Table of Contents

Introduction to Handheld Alloy Analyzers

Welcome to the Ultimate Guide to Handheld Alloy Analyzers, where we will delve into the revolutionary technology that is revolutionizing quality control in various industries. Handheld alloy analyzers have come a long way, evolving from simple devices to sophisticated instruments capable of fast and accurate analysis. These devices are invaluable in ensuring the quality of materials used in industrial processes, from automotive manufacturing to aerospace and electronics. By leveraging real-time data and cutting-edge technology, these analyzers have become an integral part of quality control efforts, helping businesses to maintain high standards and enhance their production processes. In this guide, we will explore the key features, advantages, and applications of handheld alloy analyzers, comparing them with benchtop models and discussing future trends and innovations in the industry. Join us as we discover how these remarkable devices are shaping the future of quality control.

Key Features of Handheld Alloy Analyzers

Handheld alloy analyzers are revolutionizing the field of metal analysis with their advanced features and capabilities. These devices are designed to provide rapid, accurate results, making them indispensable tools for quality control in various industries.

Mass Production Quality Control

One of the standout features of handheld alloy analyzers is their ability to facilitate mass production quality control. These devices are configured to handle large volumes of samples efficiently, ensuring that each product meets the required standards. They can perform 100% quality control of processed products, which is crucial for maintaining high levels of product integrity and consistency.

Pass/Fail Results

Handheld alloy analyzers are equipped with sophisticated algorithms that enable them to provide immediate pass/fail results. This feature is particularly beneficial in production environments where quick decisions are necessary to maintain workflow and prevent bottlenecks. The ability to instantly determine whether a material meets the specified alloy grade requirements enhances operational efficiency.

Accurate Alloy Grades

Accuracy in identifying alloy grades is paramount in industries such as aerospace, automotive, and electronics, where the use of incorrect materials can have severe consequences. Handheld alloy analyzers utilize advanced XRF spectrometry to accurately identify and grade alloys, ensuring that the materials used are precisely what they are supposed to be.

Material Chemical Composition

Understanding the chemical composition of materials is essential for ensuring their suitability for specific applications. These analyzers can determine the presence and amount of various elements, including trace alloying elements and harmful heavy metals. This capability is crucial for compliance with industry standards and regulations.

Elemental Analysis Range

Handheld alloy analyzers cover a broad elemental analysis range, typically from potassium (K19) to uranium (U92). This wide range allows for the analysis of a vast array of materials, from common metals to rare and precious alloys. The analyzable content range is also extensive, typically from 1ppm to 99.99%, ensuring comprehensive coverage of different material compositions.

Speed of Analysis

The speed at which handheld alloy analyzers can deliver results is a significant advantage. With the ability to identify an alloy grade within 1-2 seconds and provide laboratory-level analysis results in just a few additional seconds, these devices significantly reduce the time required for material testing. This rapid analysis capability is particularly beneficial in high-volume production environments where quick turnaround times are critical.

In conclusion, handheld alloy analyzers offer a suite of features that make them essential tools for modern industries. Their ability to handle mass production quality control, provide immediate pass/fail results, accurately identify alloy grades, and analyze material chemical composition with speed and precision, positions them as indispensable assets in the realm of metal analysis and quality assurance.

Data Management and Connectivity

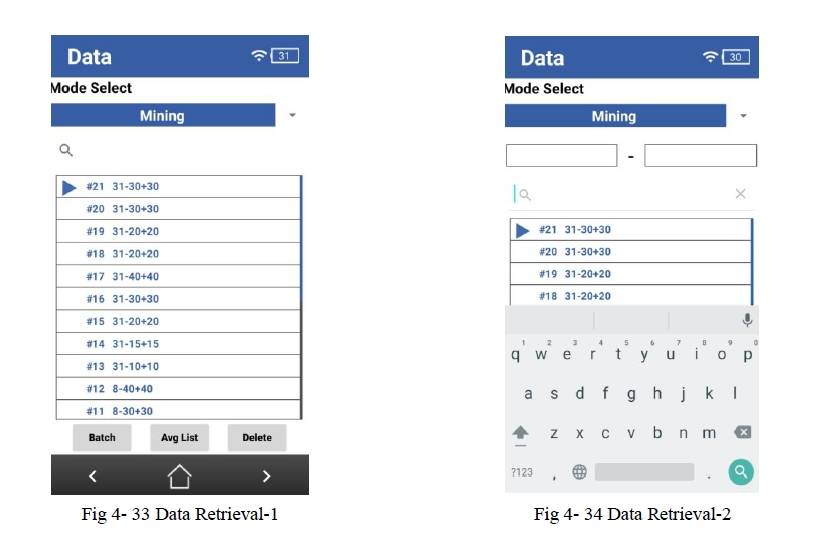

In the realm of industrial applications, the management and connectivity of data are crucial for efficient operations and decision-making. Analyzers equipped with advanced data management systems offer a range of features that enhance productivity and ensure data integrity. These systems minimize data entry and duplication through barcode systems, which not only saves time but also reduces the likelihood of errors.

