PTFE material

Custom PTFE Teflon Parts Manufacturer Corrosion-Resistant Cleaning Rack Flower Basket

Item Number : PTFE-20

Price varies based on specs and customizations

- Material

- PTFE

- Specification

- See the form

Shipping:

Contact us to get shipping details Enjoy On-time Dispatch Guarantee.

Introduction

PTFE flower baskets (Teflon flower baskets) are made of high-purity experimental grade PTFE, with excellent chemical stability, corrosion resistance, sealing and high and low temperature resistance (-180°C to +250°C).

We provide customized services such as PTFE cleaning racks and flower baskets for glass substrates (such as ITO, FTO, silicon wafers, etc.), and provide free design and drawing services based on your description or sketch to ensure that various industry needs are met.

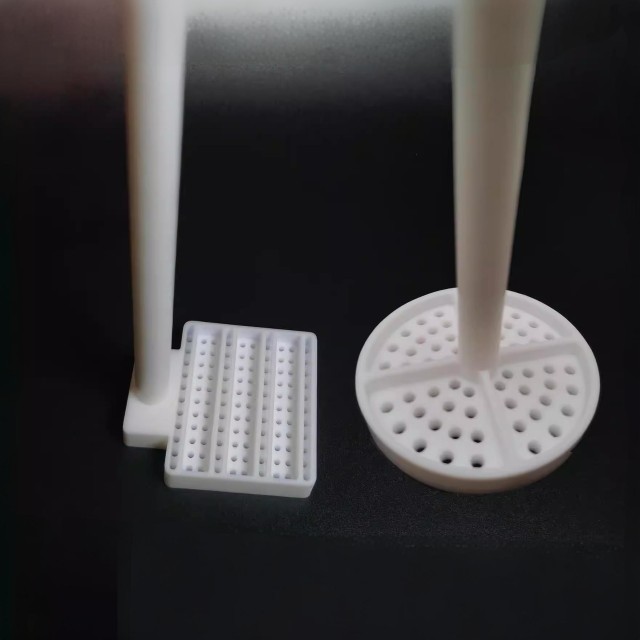

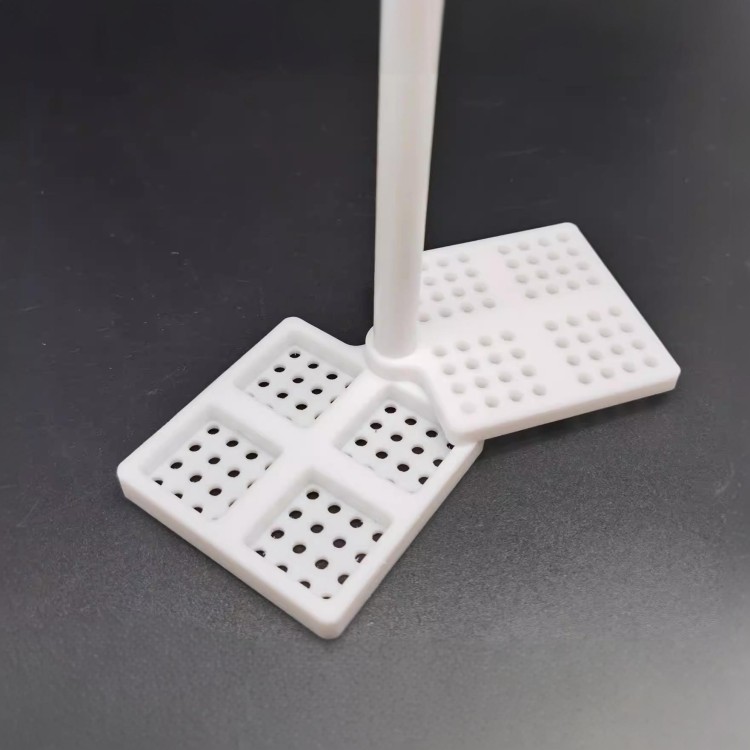

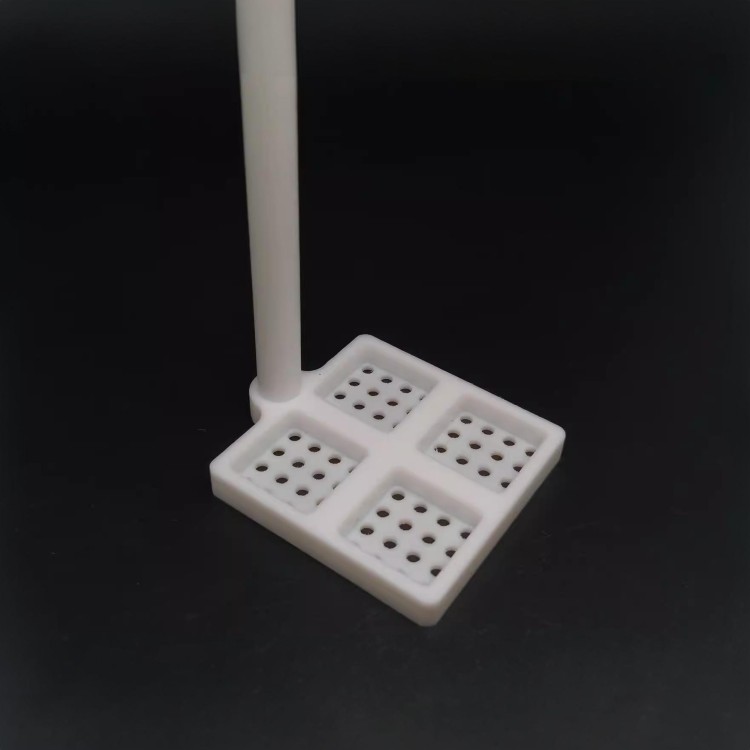

Details & Parts

Technical specifications

| Model | Size | Applicable |

|---|---|---|

| Square |

60mm*60mm |

500ml beaker |

| Round | Diameter 30mm | 75ml beaker |

| Round | Diameter 45mm | 100ml beaker |

| Round | Diameter 60mm | 250ml beaker |

| We provide custom cleaning flower baskets in all sizes you need | ||

Applications

The PTFE cleaning rack, also known as a conductive glass silicon wafer PTFE flower basket cleaning flower basket, is a specialized tool designed for the meticulous cleaning and handling of delicate materials such as silicon wafers and other precision components. This product is particularly useful in environments where cleanliness and precision are paramount, such as in semiconductor manufacturing, electronics production, and research laboratories. The main applications of this product include:

