At its core, gold is used for sputtering because of its unique and powerful combination of physical properties. It offers superior electrical conductivity, exceptional resistance to corrosion and tarnish, and allows for the creation of extremely durable, uniform thin films that are ideal for high-performance applications in science and industry.

Gold is the material of choice when failure is not an option. Its chemical inertness and electrical conductivity make it a premium coating for critical components where long-term reliability and performance are the primary drivers, outweighing its higher material cost.

The Unique Properties of Gold for Sputtering

The decision to use gold is driven by three fundamental characteristics that are difficult to find in a single alternative material.

Unmatched Chemical Inertness

Gold is a noble metal, meaning it is highly resistant to corrosion, oxidation, and acids. This inertness is critical for components exposed to harsh environments or that must maintain pristine surfaces over long periods.

Sputtered gold films do not tarnish and resist degradation, ensuring that their functional properties remain stable for the lifetime of the device. This is vital for medical implants and sensitive electronic connectors.

Superior Electrical Conductivity

Gold is one of the best electrical conductors available. When deposited as a thin film via sputtering, it provides a reliable path for electricity with minimal resistance.

This property is essential for the electronics industry, where gold coatings are applied to circuit boards, connectors, and semiconductor components to ensure a flawless electrical signal.

Exceptional Durability and Appearance

Sputtered gold films are remarkably hard and adhere strongly to the underlying material, or substrate. This means they do not rub off or wear away easily, even with repeated contact.

This durability, combined with gold's timeless sheen, makes it perfect for high-end decorative applications like watches and jewelry, as well as for protective optical coatings.

How Sputtering Unlocks Gold's Potential

Sputtering is a physical vapor deposition (PVD) process that gives engineers precise control over the coating, making it a perfect match for a high-value material like gold.

Achieving a Perfect, Uniform Film

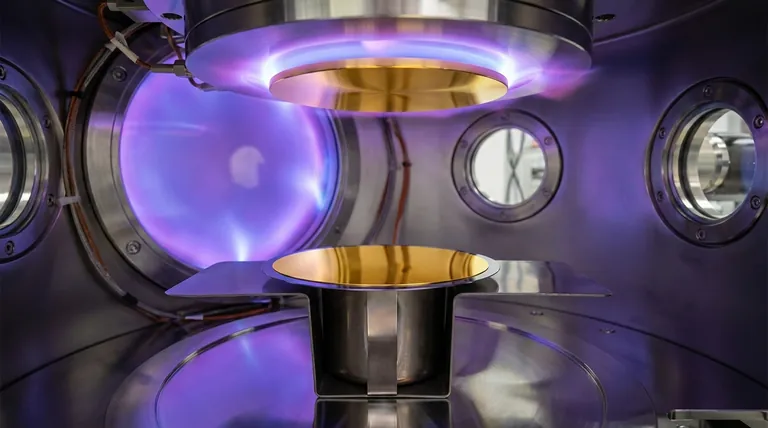

In sputtering, a high-energy ion beam bombards a solid gold "target." This impact ejects, or "sputters," individual gold atoms, which then travel and deposit onto a substrate in a highly controlled vacuum environment.

This method allows for the creation of an exceptionally thin and uniform layer across the entire surface. Technicians can precisely manage the film's thickness and even create custom patterns.

The Role of Magnetron Sputtering

Modern systems often use magnetron sputtering. This technique uses powerful magnetic fields to trap electrons near the gold target, which intensifies the plasma and dramatically increases the rate of sputtering.

This enhancement makes the process more efficient, allowing for faster deposition without raising pressure, which could compromise the quality of the film.

Understanding the Trade-offs

While gold offers premium performance, it is not the right choice for every application. Its benefits must be weighed against its significant drawbacks.

The Primary Factor: Material Cost

The most obvious limitation is cost. Gold is an expensive precious metal, and using it as a sputtering target represents a significant financial investment.

For applications that are highly cost-sensitive or do not require gold's extreme level of performance, alternative materials like copper, aluminum, or titanium are often chosen.

Process Complexity and Investment

Sputtering systems, particularly advanced radio-frequency (RF) systems used for certain materials, can be expensive to purchase and operate. They require a significant capital investment and skilled technicians to run effectively.

While the process offers unparalleled control, the initial barrier to entry in terms of equipment and expertise is higher than for some other coating methods.

Making the Right Choice for Your Application

Selecting gold sputtering depends entirely on your project's non-negotiable requirements.

- If your primary focus is mission-critical electronics or scientific instruments: Use gold for its unmatched conductivity and inertness to guarantee signal integrity and prevent corrosion.

- If your primary focus is biocompatibility and long-term durability: Use gold for medical implants or high-end decorative items that must resist wear and remain chemically stable.

- If your primary focus is cost reduction on a general-purpose component: Avoid gold and explore more economical sputtered materials like aluminum, copper, or chromium.

Ultimately, choosing gold sputtering is an investment in certainty, ensuring your component performs flawlessly under the most demanding conditions.

Summary Table:

| Property | Benefit for Sputtering |

|---|---|

| Chemical Inertness | Resists corrosion, oxidation, and tarnish for long-term reliability. |

| Superior Electrical Conductivity | Ensures flawless signal transmission in electronics. |

| Exceptional Durability | Creates hard, wear-resistant films with strong adhesion. |

| Uniform Thin Films | Sputtering allows for precise, consistent coating deposition. |

Ready to enhance your project's performance with gold sputtering?

KINTEK specializes in providing high-quality lab equipment and consumables, including sputtering targets and systems, to meet the demanding needs of laboratories and high-tech industries. Our expertise ensures you get the right solution for applications requiring superior conductivity, corrosion resistance, and durable coatings.

Contact us today to discuss how our gold sputtering solutions can bring reliability and excellence to your critical applications!

Visual Guide

Related Products

- Evaporation Boat for Organic Matter

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- CVD Diamond Domes for Industrial and Scientific Applications

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

- Laboratory Small Constant Temperature Heated Magnetic Stirrer Heater and Stirrer

People Also Ask

- How is deposition time calculated? Mastering the Clock for Strategic Legal Advantage

- How is energy converted into biomass? Harnessing Nature's Solar Power for Renewable Energy

- How long does it take for THC to evaporate? The Real Science Behind Potency Loss

- What is the widely used boat made of in thermal evaporation? Choosing the Right Material for High-Purity Deposition

- How does a molybdenum evaporation source function in H2S for MoS2 synthesis? Master Reactive Film Deposition