One of the significant advantages of these analyzers is their ability to instantly produce trend charts and custom reports from the plant’s entire history. This feature is invaluable for monitoring the performance of various processes and making informed decisions based on historical data. Additionally, the ability to restrict which recipes furnaces can process and maintain recipe revision history ensures that the production process is consistent and compliant with specific standards.

The connectivity options provided by these analyzers, such as Ethernet and USB, allow for seamless integration with existing networks and systems. This connectivity enables access to data from multiple computers, facilitating collaborative work environments and real-time monitoring. Real-time monitoring is particularly beneficial as it allows for immediate intervention if any anomalies are detected, thereby preventing potential issues that could disrupt the production process.

Moreover, these systems contribute to reducing audit time by providing a clear and organized trail of data. This efficiency in data management and audit trails not only saves time but also enhances the overall reliability of the data, which is crucial for compliance and quality assurance.

The analyzers are also designed with user-friendly support frameworks, ensuring that accessibility is maintained at all times. The use of open frames in the design makes them more manageable and adaptable to various industrial settings. The furnaces are equipped with internal Ethernet networks, and remote furnace service is available through internet or modem connections, using dedicated software. This remote access capability is a significant advantage, as it allows for troubleshooting and maintenance without the need for physical presence, saving both time and resources.

Optionally, the control system can be equipped with advanced batch reporting and history analyzing software. This software can present data using templates for standard MS Office applications like Word and Excel, making it easier for users to analyze and report on the data. A separate diagnostic screen also reminds about maintenance requirements of individual components of the furnace, ensuring that the equipment is always in optimal condition.

The integration of an energy-efficient Power Management System controls the heating and cooling capacity of the furnaces, optimizing energy use and reducing operational costs. The instrument’s Ethernet (RJ-45 network port) allows for remote real-time monitoring, which is critical for maintaining high standards of quality control and operational efficiency.

In summary, the data management and connectivity features of these analyzers are designed to enhance the efficiency, reliability, and accessibility of industrial processes. By leveraging these advanced features, industries can achieve significant improvements in their operations, ensuring high-quality outcomes and efficient use of resources.

Advantages of Handheld Alloy Analyzers

Handheld alloy analyzers offer a multitude of advantages that make them indispensable tools in various industries, particularly in metal processing and quality control. These devices are renowned for their speed, reliability, and ease of use, which contribute significantly to operational efficiency and cost-effectiveness.

Fast Analysis: One of the standout features of handheld alloy analyzers is their ability to provide rapid results. Utilizing advanced electronics and sophisticated mathematical algorithms, these devices can identify alloy grades within seconds. This rapid analysis capability is crucial for checking incoming materials, finished goods, and in-process production parts without the need for destructive testing. The speed of analysis not only enhances productivity but also allows for immediate decision-making in critical quality control scenarios.

24/7 Operation: Handheld alloy analyzers are designed for continuous operation, making them ideal for 24/7 industrial environments. Equipped with rugged, dust-proof, moisture-proof, and vibration-proof features, these devices can withstand harsh factory conditions and provide uninterrupted service. This durability ensures that production lines can operate at full capacity without the risk of downtime due to equipment failure.

Easy Integration with Robotic Arms or Production Lines: The design of these analyzers facilitates easy integration with robotic arms or existing production lines. Their unique design and interface options, such as Ethernet and USB, allow for seamless connection and operation within automated systems. This integration not only enhances the efficiency of the production process but also reduces the need for manual intervention, thereby minimizing human error and increasing throughput.

Low Maintenance Costs: Another significant advantage of handheld alloy analyzers is their low maintenance costs. These devices are built to last, requiring minimal upkeep and servicing. The rugged construction ensures that they can operate effectively in various environmental conditions without frequent repairs or replacements. This low-maintenance feature significantly reduces operational costs and contributes to the overall cost-effectiveness of using these analyzers in industrial settings.

Quick Recovery of Investment Costs: The combination of fast analysis, continuous operation, easy integration, and low maintenance costs leads to a quick recovery of investment costs. Automated inspection solutions provided by these analyzers help factories significantly reduce manual inspection costs, save analysis time, and improve product manufacturing efficiency. The rapid return on investment is a compelling reason for industries to adopt handheld alloy analyzers in their quality control processes.

