The fundamental reason sputtering is superior for alloy deposition is that it is a physical process, not a thermal one. Unlike methods that rely on melting and evaporation, sputtering uses ion bombardment to physically eject atoms from a source target, preserving the original material's precise composition in the deposited thin film.

The critical insight is that sputtering acts like a subatomic sandblaster, knocking atoms loose regardless of their individual properties. This non-selective removal ensures that the ratio of elements in the sputtered film is nearly identical to the source alloy, a feat that is often impossible with heat-based methods.

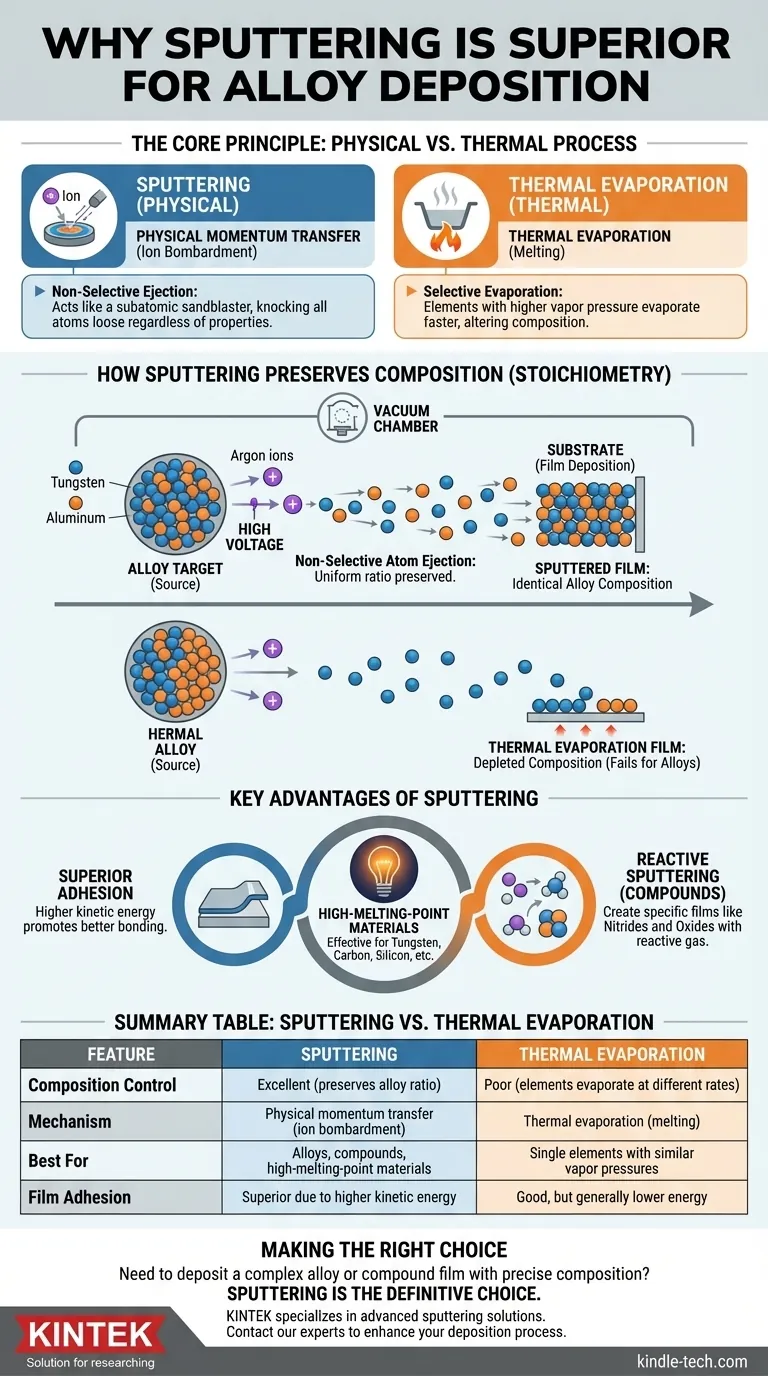

The Core Principle: Momentum Transfer vs. Thermal Evaporation

Sputtering's effectiveness with alloys comes down to how atoms are liberated from the source material. The mechanism is fundamentally different from thermal evaporation, which is often unsuitable for multi-element materials.

How Sputtering Works

Sputtering takes place in a vacuum chamber filled with an inert gas, typically Argon. A high voltage is applied, creating a plasma and accelerating the positive Argon ions toward the source material, known as the target.