- Semiconductor Manufacturing: Used for cleaning silicon wafers and other semiconductor materials, ensuring they are free from contaminants that could affect the performance of integrated circuits.

- Electronics Production: Ideal for handling and cleaning components used in the production of electronic devices, enhancing the reliability and longevity of the final products.

- Research Laboratories: Essential for researchers working with sensitive materials, providing a controlled environment to prevent contamination and ensure accurate results.

- Pharmaceutical Industry: Helps in the cleaning of equipment and tools used in the production of pharmaceuticals, maintaining high standards of hygiene and precision.

- Optics and Photonics: Used for cleaning optical components and photonic devices, ensuring clarity and performance in high-precision applications.

These applications highlight the versatility and robustness of the PTFE cleaning rack in various industries, ensuring efficient and safe handling of materials under diverse conditions.

Features

- Chemical Resistance: The PTFE material used in the cleaning rack ensures compatibility with a wide range of chemicals, including aggressive substances like hydrofluoric acid. This makes it ideal for laboratories handling diverse chemical compounds without the risk of degradation or contamination.

- High Temperature Resistance: Capable of withstanding temperatures up to 260°C, the PTFE cleaning rack is suitable for use in environments where high-temperature sterilization or cleaning processes are required. This feature ensures that the rack maintains its integrity and functionality under extreme conditions.