In conclusion, handheld alloy analyzers are transformative tools in the field of metal analysis and quality control. Their ability to deliver rapid, accurate results, operate continuously, integrate seamlessly with production systems, and maintain low operational costs make them an invaluable asset in modern industrial settings. The quick recovery of investment costs further underscores their value, making them a strategic choice for businesses aiming to enhance their operational efficiency and competitiveness.

Applications in Various Industries

Handheld alloy analyzers have revolutionized quality control and operational efficiency across multiple industries, including automotive, aerospace, and electronics. These devices, equipped with advanced XRF spectrometry, offer rapid, accurate results, making them indispensable tools for material analysis and grade identification.

In the automotive industry, handheld alloy analyzers are crucial for ensuring the quality and safety of metal components used in vehicle manufacturing. For instance, during the production of critical parts like engine blocks and transmission housings, these analyzers provide real-time material composition data, ensuring that each component meets the required standards for strength and durability. By conducting 100% inspection of these parts, manufacturers can guarantee that all materials used are of the highest quality, thus enhancing the overall safety and reliability of vehicles.

Similarly, in the aerospace sector, the precision and reliability of handheld alloy analyzers are paramount. Aerospace components, such as turbine blades and structural frames, must withstand extreme conditions. These devices enable manufacturers to verify the alloy composition and integrity of these parts quickly and accurately. This capability is particularly important in a sector where even minor deviations in material composition can have significant safety implications.

In the electronics industry, handheld alloy analyzers play a critical role in the quality control of components used in circuit boards and other electronic devices. The devices are used to ensure that the metals used in soldering and other manufacturing processes meet specific purity standards. This is essential for maintaining the performance and longevity of electronic devices. By using these analyzers, electronics manufacturers can quickly identify and reject any substandard materials, thereby reducing the risk of product failure and enhancing customer satisfaction.

Furthermore, handheld alloy analyzers are extensively used in scrap metal recycling, where they help in the rapid identification and sorting of various metal types. This not only improves the efficiency of recycling operations but also ensures that recycled materials are of high enough quality to be reused in new products.

In summary, handheld alloy analyzers have significantly improved quality control and operational efficiency across various industries. Their ability to provide quick, accurate, and non-destructive analysis makes them an essential tool for ensuring the quality and safety of products in sectors where precision and reliability are paramount.

Comparison with Benchtop Analyzers

When comparing handheld alloy analyzers with benchtop models, several key factors come into play, including portability, ease of use, and specific applications such as gold analysis. Each type of analyzer has its own set of advantages and trade-offs that can influence the choice depending on the user's needs and the environment in which the analyzer will be used.

Portability is a significant advantage of handheld alloy analyzers. These devices are designed to be lightweight and compact, allowing for easy transportation to various locations. This makes them ideal for field use, on-site inspections, and situations where mobility is crucial. For instance, in the scrap metal recycling industry, handheld analyzers can quickly identify and sort different types of metals on the go, enhancing efficiency and reducing the need for transporting materials to a fixed testing location.

In contrast, benchtop analyzers, like the XRF 200 Benchtop Gold analyzer, are typically larger and stationary. They are designed for use in laboratories or fixed testing stations where portability is not a primary concern. Benchtop models often offer more advanced features and higher precision due to their larger size and more robust construction, which can be beneficial for detailed analysis and quality control in a controlled environment.

Ease of Use is another critical aspect to consider. Handheld analyzers are generally user-friendly, with simple interfaces and minimal training requirements. They often feature intuitive touch-screen displays that provide quick results, making them suitable for users who need to perform rapid analyses without extensive technical knowledge. This simplicity is particularly useful in industries where non-destructive testing is needed on a variety of materials, such as in the precious metals industry where quick identification of karat values is essential.

Benchtop analyzers, while potentially more complex, are designed to deliver highly accurate and precise results. They often require more setup and possibly more technical expertise to operate effectively. However, the trade-off is enhanced analytical capabilities, which can be crucial for applications that demand high precision, such as in research laboratories or high-stakes quality control environments.

Specific Applications such as gold analysis highlight the strengths of both types of analyzers. Handheld models are excellent for quick, on-site assessments of gold content in jewelry or scrap, providing immediate results that can guide purchasing or refining decisions. Their non-destructive nature is particularly beneficial in this context, as it allows for testing without damaging the valuable materials.

Benchtop analyzers, on the other hand, offer a deeper level of analysis, capable of detecting a broader range of elements and providing more detailed compositional data. This can be essential for comprehensive quality control and detailed analysis of precious metals, where the presence of trace elements can significantly affect the value and properties of the material.

In conclusion, the choice between handheld and benchtop alloy analyzers depends largely on the specific needs of the user, including the required level of precision, the importance of portability, and the nature of the applications. Handheld analyzers excel in mobility and ease of use, making them ideal for on-the-go testing and rapid assessments. Benchtop analyzers, while less portable, offer enhanced precision and analytical capabilities, making them suitable for more detailed and controlled analyses.

