Introduction to Rotary Evaporators

Definition and Function

A rotary evaporator is an essential laboratory tool designed to facilitate the removal of solvents or the extraction of substances from complex mixtures. This process begins with the heating of the liquid mixture, which causes the solvents or target substances to vaporize. These vapors are then condensed, typically through a cooling system, resulting in the collection of purified substances. The rotary action ensures even heating and efficient evaporation, making it a highly effective method for solvent removal and substance extraction.

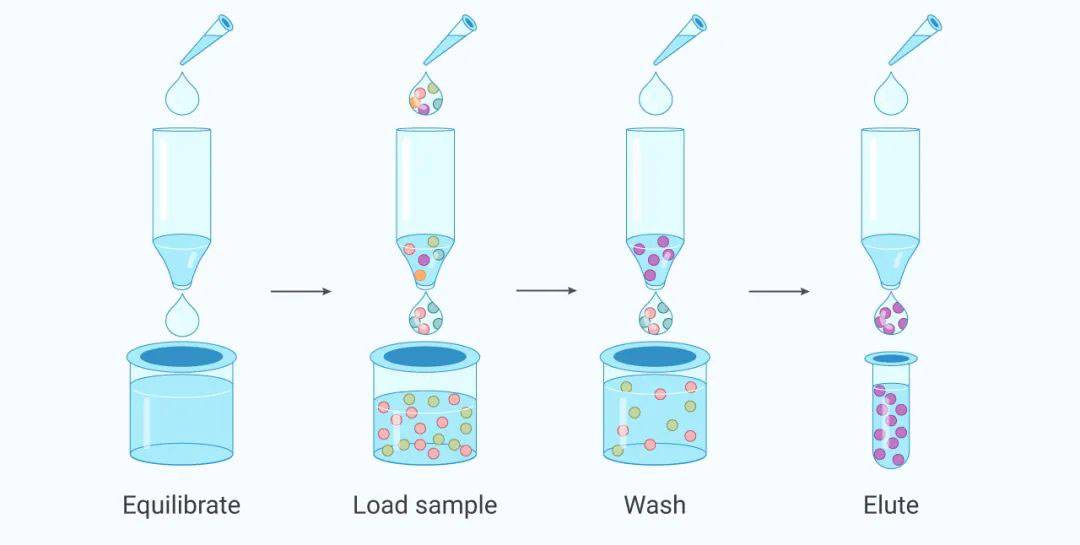

The core function of a rotary evaporator involves several key steps:

- Heating: The liquid mixture is placed in a rotating flask immersed in a heating bath. The heat provided by the bath causes the solvents or target substances to vaporize.

- Rotation: The continuous rotation of the flask ensures uniform exposure to heat, preventing bumping and promoting efficient evaporation.

- Vacuum System: A vacuum is applied to lower the boiling point of the solvents, allowing for evaporation at lower temperatures and reducing the risk of thermal degradation.

- Condensation: The vapors are directed through a condenser, where they are cooled and converted back into liquid form, which is then collected.

- Purification: The remaining substance in the flask is the purified extract, free from solvents and other impurities.

This multi-step process highlights the precision and efficiency of rotary evaporators in both academic research and industrial applications.

Versatility and Industry Applications

Rotary evaporator equipment is highly versatile, finding applications across a broad spectrum of industries. Its ability to efficiently remove solvents and extract substances makes it indispensable in sectors such as pharmaceuticals, chemicals, and food and beverage.

In the pharmaceutical industry, rotary evaporators are pivotal for drug formulation and purification. They facilitate the extraction of active pharmaceutical ingredients (APIs) with precision, ensuring that the integrity and potency of the drugs remain intact. This equipment can handle a diverse array of solvents and volumes, making it a versatile tool in pharmaceutical research and development.

The chemical industry also benefits significantly from rotary evaporators. These devices are employed in the synthesis and purification of various chemicals, aiding in the production of high-purity substances. The low-pressure environment created by the vacuum system ensures that the evaporation process is both efficient and effective, minimizing the risk of degradation.

In the food and beverage industry, rotary evaporators play a crucial role in creating unique flavors, aromas, and textures. By separating different compounds in a mixture, these devices help in the development of innovative products that meet consumer preferences. The versatility of rotary evaporators in this sector extends to the extraction of essential oils, which are used in a variety of food and beverage applications to enhance taste and aroma.

