In short, platinum is used for epidural electrodes because it offers the best combination of biocompatibility, electrical efficiency, and long-term stability available. Its unique properties allow it to safely and effectively deliver therapeutic electrical signals to sensitive neural tissue, like the spinal cord, without degrading or causing harm to the body over many years.

The core challenge in designing an implantable electrode is finding a material that can both interact with the body's delicate electrical system and withstand its corrosive environment. Platinum and its alloys are the gold standard because they excel at delivering a precise electrical charge without creating toxic byproducts, ensuring both patient safety and therapeutic effectiveness.

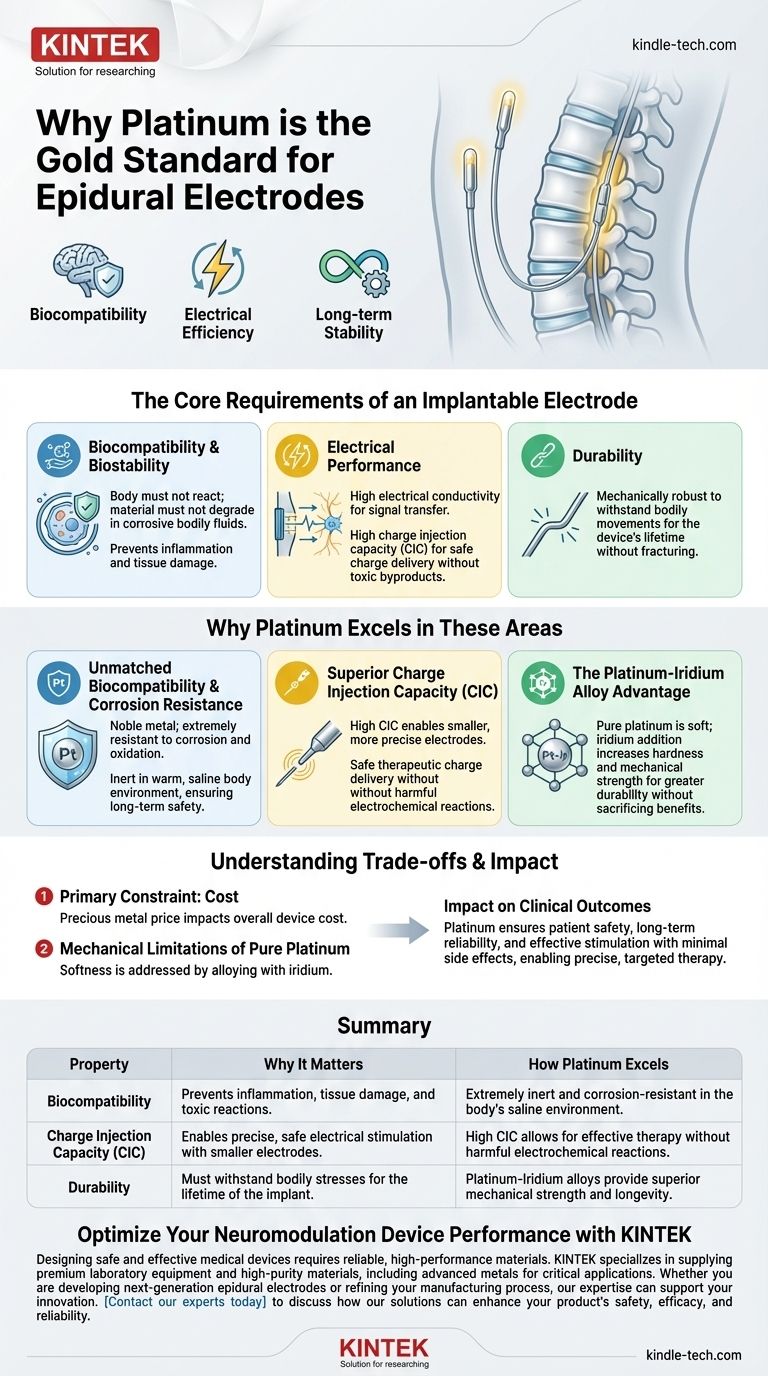

The Core Requirements of an Implantable Electrode

To understand why platinum is the material of choice, we must first define the demanding requirements for any material placed in long-term contact with the central nervous system.

Biocompatibility: The Non-Negotiable Foundation

The electrode material must be biocompatible and biostable. This means the body must not react to it, and the material must not be corroded or degraded by the body's fluids.

Any chemical reaction can lead to inflammation, tissue damage, or a loss of therapeutic effect. The material must be fundamentally inert.

Electrical Performance: Delivering the Signal

The electrode's primary job is to transfer an electrical charge from the device to the nerve tissue. This requires two key properties.

First is high electrical conductivity, which allows the signal to travel with minimal loss.

Second, and more importantly, is a high charge injection capacity (CIC). This is the ability to deliver a sufficient electrical charge without causing irreversible electrochemical reactions (like creating toxic substances or gassing) at the electrode-tissue interface.