- Optical Clarity: The transparency of PTFE allows for easy visual inspection of the items being cleaned, ensuring that all contaminants are effectively removed. This is particularly useful in laboratories where cleanliness and clarity are crucial.

- Durability and Safety: Unlike glass, PTFE does not break, reducing the risk of injury and contamination in the laboratory. The material's low friction coefficient also contributes to its durability, making it a long-lasting solution for laboratory cleaning needs.

Designed for You

KinTek provide deep custom made service and equipment to worldwide customers, our specialized teamwork and rich experienced engineers are capable to undertake the custom tailoring hardware and software equipment requirements, and help our customer to build up the exclusive and personalized equipment and solution!

Would you please drop your ideas to us, our engineers are ready for you now!

FAQ

What Is Polytetrafluoroethylene (PTFE)?

What Are The Key Properties And Characteristics Of PTFE?

What Are The Applications Of PTFE?

What Are The Advantages Of Using PTFE?

Are There Any Limitations Or Considerations When Using PTFE?

4.8

out of

5

Exceeded my expectations! The chemical resistance and durability of this cleaning rack make it an essential tool in our lab.

4.9

out of

5

Impressive value for money. The ability to customize sizes and styles meets our diverse cleaning needs with precision.

4.7

out of

5

Outstanding versatility! The optical clarity and non-contaminating nature offer efficiency and safety in handling delicate materials.

4.8

out of

5

Top-notch quality and durability. The low coefficient of friction and ease of sterilization ensure long-lasting, effective use in our lab.

4.9

out of

5

Excellent precision tool! The customizable options and temperature tolerance provide reliable and cost-effective cleaning.

4.7

out of

5

Impressive chemical resistance! It maintains integrity and safety during cleaning, crucial for our sensitive materials.

4.8

out of

5

Fantastic versatility! It's an indispensable asset in our lab, ensuring safe, efficient, and precise cleaning.

4.9

out of

5

Exceptional safety features. The customizable sizes and stability make it an essential and reliable tool in our lab.

4.7

out of

5

Highly reliable and durable. Its versatility and ease of sterilization provide efficiency and safety in our lab.

4.8

out of

5

Remarkable value! The optical clarity and non-contamination ensure precision and safety in handling delicate materials.

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Products

Custom PTFE Teflon Parts Manufacturer for Cleaning Racks

PTFE cleaning racks are mainly made of tetrafluoroethylene. PTFE, known as the "King of Plastics", is a polymer compound made of tetrafluoroethylene.

PTFE cleaning racks are mainly made of tetrafluoroethylene. PTFE, known as the "King of Plastics", is a polymer compound made of tetrafluoroethylene.

Custom PTFE Teflon Parts Manufacturer for Hollow Cleaning Basket and Rack Carrier

The PTFE hollow cleaning flower basket is a specialized laboratory tool designed for efficient and safe cleaning processes. Made from high-quality polytetrafluoroethylene (PTFE), this basket offers exceptional resistance to acids, alkalis, and organic solvents, ensuring durability and reliability in various chemical environments.

Custom PTFE Teflon Parts Manufacturer for PTFE Containers

PTFE container is a container with excellent corrosion resistance and chemical inertness.

Custom PTFE Teflon Parts Manufacturer for PTFE Tweezers

PTFE tweezers inherit the excellent physical and chemical properties of PTFE, such as high temperature resistance, cold resistance, acid and alkali resistance, and corrosion resistance to most organic solvents.

Custom PTFE Teflon Parts Manufacturer for Conductive Glass Substrate Cleaning Rack

The PTFE conductive glass substrate cleaning rack is used as the carrier of the square solar cell silicon wafer to ensure efficient and pollution-free handling during the cleaning process.

Custom PTFE Teflon Parts Manufacturer for PTFE Measuring Cylinder 10/50/100ml

PTFE measuring cylinder are a rugged alternative to traditional glass cylinders. They are chemically inert over a wide temperature range (up to 260º C), have excellent corrosion resistance and maintain a low coefficient of friction, ensuring ease of use and cleaning.