Overall, the adaptability of rotary evaporators across these industries underscores their importance in modern research and production processes. Their ability to handle diverse solvents and mixtures, coupled with their efficiency and precision, makes them an essential tool in the quest for high-quality, purified substances.

Operational Principles

Components and Mechanism

A rotary evaporator is a sophisticated laboratory device composed of several critical components, each playing a vital role in the solvent removal process. The primary components include a vacuum system, a heating bath, a condenser, and a rotating flask. The solvent or mixture to be separated is carefully added to the rotating flask, which is then submerged in a heating bath. This setup ensures uniform heating, promoting efficient evaporation.

The vacuum system is integral to the operation, as it creates a low-pressure environment within the apparatus. This low-pressure condition significantly lowers the boiling point of the solvent, facilitating its rapid vaporization. The vaporized solvent is then directed through a condenser, where it is cooled and converted back into a liquid state, collected in a separate vessel.

In summary, the rotary evaporator leverages the combined functionality of its components—vacuum system, heating bath, condenser, and rotating flask—to achieve efficient and controlled solvent removal, making it an indispensable tool in various scientific and industrial applications.

Advantages of Rotary Evaporators

Cost-Effectiveness and Integrity Retention

Rotary evaporators stand out as an economically viable solution for solvent removal on a large scale, making them indispensable in both research and industrial settings. By leveraging a combination of vacuum pressure and controlled heating, these devices efficiently separate solvents from the target substances, ensuring minimal loss and maintaining the integrity of the extracted material. This method not only reduces operational costs but also enhances the overall quality of the final product.

Moreover, the design of rotary evaporators, which includes a rotating flask and a condenser, facilitates a continuous flow of solvent vapor that is promptly condensed and collected, thereby maximizing efficiency. This streamlined process not only saves time but also minimizes energy consumption, making it a preferred choice for laboratories and production facilities aiming to optimize their resource usage.

In addition to their cost-effectiveness, rotary evaporators are known for their ability to handle a wide range of solvents and volumes, making them versatile tools across various industries. Whether in the pharmaceutical sector for drug formulation and purification, or in environmental analysis for concentrating hydrocarbons, these devices consistently deliver reliable and high-quality results. Their adaptability ensures that they can cater to diverse needs, from small-scale research to large-scale industrial applications.

Applications in Various Industries

Pharmaceutical Industry

In the pharmaceutical industry, rotary evaporators play a crucial role in the formulation and purification of drugs, as well as the extraction of active ingredients. These devices are capable of handling a wide range of solvents and volumes, making them indispensable in the production process.

The versatility of rotary evaporators allows them to efficiently manage various solvent types, from volatile organic compounds to more stable solvents. This adaptability ensures that pharmaceutical companies can process different drug formulations with precision and consistency. Moreover, the ability to handle large volumes is particularly advantageous for batch processing, where scalability is key to meeting production demands.

Additionally, rotary evaporators contribute to the integrity and purity of the final product. By creating a low-pressure environment, these devices can effectively separate solvents from the mixture without degrading the active pharmaceutical ingredients. This ensures that the drugs retain their therapeutic properties, which is essential for maintaining efficacy and safety.

In summary, rotary evaporators are vital tools in the pharmaceutical industry, offering a robust solution for solvent management, scalability, and product integrity. Their ability to handle diverse solvents and volumes makes them a cornerstone in drug formulation and purification processes.

Environmental Analysis

Rotary evaporators play a crucial role in environmental analysis by efficiently concentrating or extracting petroleum hydrocarbons. This process is essential for identifying and quantifying these compounds in environmental samples, which is vital for assessing pollution levels and understanding the impact of hydrocarbon contaminants on ecosystems.

Unlike traditional solvent extraction methods, rotary evaporators offer a safer and more controlled approach. They operate under reduced pressure, which minimizes the risk of hazardous solvent vapors escaping into the environment. This controlled environment also ensures that the integrity of the extracted hydrocarbons is maintained, providing more accurate and reliable analytical results.

Moreover, rotary evaporators are designed to handle a variety of solvents and sample volumes, making them highly adaptable for different environmental analysis needs. Whether it's analyzing soil samples, water bodies, or atmospheric particulates, these devices can efficiently process the samples, leading to quicker and more precise results.