Durability: Surviving Within the Body

An epidural electrode is a permanent implant. It must be mechanically robust enough to withstand the minor movements and stresses within the body for the lifetime of the device without fracturing or failing.

Why Platinum Excels in These Areas

Platinum and its alloys meet these demanding criteria better than nearly any other material.

Unmatched Biocompatibility and Corrosion Resistance

Platinum is a noble metal, meaning it is extremely resistant to corrosion and oxidation.

The body is a warm, saline environment that is highly corrosive to most metals. Platinum's inertness ensures it will not break down, release harmful ions into the body, or lose its effectiveness over time.

Superior Charge Injection Capacity (CIC)

This is platinum's most critical electrical advantage. Its high CIC allows engineers to design smaller, more precise electrodes.

A smaller electrode with high CIC can deliver the necessary therapeutic charge safely. Without this property, a larger electrode would be needed to avoid unsafe reactions, reducing the precision of the stimulation.

The Platinum-Iridium Alloy Advantage

You will often see platinum-iridium (Pt-Ir) alloys used, not just pure platinum.

While pure platinum is exceptionally biocompatible and electrically efficient, it is also relatively soft. Adding a small amount of iridium significantly increases the material's hardness and mechanical strength, making the electrode far more durable without sacrificing its critical benefits.

Understanding the Trade-offs

No material choice is without its compromises, and it is important to understand the limitations associated with platinum.

The Primary Constraint: Cost

Platinum is a precious metal. Its high cost is a significant factor in the overall price of advanced medical devices like spinal cord stimulators. This expense is a major driver for research into alternative, lower-cost materials.

Mechanical Limitations of Pure Platinum

As mentioned, pure platinum's softness can be a liability for the fine wires and contacts in an electrode. This is why it is almost always alloyed with iridium to achieve the necessary stiffness and tensile strength for a durable, long-term implant.

How Material Choice Impacts Clinical Outcomes

Your understanding of these principles directly translates to the quality and safety of the therapy delivered.

- If your primary focus is patient safety and long-term reliability: Platinum's inertness and corrosion resistance are the most critical factors, ensuring the device remains safe and functional for years.

- If your primary focus is effective stimulation with minimal side effects: Platinum's high charge injection capacity is key, as it allows for precise, targeted therapy from a small electrode without damaging surrounding tissue.

- If your primary focus is device design and manufacturing: The use of platinum-iridium alloys represents the optimal trade-off between electrical performance, biocompatibility, and the mechanical durability needed for a successful implant.

Ultimately, the selection of platinum reflects a fundamental commitment to maximizing patient safety and therapeutic effectiveness in advanced neuromodulation.

Summary Table:

| Property | Why It Matters for Epidural Electrodes | How Platinum Excels |

|---|---|---|

| Biocompatibility | Prevents inflammation, tissue damage, and toxic reactions. | Extremely inert and corrosion-resistant in the body's saline environment. |

| Charge Injection Capacity (CIC) | Enables precise, safe electrical stimulation with smaller electrodes. | High CIC allows for effective therapy without harmful electrochemical reactions. |

| Durability | Must withstand bodily stresses for the lifetime of the implant. | Platinum-Iridium alloys provide superior mechanical strength and longevity. |

Optimize Your Neuromodulation Device Performance with KINTEK

Designing safe and effective medical devices requires reliable, high-performance materials. KINTEK specializes in supplying premium laboratory equipment and high-purity materials, including advanced metals for critical applications.

Whether you are developing next-generation epidural electrodes or refining your manufacturing process, our expertise can support your innovation.

Contact our experts today to discuss how our solutions can enhance your product's safety, efficacy, and reliability.

Visual Guide

Related Products

- Rotating Platinum Disk Electrode for Electrochemical Applications

- Platinum Auxiliary Electrode for Laboratory Use

- Platinum Sheet Electrode for Laboratory and Industrial Applications

- RRDE rotating disk (ring disk) electrode / compatible with PINE, Japanese ALS, Swiss Metrohm glassy carbon platinum

- Copper Sulfate Reference Electrode for Laboratory Use

People Also Ask

- How should a platinum disk electrode be used during an experiment? A Guide to Accurate Electrochemical Measurements

- Why is a platinum wire (PtW) counter electrode preferred for cathode LSV tests? Ensure High-Precision Research

- What are the advantages of selecting platinum foil as a counter electrode? Ensure Precision in Ni-Cr Alloy Experiments

- What are the performance characteristics of a platinum mesh electrode? Maximize Electrochemical Efficiency

- What is the function of a three-electrode system? Master Precision Film Growth for CP Sensors

- What precautions should be taken regarding the insertion depth of a platinum wire electrode? Ensure Accurate Electrochemical Measurements

- What are the primary applications of glassy carbon? Leverage Its Unique Properties for Demanding Applications

- How should a glassy carbon electrode be polished? A Step-by-Step Guide to a Perfect Electrochemical Surface