Custom Machined and Molded PTFE Teflon Parts Manufacturer with PTFE Crucible and Lid

PTFE crucibles, made from pure Teflon, offer chemical inertness and resistance from -196°C to 280°C, ensuring compatibility with a wide range of temperatures and chemicals. These crucibles feature machine-finished surfaces for easy cleaning and prevention of contamination, making them ideal for precise laboratory applications.

Custom PTFE Teflon Parts Manufacturer Adjustable Height Flower Basket

The flower basket is made of PTFE, which is a chemically inert material. This makes it resistant to most acids and bases, and it can be used in a wide variety of applications.

Custom PTFE Teflon Parts Manufacturer for Gaskets and More

Gaskets are materials placed between two flat surfaces to enhance the seal. To prevent fluid leakage, sealing elements are arranged between static sealing surfaces.

Custom PTFE Teflon Parts Manufacturer for PTFE Buchner Funnel and Triangular Funnel

The PTFE funnel is a piece of laboratory equipment used primarily for filtration processes, particularly in the separation of solid and liquid phases in a mixture. This setup allows for efficient and rapid filtration, making it indispensable in various chemical and biological applications.

Custom PTFE Teflon Parts Manufacturer for PTFE Ball Valve Seat

Seats and inserts are vital components in the valve industry. As a key component, polytetrafluoroethylene is usually selected as the raw material.

Custom PTFE Teflon Parts Manufacturer for PTFE Stirring Bar Recovery Rod

This product is used for stirrer recovery, and is resistant to high temperature, corrosion, and strong alkali, and is almost insoluble in all solvents. The product has a stainless steel rod inside and a polytetrafluoroethylene sleeve outside.

Custom PTFE Teflon Parts Manufacturer for Centrifuge Tube Racks

The precision-made PTFE test tube racks are completely inert and, due to the high temperature properties of PTFE, these test tube racks can be sterilized (autoclaved) without any problems.

Custom PTFE Teflon Parts Manufacturer for Centrifuge Tubes

PTFE centrifugal tubes are highly valued for their exceptional chemical resistance, thermal stability, and non-stick properties, making them indispensable in various high-demand sectors. These tubes are particularly useful in environments where exposure to corrosive substances, high temperatures, or stringent cleanliness requirements are prevalent.

Custom PTFE Teflon Parts Manufacturer for ITO FTO Glass and Silicon Wafer Storage Turnover Racks

ITO/FTO glass storage rack/turnover rack/silicon wafer storage rack can be used for the shipment packaging, turnover and storage of silicon wafers, chips, germanium wafers, glass wafers, sapphire wafers, quartz glass and other materials.

Custom PTFE Teflon Parts Manufacturer Grinding Bowl

PTFE is renowned for its exceptional chemical resistance, thermal stability, and low friction properties, making it a versatile material in various industries. The PTFE grinding bowl, specifically, finds applications where these properties are crucial.

Custom PTFE Teflon Parts Manufacturer for Three-Necked Round Bottom Flask

PTFE flask, is a versatile laboratory container made from PTFE, offering exceptional chemical resistance, temperature stability, and non-stick properties. Ideal for handling corrosive substances and high-temperature applications, these flasks are essential in various laboratory procedures, including heating, mixing, and storage of chemicals.

Acid and alkali resistant polytetrafluoroethylene experimental fixtures meet different requirements. The material is made of brand new polytetrafluoroethylene material, which has excellent chemical stability, corrosion resistance, airtightness, high lubricity and non-stickiness, electrical corrosion and good anti-aging ability, and can work for a long time at temperatures from -180℃ to +250℃.

Related Articles

Applications of Dry Cold Traps in Various Processes

Dry cold traps are used in multiple applications to condense and collect gases, protecting equipment and improving process efficiency.

Basic Laboratory Purification Equipment Overview

An overview of essential purification equipment used in laboratories, including water purification, solvent evaporation, and waste treatment systems.