In summary, rotary evaporators not only enhance the safety and efficiency of environmental analysis but also contribute to more accurate and comprehensive data on hydrocarbon contamination, aiding in the development of effective remediation strategies.

Extraction of Essential Oils

The extraction of essential oils is a sophisticated process that leverages the capabilities of rotary evaporators to achieve a higher concentration of these valuable oils. This method is particularly effective due to the rotary evaporator's ability to create a low-pressure environment, which facilitates the gentle and efficient vaporization of solvents. The process begins with the introduction of a plant material or mixture into the rotating flask, which is then heated. As the mixture is rotated, the vacuum system reduces the pressure, causing the solvent to evaporate quickly.

The condensed vapors are collected and processed to yield a highly concentrated essential oil. This technique not only enhances the concentration of the oils but also preserves their natural properties and aromatic compounds, making them suitable for a wide array of applications, from aromatherapy to culinary uses. The versatility of rotary evaporators ensures that various types of plant materials can be processed, each yielding unique and potent essential oils.

Moreover, the use of rotary evaporators in this process offers several advantages. It is a cost-effective method that can handle large volumes of material, ensuring a consistent and high-quality output. The integrity of the essential oils is retained, which is crucial for maintaining their therapeutic and aromatic qualities. This method also provides a safer alternative to traditional solvent extraction techniques, reducing the risk of contamination and preserving the purity of the final product.

Food and Beverage Industry

In the food and beverage industry, rotary evaporators play a crucial role in crafting distinctive flavors, aromas, and textures. These devices are employed to separate various compounds within a mixture, allowing for the precise manipulation of taste and sensory qualities. The process involves heating the mixture under vacuum conditions, which facilitates the evaporation of solvents while preserving the integrity of the desired compounds.

This technique is particularly valuable in the production of specialty beverages and gourmet foods, where the consistency and quality of flavors are paramount. By isolating and concentrating specific components, manufacturers can achieve a level of customization that is difficult to replicate through traditional methods. For instance, the extraction of natural essences from fruits, herbs, and spices becomes more efficient and controlled, leading to higher-quality end products.

Moreover, rotary evaporators contribute to the development of novel food products by enabling the exploration of new flavor combinations and textures. The ability to manipulate compounds at a molecular level opens up opportunities for innovation, driving advancements in product development and enhancing consumer experiences.

Conclusion

Efficiency and Versatility

The gentle extraction process of rotary evaporators not only preserves the integrity of substances but also ensures efficiency, speed, and cost-effectiveness. This method is particularly advantageous in industries where the quality and purity of the final product are paramount. TOPTION's rotary evaporators are engineered to streamline the process, making it both straightforward and highly efficient. By maintaining a low-pressure environment and controlled heating, these devices minimize the risk of thermal degradation, thereby preserving the chemical and biological properties of the extracted materials.

Moreover, the versatility of rotary evaporators extends across various sectors, including pharmaceuticals, environmental analysis, and the food and beverage industry. In the pharmaceutical sector, for instance, these devices are indispensable for drug formulation and purification, ensuring that active ingredients are extracted with precision and efficiency. Similarly, in environmental analysis, rotary evaporators are utilized to concentrate samples, such as petroleum hydrocarbons, providing a safer and more effective alternative to traditional solvent extraction methods.

The economic benefits of rotary evaporators are equally compelling. By enabling large-scale solvent removal in a cost-effective manner, these devices significantly reduce operational costs without compromising the quality of the final product. This makes rotary evaporators an invaluable tool for laboratories and production facilities looking to optimize their processes and achieve higher yields.

Related Products

- Laboratory Benchtop Water Circulating Vacuum Pump for Lab Use

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Lab Electrochemical Workstation Potentiostat for Laboratory Use

- Custom PTFE Teflon Parts Manufacturer for Sampling Solution Sample and Dry Powder Spoons

Related Articles

- Discover The Benefits of Using A Rotary Evaporator

- The Importance of Water Distillation in the Laboratory: Ensuring Purity and Quality for Accurate Results

- How to Choose Laboratory Vacuum Pumps for Maximum Efficiency and Cost Savings

- Exploring the Science Behind Rotary Evaporators: How They Work and Their Applications

- Step-by-Step Guide to Operating a Short Path Distillation Apparatus