Future Trends and Innovations in Handheld Alloy Analyzer Technology

The handheld alloy analyzer market is poised for significant advancements, driven by the need for more efficient, precise, and versatile tools in various industries including mining, quality control, and recycling. Here, we explore the future trends and innovations that are likely to shape the development of these devices.

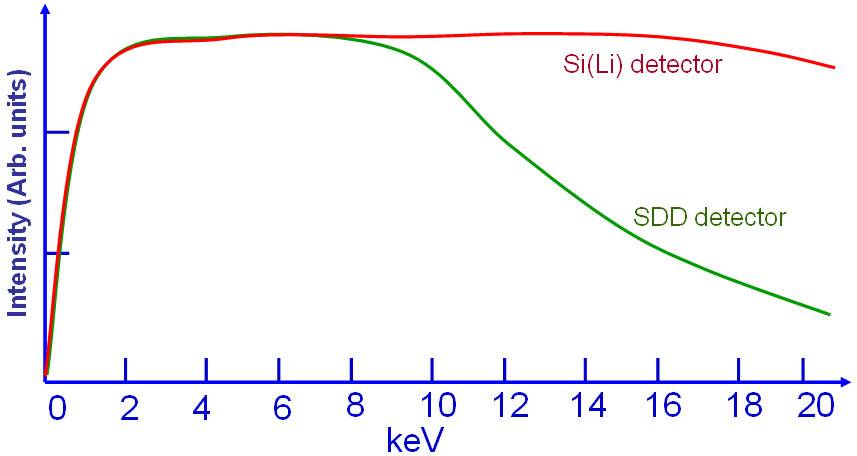

Advancements in Detection Capabilities

Handheld alloy analyzers are expected to see substantial improvements in their detection capabilities. With the integration of advanced technologies such as Silicon Drift Detectors (SDD), these devices can offer higher resolution and count rates, leading to lower detection limits for elements analyzed. This enhancement is crucial for applications where trace elements need to be detected accurately, such as in the analysis of precious metals or harmful heavy metals like cadmium, lead, and indium.

Moreover, the development of more sophisticated algorithms that combine powerful fundamental parameters (FP) and empirical coefficient methods will enable faster and more accurate identification of alloy grades. This technology will allow users to obtain lab-quality analysis results within seconds, a significant improvement over current models.

Miniaturization and Ergonomic Design

The trend towards miniaturization will continue, making handheld alloy analyzers even more compact and portable. This design evolution not only saves space but also enhances the ease of use, particularly in environments where space is limited, such as jewelry stores or on-site mining operations. Ergonomic designs, equipped with features like LED lighting and intuitive user interfaces, will ensure that these devices are easy to operate in various lighting conditions and by users with varying levels of expertise.

Integration with AI and IoT

The integration of Artificial Intelligence (AI) and the Internet of Things (IoT) into handheld alloy analyzers will revolutionize how data is analyzed and used. AI algorithms can process the vast amounts of data generated by these devices to provide predictive analytics, helping users anticipate maintenance needs and optimize their operations. IoT connectivity will allow for real-time data sharing and remote monitoring, enabling more effective collaboration and decision-making across different locations.

For instance, through proprietary data acquisition and processing software, real-time online inspection data can be effectively managed. The instrument, equipped with an Ethernet (RJ-45 network port), can connect with PCs remotely to realize remote real-time monitoring, a feature that is becoming increasingly important in industries where immediate data analysis is critical.

Enhanced Data Management and Connectivity

As handheld alloy analyzers become more sophisticated, the management of the data they produce will also evolve. Future models will likely feature enhanced connectivity options, allowing for seamless integration with other devices and systems. This connectivity will facilitate the implementation of comprehensive quality control systems, where data from multiple devices can be aggregated and analyzed in real-time.

In conclusion, the future of handheld alloy analyzers looks promising, with advancements in detection capabilities, miniaturization, and integration with AI and IoT. These innovations will not only improve the efficiency and accuracy of analyses but also enhance the user experience, making these devices indispensable tools in various industries.

Related Products

- Single Punch Tablet Press Machine and Mass Production Rotary Tablet Punching Machine for TDP

- Lab Electrochemical Workstation Potentiostat for Laboratory Use

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

Related Articles

- In-depth Analysis of Tablet Press Machine R&D Lab Model (1)

- Tips With ADJUST THE PRESSURE OF THE LAB PRESS

- Hydraulic Tablet Press: Comprehensive Guide to Design, Operation, and Applications

- Manual tablet press operating steps and precautions

- Innovative tableting solutions: a comprehensive analysis of laboratory single punch tablet presses