your coffee processing? Whether you're aiming for the clean, bright profiles of wet milling or the complex fruit notes of natural processing, having the right equipment is crucial. At KINTEK, we specialize in lab equipment and consumables for coffee producers and researchers. From precise fermentation tanks to reliable drying analyzers, our solutions help you achieve consistent, high-quality results. Contact our experts today to discuss how we can support your specific coffee processing needs and elevate your product quality.

Visual Guide

Related Products

- lab cryogenic grinding use liquid-nitrogen for pulverizing plastic raw materials and heat sensitive materials

- Laboratory Ball Mill Jar Mill with Metal Alloy Grinding Jar and Balls

- Laboratory Single Horizontal Jar Mill

- Laboratory Grinding Mill Mortar Grinder for Sample Preparation

- Laboratory Four-Body Horizontal Jar Mill

People Also Ask

- What are the advantages of using 1mm zirconia milling balls? Optimize SnO2 and Li2SnO3 Anode Synthesis

- What function do high-hardness tool steel grinding jars and balls serve in mechanical alloying? Master Kinetic Transfer

- What role does a high-shear homogenizer play in ODC catalyst suspensions? Unlock Superior Electrochemical Efficiency

- What is the function of a high-energy ball mill in the synthesis of LPS? Unlock High Ionic Conductivity Today

- How does a high-energy ball mill facilitate solid-solution alloying? Unlock Advanced HEA Synthesis Techniques

- What is the function of an eccentric shaft mixer? Solve Nano-Agglomeration in Composite Powders

- What is sample pulverizing? The Key to Accurate and Reliable Lab Analysis

- What is the function of an agate mortar in CoFe2O4 synthesis? Achieve Ultra-Pure & Homogeneous Powder Processing