These high-energy ions bombard the target, and through a process of momentum transfer, they physically knock atoms or molecules off the target surface. These ejected atoms then travel through the chamber and deposit onto the substrate, forming a thin film.

Why This Preserves Alloy Composition

The key is that this ejection is non-selective. The ion bombardment is a physical collision that doesn't rely on the thermal properties of the individual elements within the alloy target.

Whether an atom is tungsten or aluminum, the impact of the Argon ion has a similar effect. This ensures that the stream of vapor leaving the target has the same relative composition—or stoichiometry—as the target itself.

The Failure Point of Thermal Evaporation

Thermal evaporation, the primary alternative, works by heating the source material in a vacuum until it evaporates, creating a vapor that condenses on the substrate. This process fails for most alloys.

Different elements have vastly different vapor pressures, meaning they evaporate at different rates at a given temperature. When heating an alloy, the element with the higher vapor pressure will evaporate much faster, resulting in a film that is disproportionately rich in that one element and depleted in the others. The composition of the film will not match the source.

Key Advantages and Trade-offs of Sputtering

Understanding why sputtering maintains stoichiometry is the first step. Recognizing its other practical benefits and limitations provides a complete picture for making an informed decision.

Superior Film Adhesion

Sputtered atoms arrive at the substrate with significantly more kinetic energy than evaporated atoms. This higher energy promotes better bonding and diffusion into the substrate surface, resulting in films with superior adhesion.

Depositing High-Melting-Point Materials

Because sputtering does not rely on melting, it is exceptionally effective for depositing materials with extremely high melting points, such as carbon, silicon, or refractory metals like tungsten. These are difficult or impossible to deposit using thermal evaporation.

Control Through Reactive Sputtering

The principle of compositional control can be extended even further. By introducing a reactive gas (like nitrogen or oxygen) into the chamber along with the inert gas, one can create highly specific compound films. For example, sputtering a titanium target in a nitrogen atmosphere produces a hard, durable film of titanium nitride (TiN).

Limitations to Consider

No process is perfect. Sputtering is generally slower than thermal evaporation. It also requires a vacuum environment and a high-voltage power supply, which can make the equipment more complex. Finally, the target and substrate must be relatively close, which can limit some geometric configurations.

Making the Right Choice for Your Goal

Your choice of deposition method must be driven by the final properties your film requires.

- If your primary focus is a precise alloy or multi-element composition: Sputtering is the definitive choice, as its physical ejection mechanism is the only reliable way to preserve the source material's stoichiometry.

- If your primary focus is a simple, high-purity single-element film: Thermal evaporation can be a faster, simpler, and more cost-effective solution, provided the material has a reasonable vapor pressure.

- If your primary focus is a specific compound film (e.g., an oxide or nitride): Reactive sputtering offers unparalleled control for creating films with precise chemical compositions and desired material properties.

Ultimately, selecting the right deposition technique requires understanding how the physics of the process will influence the integrity of your final material.

Summary Table:

| Feature | Sputtering | Thermal Evaporation |

|---|---|---|

| Composition Control | Excellent (preserves alloy ratio) | Poor (elements evaporate at different rates) |

| Mechanism | Physical momentum transfer (ion bombardment) | Thermal evaporation (melting) |

| Best For | Alloys, compounds, high-melting-point materials | Single elements with similar vapor pressures |

| Film Adhesion | Superior due to higher kinetic energy of atoms | Good, but generally lower energy |

Need to deposit a complex alloy or compound film with precise composition?

KINTEK specializes in advanced sputtering solutions for laboratory and research applications. Our equipment ensures you achieve the exact stoichiometry and material properties your project demands, from high-performance alloys to specialized compound films like nitrides and oxides.

Contact our experts today to discuss how our sputtering systems can enhance your thin film deposition process and deliver reliable, repeatable results.

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

People Also Ask

- How do PECVD systems improve DLC coatings on implants? Superior Durability and Biocompatibility Explained

- How are thin films deposited? A Guide to PVD vs. CVD Methods for Your Application

- What are the process capabilities of ICPCVD systems? Achieve Low-Damage Film Deposition at Ultra-Low Temperatures

- What is the difference between plasma CVD and thermal CVD? Choose the Right Method for Your Substrate

- Why is a Matching Network Indispensable in RF-PECVD for Siloxane Films? Ensure Stable Plasma and Uniform Deposition